The big room. The hub. Central operations. Whatever they’re called, project team co-location ventures are popping up in increasing numbers as Building Teams face ever-complex projects with tighter schedules and budgets.

The rise of BIM-driven projects, prefabrication, and highly collaborative project delivery methods—such as design-assist and integrated project delivery—have accelerated the demand for in-person, cross-team collaboration.

Successful co-location ventures are not as simple as locking the team in a room for 12-18 months. They require a careful balance of risk sharing, trust, accountability, and scope sharing, as well as a commitment to collaboration.

BD+C reached out to several co-location experts for tips and tricks on maximizing these setups. They offered the following advice:

Hold a “PEP” rally. Experts agree that a kickoff event—with all key stakeholders in the room—is absolutely critical both for building a spirit of camaraderie and for aligning the expectations and objectives for the project.

“We’re finding in co-location environments, the best practitioners in the business are spending a lot of time thinking about high-performance teaming and the sociology behind working together,” says John Tocci, Sr., CEO of Tocci Building Cos., whose firm regularly organizes co-location ventures.

On larger projects, Tocci kicks off co-locations with a day-and-a-half PEP (project execution planning) session facilitated by a process expert and former DuPont chemical engineer. Senior management meets for a half day to sync expectations and objectives for the project. On the second day, the entire team (upwards of 60 people) meets to confirm and prioritize the project objectives, unearth potential pitfalls, and formulate a roadmap for meeting the project goals.

“The whole team, within a few days, tears the project apart,” says Tocci. “People start bearing their professional souls about what it is they’re concerned about when coming on board.”

Make sure all doers are present. On a recent co-location venture for a healthcare client, architect Shepley Bulfinch quickly learned that while all levels of its team were prepared, other firms were not. The biggest issue: firms only sent their team leaders to the co-location collaboration sessions; the professionals doing the actual work stayed back at the home office.

“This was difficult for our staff when they realized that the other parties weren’t sending those doing the work and, therefore, work was not getting done,” says Cathleen Lange, AIA, LEED AP, Principal with Shepley Bulfinch.

Create spaces that are conducive to collaboration. Large, open, flexible spaces are a must so that teams can quickly reconfigure when needed. Tocci recommends plenty of whiteboards, tack-up boards, and blank wall space for pull planning and other Lean process exercises. Also important are creature comforts like clean bathrooms and phone booths so people can duck out to take a personal call.

Offer a mix of meeting room sizes and breakout spaces. “People need spaces so that when a problem arises, a team can go off into an area and start whiteboarding to see what to do with it,” says Tocci.

Be very specific when laying the groundwork for the co-location. You’ll need to have solid answers for the following questions:

• Who’s paying for the space, equipment, technology? The owner? Contractor? Shared cost structure?

• Who’s required to attend? How are they being compensated for their time away from the home office?

• What are the requirements for digital information transfer, responsibilities, and governances?

Strip all branding. “The most successful co-location ventures we’ve had have been completely unbranded, where you don’t see campfires or tribes within the facility,” says Tocci. “That defeats the whole purpose. The goal is total integration, silo-less stationing.”

“Subs” don’t exist in co-location ventures. A healthy co-location culture is one that breaks down the traditional silos. That means ditching the term “subcontractor” in favor of “trade partner,” says Tocci. “It’s not just a warm and fuzzy name,” he says. “They are true partners in the process.”

Master the trust triangle. Building trust across all levels and disciplines is the secret sauce to successful co-location projects. Tocci recommends reading The Five Dysfunctions of a Team: A Leadership Fable (http://amzn.to/2buPW16) to help break down silos and strengthen trust and accountability among project team members.

“Establishing trust among all parties in the co-location room is essential,” adds Lange. “All it takes is one skeptical person to bring the whole room down.”

Incorporate visual cues to maintain accountability. Whether using large-screen monitors or simple signage, presenting real-time performance metrics—burn rates on cash, performance on budget, KPIs, etc.—will help maintain accountability across the team. Even simple traffic lights for tracking major indices like budget and schedule are helpful. “Someone can walk in, look around the room, and within a few minutes they’ll have a sense of the health and vitality of the project,” says Tocci.

Related Stories

BIM and Information Technology | May 26, 2015

Lego-like model building kit was created by an architect for architects

Arckit, as the system is called, was designed to a 1:48 scale, making it easy to create models accurate to the real-life, physical building projected.

BIM and Information Technology | May 26, 2015

Moore's Law and the future of urban design

SmithGroupJJR's Stephen Conschafter, urban designer and planner, discusses his thoughts on the 50th anniversary of Moore's Law and how technology is transforming urban design.

BIM and Information Technology | May 21, 2015

How AEC firms should approach BIM training

CASE Founding Partner Steve Sanderson talks about the current state of software training in the AEC industry and common pitfalls in AEC training.

BIM and Information Technology | May 13, 2015

5 smart tech trends transforming the job site

RFID labor tracking, 360 cameras, and advanced video tools are among the tech innovations that show promise for the commercial construction industry.

BIM and Information Technology | May 10, 2015

How beacons will change architecture

Indoor positioning is right around the corner. Here is why it matters.

BIM and Information Technology | Apr 29, 2015

Self-piloting drone maps out construction sites in Pennsylvania

The system comes with a real-time portal for immediate access to collected data.

BIM and Information Technology | Apr 27, 2015

The construction industry isn't rushing to hop onto the cloud: study

A new poll finds that nearly half of companies aren't planning to shift to cloud-based software to collaborate any time soon.

BIM and Information Technology | Apr 21, 2015

Software tools shouldn't dictate the AEC process

With over 200 solutions on the market, construction software is one of the most complex and fragmented markets, writes Gensler's Mark Thole.

BIM and Information Technology | Apr 9, 2015

A carboard box by Google can bring virtual reality to architecture

The global search engine giant has launched a new product, Google Cardboard, that easily allows users to experience virtual reality.

BIM and Information Technology | Apr 9, 2015

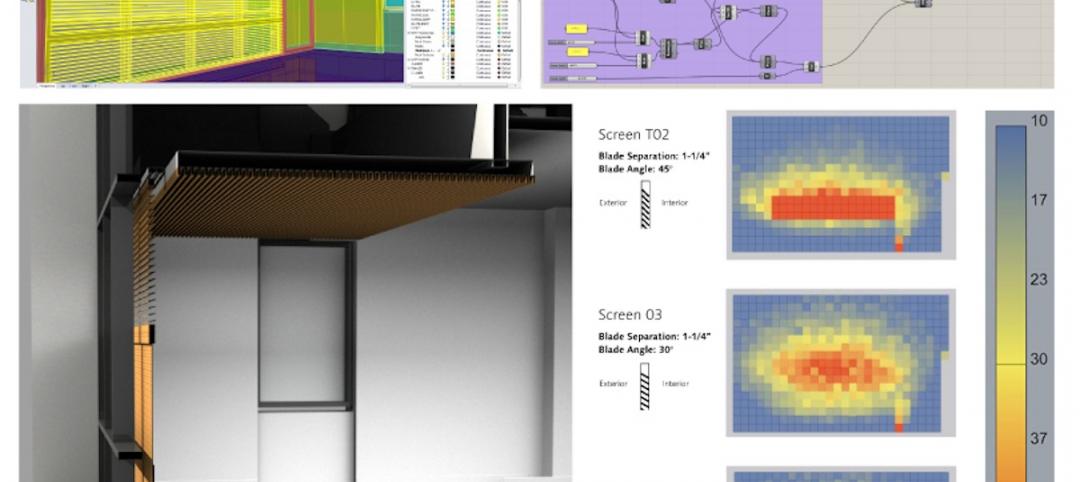

How one team solved a tricky daylighting problem with BIM/VDC tools, iterative design

SRG Partnership's Scott Mooney describes how Grasshopper, Diva, Rhino, and 3D printing were utilized to optimize a daylighting scheme at Oregon State University's new academic building.