3D printers have become invaluable tools for producing much-needed personal protective equipment during the COVID-19 pandemic. Tech companies such as Apple and Blue Origin, manufacturers like Ford Motor Co., and universities such as Duke and Harvard, have been using their printers to churn out face shields for first-line medical workers.

And it’s not just corporations and academia jumping in, either. Former Autodesk CEO Carl Bass and Chris Taggert, who operate a 10,000-sf metal shop in West Berkeley, Calif., recently set up a GoFundMe page to help their meet their goal of producing more than 20,000 shields using 3D printers for areas hit hardest by the coronavirus.

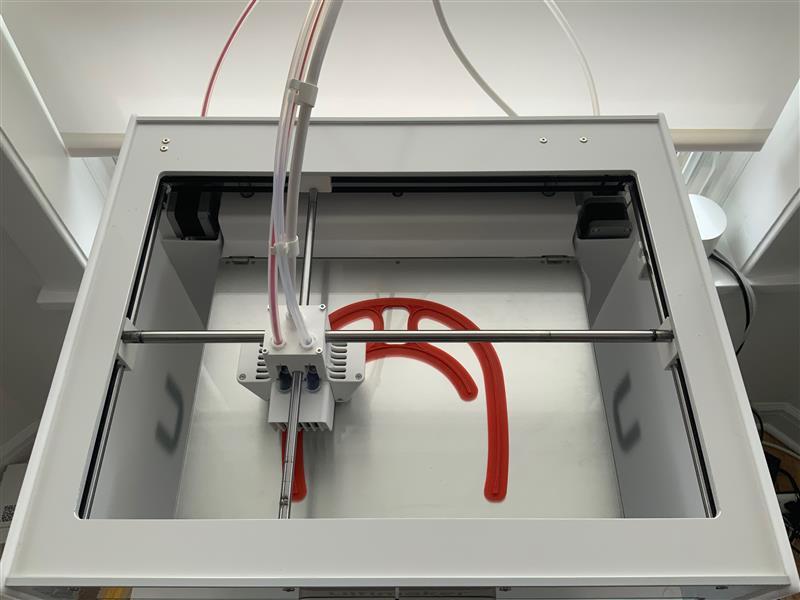

Last Friday, AMITA Health Resurrection Medical Center Chicago received its initial shipment of 20 reusable face shields that its medical staff helped design in collaboration with Chicago-based Krueck + Sexton Architects, which produced the shields on a 3D printer.

Thirty of Krueck + Sexton’s employees—essentially its entire studio—were involved in the initial concept design, which over the past several weeks they discussed during the office’s weekly “Friday Forum.” Ten of those employees were actively involved in sketching and refining the shield design.

The hospital's medical personnel was involved in refining the design of the face shields, whose initial concept Krueck + Sexton's entire studio team worked on.

Project Architect Mariusz Klemens spearheaded this effort after his sister-in-law, Dr. Angelina Slota, a resident at the hospital, told him about Resurrection’s need for more PPEs. He set up a temporary 3D printing operation in his apartment and worked round the clock to produce and assemble the shields. The medical team got involved in testing the prototype in a hospital setting, and providing feedback that guided the design for improved functionality and flexibility.

Klemens has since has purchased a second printer to facilitate production of 80 more shields for the hospital, including its Emergency Department team that put in a request for the personal protection equipment.

The face shield is designed for easy maintenance.

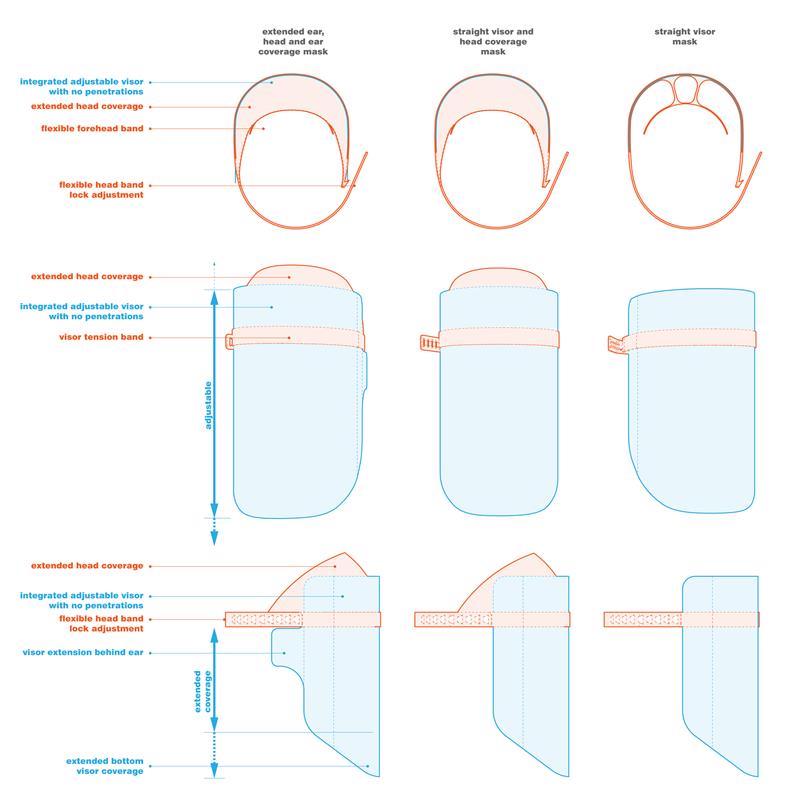

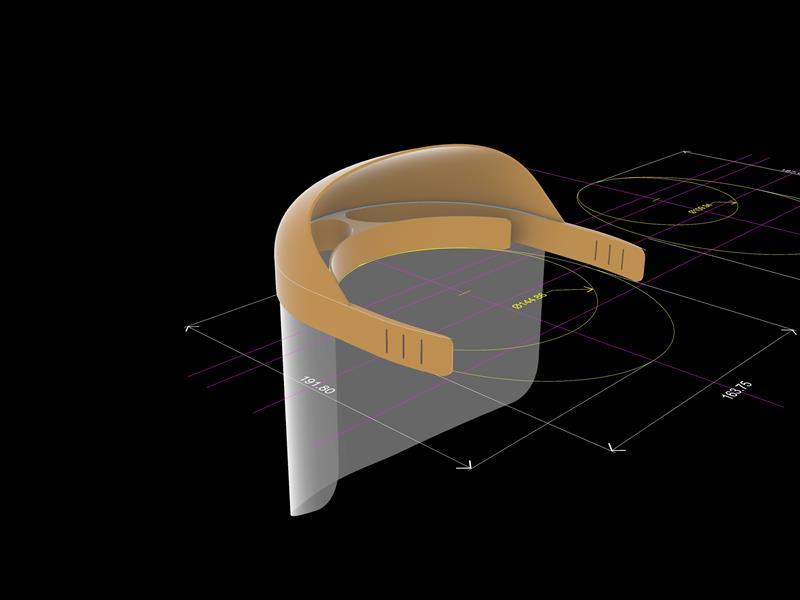

The face shield, according to Krueck + Sexton, has some unique features:

•It provides a continuous barrier, with no holes or screws

•The curved plastic shield extends to the wearer’s chest and covers his or her ears and side of head.

•The shield provides additional coverage to the forehead from the top. And the single-material helmet hooking system can be adjusted to different head sizes.

•The shield itself can be adjusted to accommodate the height of the wearer.

•The face shield has no rubber pieces, and has been designed for easy cleaning.

Related Stories

Coronavirus | Apr 22, 2020

Construction activity in 2020 expected to drop steeply

[Dodge survey] Contractors girding for recession.

Coronavirus | Apr 21, 2020

COVID-19 update: CallisonRTKL, Patriot, PODS, and USACE collaborate on repurposed containers for ACFs

CallisonRTKL and PODS collaborate on repurposed containers for ACFs

Coronavirus | Apr 20, 2020

Virtual site visits help control infection on project sites

As COVID-19 threatens to slow construction work, point cloud technology helps us work safer and faster.

Coronavirus | Apr 19, 2020

IoT system helps contractors keep their distance on the jobsite

Triax Technologies’ wearable Proximity Trace device can be used for contact tracing.

Coronavirus | Apr 19, 2020

A COVID-19 task force focuses on crisis communications

The Castle Group is partnering with leading health experts to help companies factor science and medicine into their response messaging and actions.

Coronavirus | Apr 17, 2020

NMHC Multifamily Construction Survey shows significant delays in apartment construction

Survey asked construction firms how the spread of COVID-19 is affecting construction permitting, starts, completions, materials and labor.

Coronavirus | Apr 17, 2020

The case for public space in the age of COVID-19

As our daily footprint narrows under “stay at home” measures, we must reconsider our relationship with public spaces.

Coronavirus | Apr 16, 2020

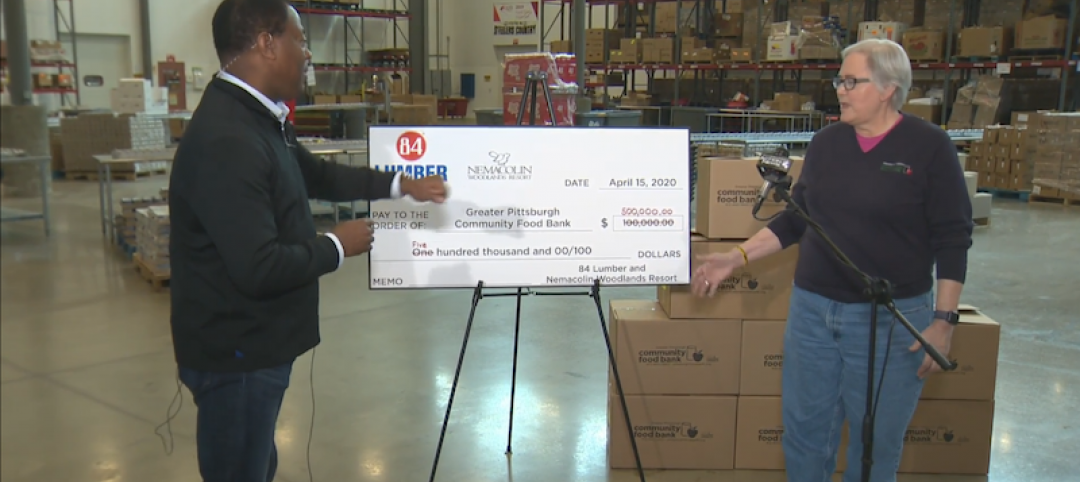

COVID-19: Pennsylvania building products supplier raises $1.2 million for Pittsburgh-area food bank

Pennsylvania building products supplier raises $1.2 million for Pittsburgh-area food bank.

Coronavirus | Apr 15, 2020

How has your work been impacted by COVID-19?

The SMPS Foundation and Building Design+Construction are studying the impact of the coronavirus pandemic on the ability to attain and retain clients and conduct projects, along with other consequences.

Coronavirus | Apr 15, 2020

COVID-19 alert: 93% of renters in professionally managed multifamily housing paid some or all of their rent, says NMHC

In its second survey of 11.5 million units of professionally managed apartment units across the country, the National Multifamily Housing Council (NMHC) found that 84% of apartment households made a full or partial rent payment by April 12, up 15 percentage points from April 5.