3D printers have become invaluable tools for producing much-needed personal protective equipment during the COVID-19 pandemic. Tech companies such as Apple and Blue Origin, manufacturers like Ford Motor Co., and universities such as Duke and Harvard, have been using their printers to churn out face shields for first-line medical workers.

And it’s not just corporations and academia jumping in, either. Former Autodesk CEO Carl Bass and Chris Taggert, who operate a 10,000-sf metal shop in West Berkeley, Calif., recently set up a GoFundMe page to help their meet their goal of producing more than 20,000 shields using 3D printers for areas hit hardest by the coronavirus.

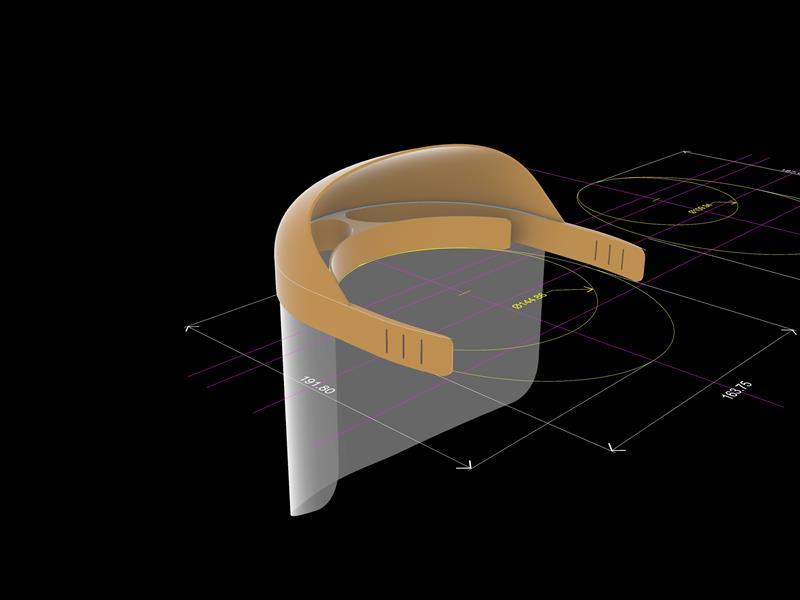

Last Friday, AMITA Health Resurrection Medical Center Chicago received its initial shipment of 20 reusable face shields that its medical staff helped design in collaboration with Chicago-based Krueck + Sexton Architects, which produced the shields on a 3D printer.

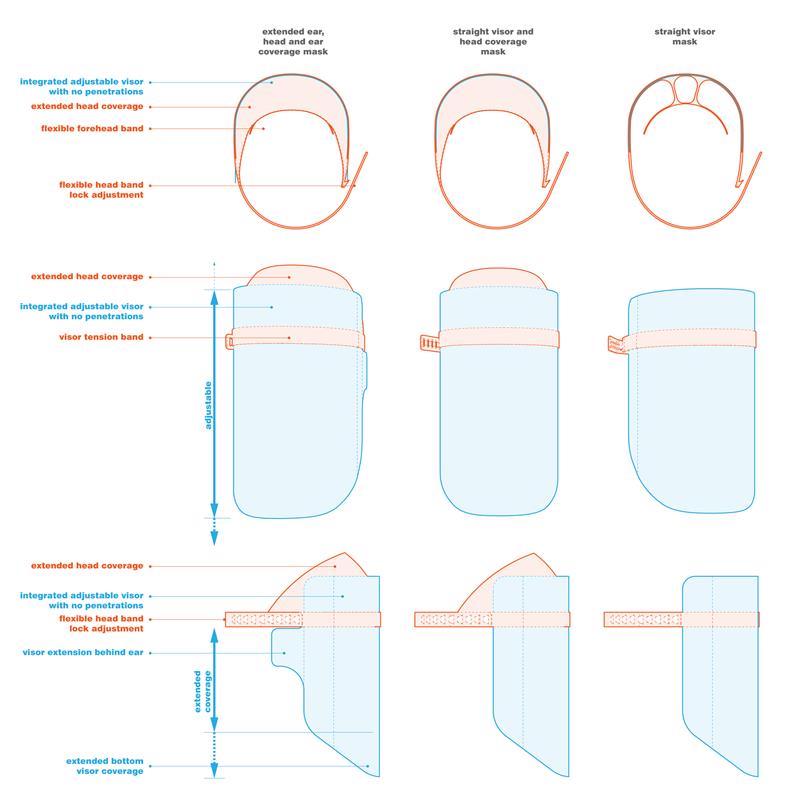

Thirty of Krueck + Sexton’s employees—essentially its entire studio—were involved in the initial concept design, which over the past several weeks they discussed during the office’s weekly “Friday Forum.” Ten of those employees were actively involved in sketching and refining the shield design.

The hospital's medical personnel was involved in refining the design of the face shields, whose initial concept Krueck + Sexton's entire studio team worked on.

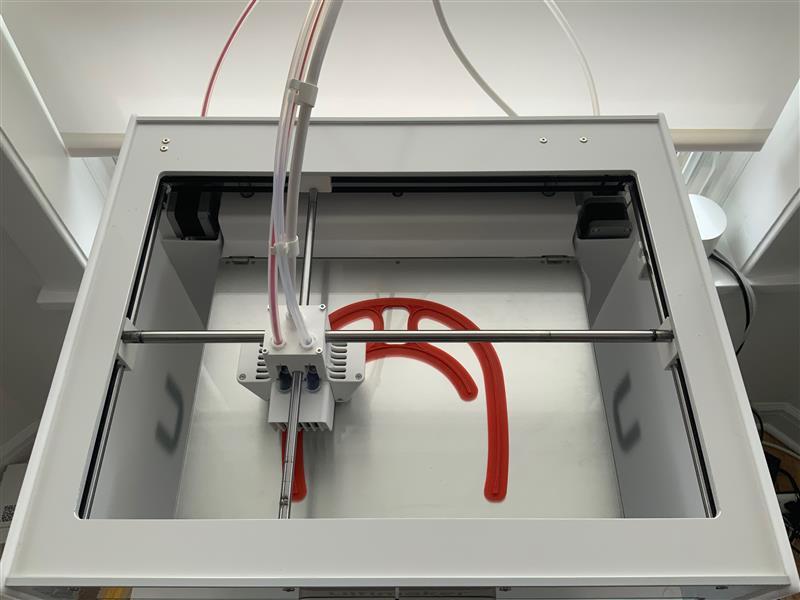

Project Architect Mariusz Klemens spearheaded this effort after his sister-in-law, Dr. Angelina Slota, a resident at the hospital, told him about Resurrection’s need for more PPEs. He set up a temporary 3D printing operation in his apartment and worked round the clock to produce and assemble the shields. The medical team got involved in testing the prototype in a hospital setting, and providing feedback that guided the design for improved functionality and flexibility.

Klemens has since has purchased a second printer to facilitate production of 80 more shields for the hospital, including its Emergency Department team that put in a request for the personal protection equipment.

The face shield is designed for easy maintenance.

The face shield, according to Krueck + Sexton, has some unique features:

•It provides a continuous barrier, with no holes or screws

•The curved plastic shield extends to the wearer’s chest and covers his or her ears and side of head.

•The shield provides additional coverage to the forehead from the top. And the single-material helmet hooking system can be adjusted to different head sizes.

•The shield itself can be adjusted to accommodate the height of the wearer.

•The face shield has no rubber pieces, and has been designed for easy cleaning.

Related Stories

Coronavirus | Jun 9, 2020

Going viral: How the coronavirus pandemic could change the built environment

Architecture and construction firms—and their clients—are asking new questions about infection control as it pertains to people assembly, building wellness, and technology.

Fire and Life Safety | Jun 9, 2020

NFPA develops business reopening checklist for fire and life safety measures

The new checklist helps building owners and facility managers ensure fire and life safety as businesses prepare to re-open amid the coronavirus pandemic.

Coronavirus | Jun 9, 2020

CannonDesign unveils COVID Shield

As the world evolves its response to the COVID-19 pandemic, one clear reality is testing for the virus will be part of our daily lives for the foreseeable future.

Coronavirus | Jun 5, 2020

3 strategies to improve the wellness of building systems and gain tenant trust

Three operational issues that must be prioritized for every building in order to achieve tenant trust are air quality/ventilation, relative humidity, and building commissioning.

Coronavirus | Jun 2, 2020

5 ways to improve hand washing and minimize germs in public restrooms

Bradley Corp. offers five upgrades to make public restrooms more sanitary.

Coronavirus | Jun 2, 2020

Perkins and Will, Healthy Building Network advise against the use of antimicrobial building products

Even during a pandemic, antimicrobial building products may do more harm than good.

Coronavirus | May 30, 2020

A welcoming entry-point for wellness screening anywhere

Modular WorkWell™ ecosystem can process up to 40 people per minute.

Coronavirus | May 29, 2020

Black & Veatch, DPR, Haskell, McCarthy launch COVID-19 construction safety coalition

The NEXT Coalition will challenge engineering and construction firms to enhance health and safety amid the Coronavirus pandemic.

Coronavirus | May 28, 2020

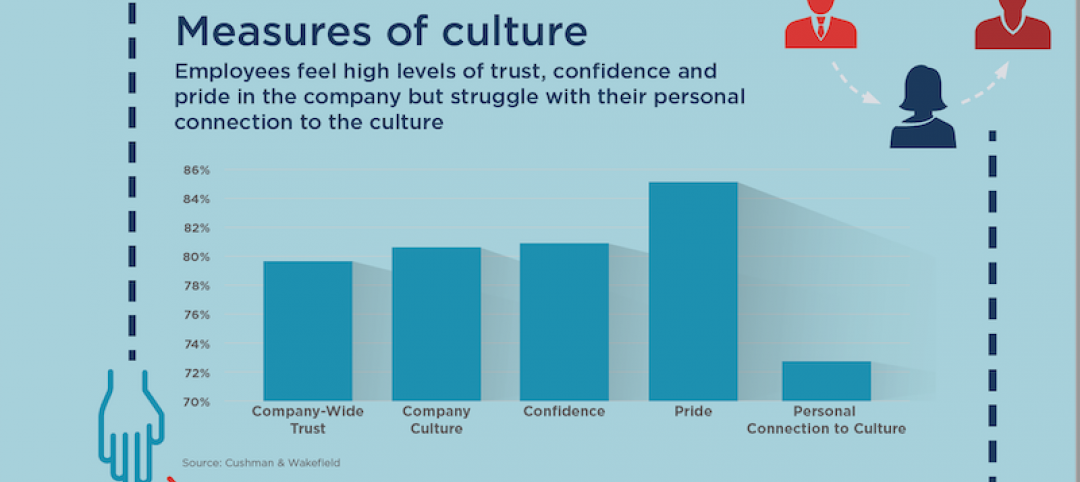

Cushman & Wakefield report examines work-at-home pros and cons

The office, now part of a larger workplace ecosystem, still reinforces employees’ connections with their companies.

Coronavirus | May 27, 2020

Clean is the new Green as U.S. hospitality sector inches closer to reopening

Three design firms share their takes on what will make customers more comfortable about returning.