Glass is heat-treated for two reasons: the first is to increase its strength to resist external stresses such as wind and snow loads, or thermal loads caused by the sun’s energy.

The second is to temper glass so that it meets safety glazing requirements defined by applicable codes or federal standards.

Following are a dozen quick tips about tempered and heat-strengthened glass, including why the strongest glass isn’t always the best glass for a given application.

1. Fabrication first. Because of the high internal stresses caused by heat-strengthening or tempering glass, all fabrication, including cutting, hole-drilling, notching or edge treatment, must be performed before glass is heat-treated.

2. Defining heat-treated glass. In North America, the standard specification for heat-treated glass is ASTM C1048 Standard Specification for Heat-Strengthened and Fully Tempered Glass. In general, heat-treated glass is at least two to four times stronger than annealed (untreated) glass.

3. Rate of cooling determines strength. During heat treatment, annealed (untreated) glass lites are heated to approximately 1,200 degrees F, then “quenched” in cold air. Cooled rapidly, glass tempers. Slower cooling produces heat-strengthened glass.

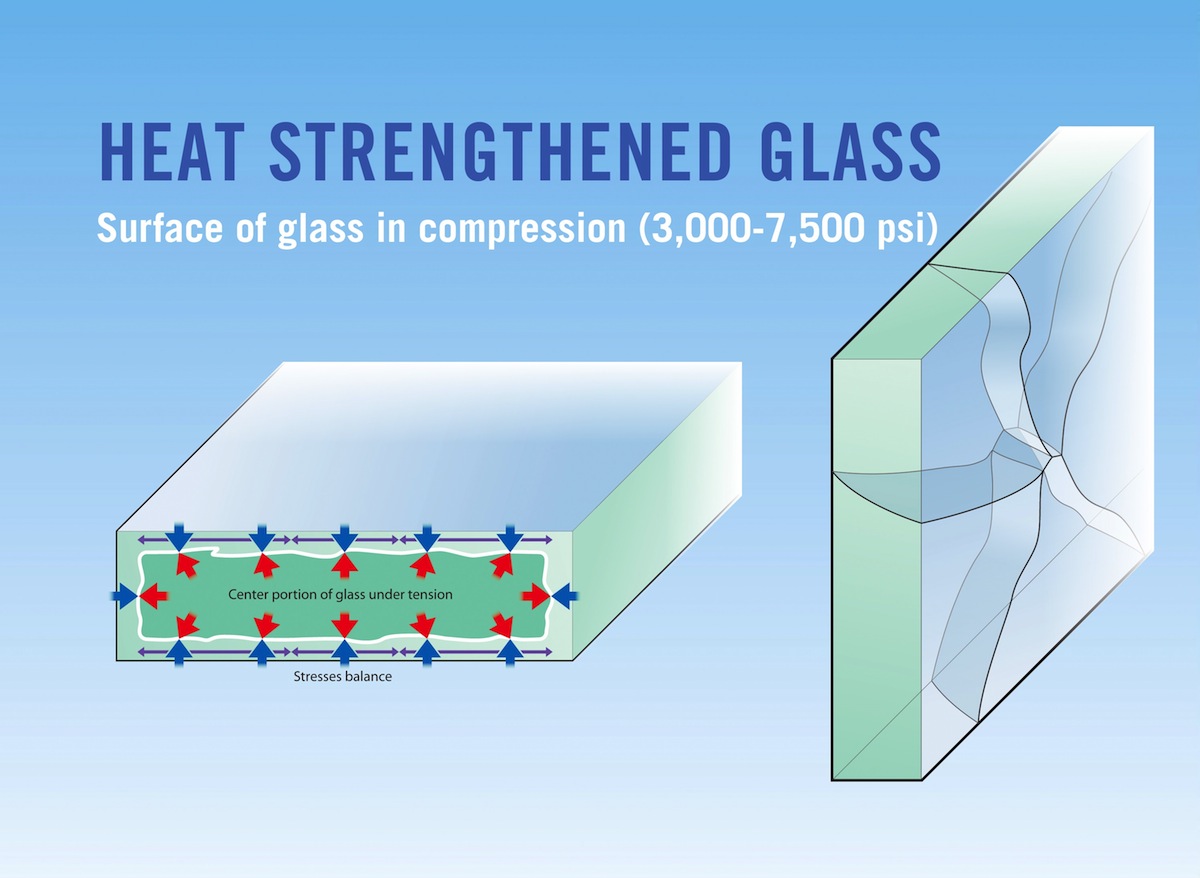

4. Tempered is stronger. Tempered glass has a minimum surface compression of 10,000 pounds-per-square-inch (psi) and minimum edge compression of 9,700 psi, according to ASTM C1048. That makes it about four times stronger than annealed glass. Heat-strengthened glass has surface compression of 3,500 to 7,500 psi, about twice as strong as annealed glass, with no edge compression standard.

5. Tempered glass is safety glass. When broken by impact, fully tempered glass shatters into tiny particles, reducing the potential for serious injury by flying shards of glass. For this reason, building codes require safety glazing in specific locations.

6. Stronger, yet more vulnerable. Ironically, the rapid temperature change that gives tempered glass its compression strength may also cause it to shatter, seemingly without warning. On rare occasions, tiny inclusions, including nickel-sulfide, may be present in glass, which can expand during heat treatment, then stop when the glass is cooled and resume growth when the glass is exposed to high in-service temperatures (such as on the sunny exposure of a building). This “phase change” can cause tempered glass to shatter. Heat-strengthened glass is cooled more slowly; consequently, inclusions do not experience a phase change, which essentially eliminates the possibility of spontaneous glass failure.

7. Heat-strengthened glass is not a safety glass. Though heat-strengthened glass may meet requirements for wind, snow and thermal loads, it is not considered a safety glazing. Heat-strengthened glass does not shatter when broken, but fractures into larger, sharper pieces that can become projectiles in a tornado, hurricane, explosion or fire.

8. Avoiding fall-out. Because it does not shatter, heat-strengthened glass tends to remain in the framing system after it is damaged, which makes it a better choice for applications where glass fall-out is a concern.

9. Lamination for consideration. Laminated interlayers, required for overhead glazing, can be used with annealed, heat-strengthened or tempered glass to combine several safety advantages into a single glazing solution, including less risk of spontaneous breakage and glass fall-out, and increased resistance to wind loads, snow loads and thermal stress.

10. Distorted views. Heat-treatment can generate subtle roller waves in glass, which are more likely to occur in tempered glass than in heat-strengthened glass. This can cause heat-treated glass to distort reflected images, a problem that may be exacerbated when it is used in glazing units with multiple lites or a laminated interlayer.

11. Edge quality is critical. Poor edge quality – or edge damage during fabrication, delivery or installation – makes glass more likely to break, which can offset or negate any benefit associated with heat-strengthening or tempering.

12. Stronger isn’t always better. Although tempered glass is strongest, PPG recommends its use only where required by code as a safety glazing or for thermal stress or wind load. For other applications, annealed or heat-strengthened glass is recommended to reduce distortion and the risk of fallout and spontaneous breakage.

What is tempered glass?

Tempered glass, also known as toughened glass, goes through a process of extreme heating and rapid cooling during the manufacturing process. It is much stronger and harder than normal glass.

What is annealed glass?

Annealed glass, also known as standard glass, has been thermally treated and then slowly cooled. Annealed glass is a softer glass and is generally used when cost is a greater concern than strength or safety.

To learn more about the differences between tempered and heat-strengthened glass, or to find the best recommendation for a specific application, visit the PPG Glass Education Center at www.educationcenter.ppg.com.

Related Stories

| Oct 7, 2011

GREENBUILD 2011: UL Environment releases industry-wide sustainability requirements for doors

ASSA ABLOY Trio-E door is the first to be certified to these sustainability requirements.

| Oct 7, 2011

GREENBUILD 2011: Transparent concrete makes its North American debut at Greenbuild

The panels allow interior lights to filter through, from inside.

| Oct 6, 2011

GREENBUILD 2011: Dow Corning features new silicone weather barrier sealant

Modular Design Architecture >Dow Corning 758 sealant used in GreenZone modular high-performance medical facility.

| Oct 6, 2011

GREENBUILD 2011: Kingspan Insulated Panels spotlights first-of-its-kind Environmental Product Declaration

Updates to Path to NetZero.

| Oct 5, 2011

GREENBUILD 2011: Sustainable construction should stress durability as well as energy efficiency

There is now a call for making enhanced resilience of a building’s structure to natural and man-made disasters the first consideration of a green building.

| Oct 5, 2011

GREENBUILD 2011: Roof hatch designed for energy efficiency

The cover features a specially designed EPDM finger-type gasket that ensures a positive seal with the curb to reduce air permeability and ensure energy performance.

| Oct 4, 2011

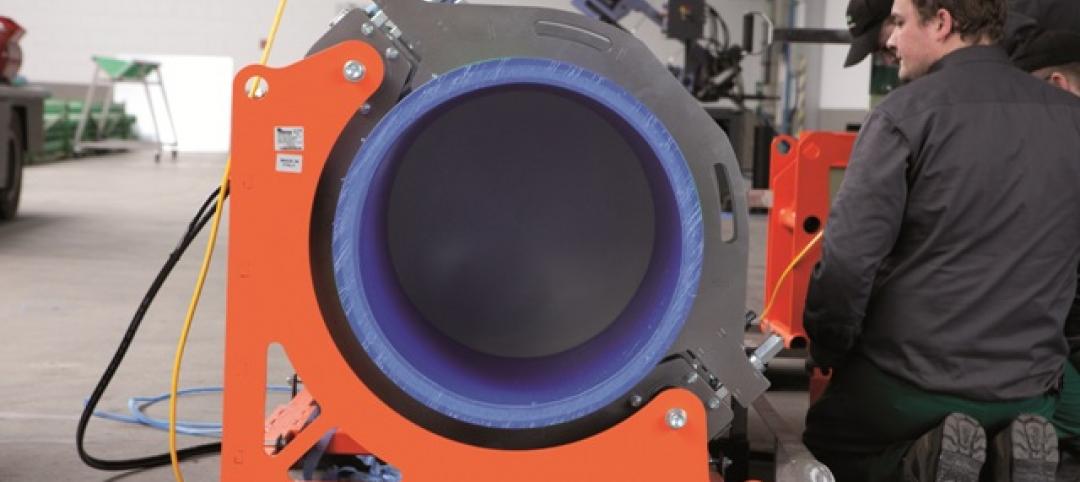

GREENBUILD 2011: Large diameter polypropylene-random pipe unveiled

Available in North America for large scale piping applications including high-rise buildings, large chilled water systems, district energy, and water mains.

| Oct 4, 2011

GREENBUILD 2011: Wall protection line now eligible to contribute to LEED Pilot Credit 43

The Cradle-to-Cradle Certified Wall Protection Line offers an additional option for customers to achieve LEED project certification.

| Sep 27, 2011

Steel Joist Institute announces October webinar on Open Web Steel Joists

Webinar participants can earn 0.15 CEUs or 1.5 PDHs.

| Sep 14, 2011

More than 200 events planned for third annual SteelDay September 23

Special events in major cities including New York City, Chicago, Washington, D.C., and more.