Raised flooring was introduced years ago for use in data centers, where the ability to easily move power and data cabling under the floor was a big plus. At the time, it was not unusual for raised floors to have less than a solid feel; this was chiefly due to thin floor panel material, which often resulted in a squeaky, hollow sound as occupants walked on the floor. Contractors were not accustomed to the demands of raised-floor construction, leading to poor performance.

Today, general contractors and subcontractors have the know-how to install these systems to high standards. Properly installed, raised flooring feels as sturdy as any other flooring, and underfloor air distribution (UFAD), often combined with air displacement ventilation, is gaining acceptance among building owners and designers. “Ten or twelve years ago, UFAD was perceived as risky, but not anymore,” says David Atwood, general manager of Boston-based contractor Integrated Interiors. “On major gut rehabs or new construction, it is getting more consideration than we’ve ever seen.” (Note: For the purposes of this article, “UFAD” is used interchangeably with “underfloor air displacement ventilation.”)

APPLICATION IN NUMEROUS BUILDING TYPES

The UFAD technology’s multiple advantages make it an increasingly popular choice for a variety of building types, including offices, schools, college classrooms, libraries, casinos, and, of course, data centers.

UFAD can help reduce the amount of construction materials used in a project, particularly on high-rise projects. Unlike overhead HVAC, underfloor heating and cooling uses little ductwork, so the amount of sheet metal used is greatly reduced. Moreover, the elimination of overhead ducts means plenum heights can be reduced by six inches or more per floor. “We have modeled an 11-story building, and it gained an entire floor from the reduced plenum heights,” Atwood says. The savings on structural steel, envelope elements, and curtain wall materials adds up as building height increases.

One of the most important benefits of raised floor systems is that they can easily be reconfigured by moving floor tiles and diffusers to different locations, and cabling can be accessed and moved easily under the floor. As a result, maintenance staff can rearrange workstations for new tenants without drilling holes and disassembling portions of the ceiling. In an office building with high tenant turnover, the resulting savings in labor costs over the years can be considerable. And because floor outlets are easy tomove, there’s no need to buy cubicles with power outlets, which cost considerably more than nonpowered units.

UFAD systems use much lower static air pressure to heat or cool a space than conventional overhead HVAC systems. Thus, the power needed to run fans is reduced, thereby saving energy. Some UFAD manufacturers claim that total HVAC power savings can be as much as 20-30% compared with overhead systems, but that’s probably overstating the case, according to Tom Webster, research specialist with the Center for the Built Environment at the University of California, Berkeley. He says that, in a typical office environment, the CBE has measured HVAC energy savings from UFAD systems in the 10-15% range under ideal conditions using currently available technology. Still, 10-15% energy savings is nothing to sneeze at.

However, Webster cautions that because no two buildings are alike, it is extremely difficult to compare the energy use of an overhead system with a UFAD system. Variables such as climate, ceiling height, system configuration, and the presence of other energy-conserving elements in the building complicate the equation. One thing is clear, says Webster: cooling climates will reap higher energy savings than heating climates from UFAD.

With some tweaking, it is possible to improve UFAD energy performance, Webster adds. If diffusers are positioned just right on the floor, and if occupants and maintenance staff adjust the diffusers properly—actions more honored in the breach than in the observance—greater energy savings can be realized.

UFAD systems may also contribute to improved thermal comfort and air quality. Surveys have shown a higher rate of satisfaction when occupants have more control over heating and cooling of their individual spaces, and some studies have found improved productivity in UFAD buildings. One reason: lower static air pressure means much less air mixing compared with overhead systems. Thus, when someone sneezes, germs don’t travel as far as they would in an overhead system. That’s one reason that UFAD can contribute to a LEED credit for indoor air quality.

FIRST COST VS. LIFE CYCLE COST

The question of first cost vs. life cycle cost for UFAD systems is somewhat controversial and depends on what assumptions are being made. UC Berkeley’s Center for the Built Environment says that its baseline assumptions yielded a cost premium of $3.50/gsf between the median UFAD system and the baseline overhead system. In cases where the owner or designer calls for a raised floor to make moving cabling and power lines easier, however, installing UFAD may prove less costly than going overhead, according to the CBE’s Webster. When all cost factors are accounted for over the life of a building, it is possible for UFAD to come out ahead in total cost of ownership. But, again, it depends a lot on the assumptions that have gone into the calculation.

It is also the case that, with the exception of total gut renovation projects, underfloor air distribution systems are usually cost-prohibitive for reconstruction projects. Perhaps the biggest possible downside to the technology, though, is that improper installation will reduce system efficiency, raise energy costs, and reduce thermal comfort for occupants. While it doesn’t take a genius to install UFAD correctly, it does mean that general contractors and the building trades must pay attention to the details.

Here, according to experts consulted for this article, are a number of factors to keep in mind when employing underfloor air distribution systems in your projects.

KEYS TO PROPER UFAD INSTALLATION

Proper installation of UFAD systems requires attention to detail, rigorous scheduling, and job site cleanliness—all responsibilities that fall primarily on the general contractor, who must educate all the members of the Building Team and ensure that the certain critical factors are addressed.

Develop an efficient layout. Projects that don’t take this crucial first step may run into interface conflicts and poor coordination among the trades. Here’s where BIM/3D models may streamline the process.

Finish the overhead work first. Coordinate construction trades to get most overhead work out of the way as early as possible. Scissor lifts, staging, and ladders all pose a safety risk when working around exposed floor openings.

Educate your subcontractors. Subcontractors must understand that they are working in areas that will become part of the air delivery system. Work cleanliness and the proper sealing of all penetrations are essential to whole building performance.

Get the flooring team in early. Flooring teams should be involved right after the concrete slab is poured. Most floor plans for UFAD projects incorporate a blend of raised flooring and conventional concrete slabs. Merging a raised flooring system with a fixed concrete slab requires a thorough survey and tactical benchmarking. The slab may directly meet the raised floor around the building core, such as near the elevators, and concrete may have to be ground down to provide an even seam.

Draw a map. Mark out a dot grid with spray paint on the slab to identify where pedestal bases are to be located within the floor plate. Skipping this step can lead to installation conflicts. “You don’t want to locate diffusers under a piece of furniture,” warns Scott Alwine, LEED AP, with Tate Access Floors, Jessup, Md.

Position cutouts and power service correctly. After studying the floor plate design and furniture layout, the team must maintain close communication with the panel manufacturer so that cutouts, where power and data lines will enter, are properly located. With floor panels installed, electrical and mechanical trades can install service boxes with power and data cabling guided through pre-cut openings in floor panels.

Eliminate gaps in the floor. Rigorous quality controls should be in place to ensure that there are no gaps in the underfloor air plenum. “You have to make sure everything under the floor is sealed,” Alwine says. “That includes utility closets, where cabling comes through the floor, where the floor meets the elevator, and around columns.”

Make sure the final layer of flooring is perfect. There are many choices of finishes on raised floor tiles, including terrazzo and synthetic materials, but carpet tiles that overlap the seams of floor panels are the most common. The carpet installer should use the minimum amount of adhesive necessary, so that the tiles can be removed easily when access to the underfloor is needed. “You also want to make sure that the carpet tiles line up with the floor panels for easy removal and replacement,” Alwine says. BD+C

UFAD Contributes to Office Building’s LEED Platinum Rating

Great River Energy’s 165,000-sf LEED Platinum headquarters in Maple Grove, Minn., is a showcase for green building systems, including underfloor air distribution. Heating and cooling are fed by a geothermal system from the waters of neighboring Arbor Lake.

“It may be the first time that geothermal has been combined with underfloor displacement ventilation in the U.S.,” says Doug Pierce, AIA, LEED AP, a senior associate with the Minneapolis office of architect Perkins+Will. Air is delivered at a constant 67?F. “During many days in spring and fall, there is very little use of compressors, saving a fair amount of energy,” he says.

UFAD with displacement ventilation helped the project earn a LEED point for indoor air quality. “To earn that point, you have to provide 30% more fresh air than the ASHRAE baseline,” Pierce says. Displacement ventilation is 20% more effective at delivering fresh air to the breathing zone than conventional mixing systems. Thus, you only need to bring in another 10% more fresh air to deliver a total 30% more fresh air to the occupant space as compared to conventional mixing ventilation systems.

Having the raised floor also made it more economical to specify 10-foot ceilings—a foot higher than usual—to enhance the daylighting in the building. “We used a post-tension slab that provided a total structural depth of only 10 inches,” Pierce says. Normally, he says, his firm would not recommend a post-tension system for institutional clients because such systems are hard to core drill for future services, and you end up with a 30-inch-deep structural system. With the raised floor, he says, “cabling and utilities could be moved around easily, so we used the post-tension slab, resulting in a high ceiling and floor-to-floor heights that were just a little less than typical.” As a result, the design gained an extra foot of interior height without increasing the exterior wall height.

Related Stories

Green | Apr 8, 2024

LEED v5 released for public comment

The U.S. Green Building Council (USGBC) has opened the first public comment period for the first draft of LEED v5. The new version of the LEED green building rating system will drive deep decarbonization, quality of life improvements, and ecological conservation and restoration, USGBC says.

Codes and Standards | Apr 8, 2024

Boston’s plans to hold back rising seawater stall amid real estate slowdown

Boston has placed significant aspects of its plan to protect the city from rising sea levels on the actions of private developers. Amid a post-Covid commercial development slump, though, efforts to build protective infrastructure have stalled.

Sustainability | Apr 8, 2024

3 sustainable design decisions to make early

In her experience as an architect, Megan Valentine AIA, LEED AP, NCARB, WELL AP, Fitwel, Director of Sustainability, KTGY has found three impactful sustainable design decisions: site selection, massing and orientation, and proper window-to-wall ratios.

Brick and Masonry | Apr 4, 2024

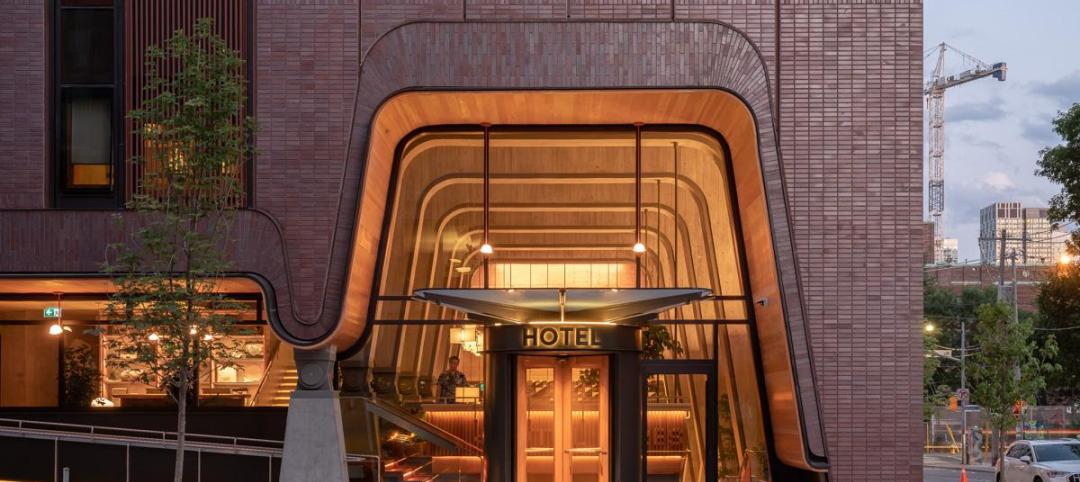

Best in brick buildings: 9 projects take top honors in the Brick in Architecture Awards

The Ace Hotel Toronto, designed by Shim-Sutcliffe Architects, and the TCU Music Center by Bora Architecture & Interiors are among nine "Best in Class" winners and 44 overall winners in the Brick Industry Association's 2023 Brick in Architecture Awards.

Retail Centers | Apr 4, 2024

Retail design trends: Consumers are looking for wellness in where they shop

Consumers are making lifestyle choices with wellness in mind, which ignites in them a feeling of purpose and a sense of motivation. That’s the conclusion that the architecture and design firm MG2 draws from a survey of 1,182 U.S. adult consumers the firm conducted last December about retail design and what consumers want in healthier shopping experiences.

Healthcare Facilities | Apr 3, 2024

Foster + Partners, CannonDesign unveil design for Mayo Clinic campus expansion

A redesign of the Mayo Clinic’s downtown campus in Rochester, Minn., centers around two new clinical high-rise buildings. The two nine-story structures will reach a height of 221 feet, with the potential to expand to 420 feet.

Sports and Recreational Facilities | Apr 2, 2024

How university rec centers are evolving to support wellbeing

In a LinkedIn Live, Recreation & Wellbeing’s Sadat Khan and Abby Diehl joined HOK architect Emily Ostertag to discuss the growing trend to design and program rec centers to support mental wellbeing and holistic health.

Architects | Apr 2, 2024

AE Works announces strategic acquisition of WTW Architects

AE Works, an award-winning building design and consulting firm is excited to announce that WTW Architects, a national leader in higher education design, has joined the firm.

Office Buildings | Apr 2, 2024

SOM designs pleated façade for Star River Headquarters for optimal daylighting and views

In Guangzhou, China, Skidmore, Owings & Merrill (SOM) has designed the recently completed Star River Headquarters to minimize embodied carbon, reduce energy consumption, and create a healthy work environment. The 48-story tower is located in the business district on Guangzhou’s Pazhou Island.

K-12 Schools | Apr 1, 2024

High school includes YMCA to share facilities and connect with the broader community

In Omaha, Neb., a public high school and a YMCA come together in one facility, connecting the school with the broader community. The 285,000-sf Westview High School, programmed and designed by the team of Perkins&Will and architect of record BCDM Architects, has its own athletic facilities but shares a pool, weight room, and more with the 30,000-sf YMCA.