Photo credit: alanblakely.com

Two Schools Go for Bold Color and Eye-Catching Design

Metal wall panel systems are affordable, easy-to-install and offer endless design opportunities. With a variety of finishes and rib patterns, they can be used alone or in combination to create attractive lines and shadows for the exterior of any building. Additionally, aluminum wall panels can be perforated for use in equipment screen applications or over graphics.

Del Valle High School

The new Career and Technical Education Center (CTEC) on the campus of Del Valle High School in Del Valle, Texas, includes some very high-tech features. These include a health-science simulation lab and mock courtroom, along with automotive-repair and welding facilities. School administrators wanted an exterior that would reflect their future-focused programs and maintain its good looks over time. Metal cladding panels met both these requirements, and, as appropriate for the school’s mission, installers had to call on their own technical skills to put them into place.

Del Valle’s CTEC is a 64,000 sq. ft., two-story facility that upgrades the school’s career-focused programming. Students are able to earn 23 different industry-recognized certifications and even college credit hours in a range of subject areas. Approximately 2,000 of the school’s 3,330 students take some classes in the center.

Photo credit: alanblakely.com

With the sophistication and expense required to outfit the school’s interior spaces, designers with Austin, Texas-based Pfluger Architects needed to specify economical exterior materials. The combination of masonry and metal wall panels they chose ties the CTEC to the existing high school and to the recently added fine arts and athletics facilities – also designed by Pfluger. They specified Petersen’s PAC-CLAD Highline S1 panels to clad the upper two-thirds of the structure. The mix of finishes and profiles add visual interest and a high-tech appeal, with colors that pop and installation detailing that creates unique shadow effects.

For example, 0.22-gauge steel panels in three custom red finishes – Cardinal, Ron and Tor – clad protruding window bays, a corner stairwell and the automotive bays. The rows of vertically mounted panels in alternating finishes create a shadow-suggesting ripple effect. Most of the remaining wall surface is clad in similar, horizontally running panels featuring a Bone White finish, with the panels that define the window areas finished in Cityscape. `

All of the panels are installed at varying depth, which enhances shadowing throughout the day. According to Dallas Goodman, representative with the installing Texas Roofing Co. of Round Rock, Texas, designers specified the red panels to be installed 2 in. from the exterior substrate, with the Cityscape panels 3 in. from the substrate and Bone panels 7 in. from the substrate.

“In the initial design stage, we discussed what they were looking for and the depth of the panels,” he said. “The red panels repeat a pattern every fifty-second panel, and the architect had that on the drawings.”

The process of ensuring all of the panels were installed at the correct distance from the substrate wall was a new experience for Goodman. “Typically, you might have a fascia band” with a similar effect, he said. “But something like this – this is the first I’ve done.”

In total, 40,300 sq. ft. of Petersen’s PAC-CLAD wall panels were used in the project, along with 3,500 sq. ft. of 24-gauge steel Tite-Loc Plus standing seam panels used as canopy roofing over the school’s automotive bays. Goodman says the company played a key role in the project’s success.

“Petersen did our shop drawings,” he said. “All of it was custom-run, except the Bone White and Cityscape panels, so they were integral in making sure we had what we needed, onsite, when we needed it.”

Photo credit: alanblakely.com

Doris M. Reed Elementary School

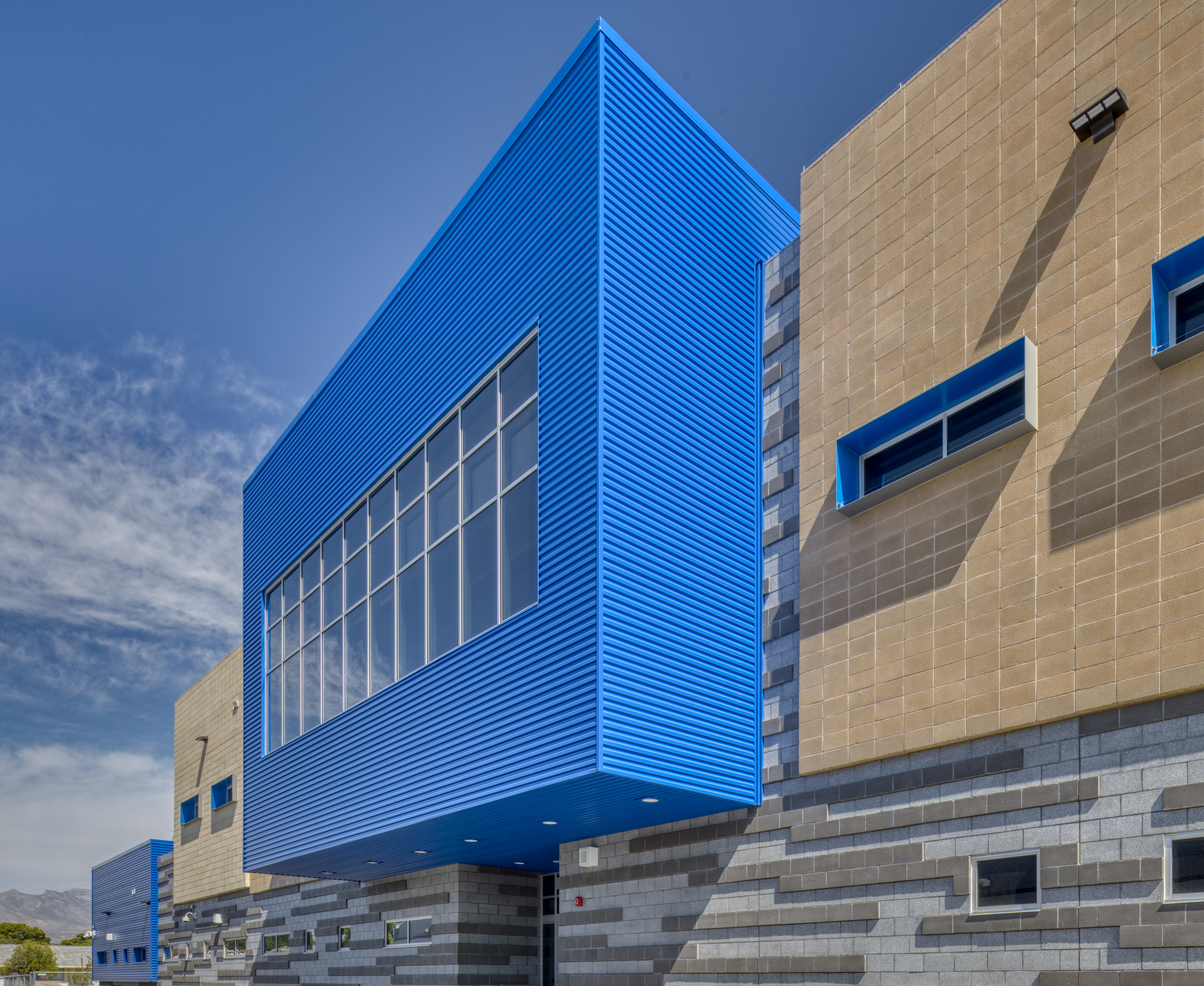

The Doris M. Reed Elementary School in Las Vegas was on a fast track: the design contract was signed in June 2017 and the new building welcomed its first students in August of the next year. Despite what was obviously a speedy construction schedule, the finished structure features a strong sense of style.

Designed by architects from Gensler’s Las Vegas office, the façade incorporates a standard palette of public-school materials: concrete masonry units and metal wall panels. But the end result is anything but generic, thanks to the dynamic dimensionality created through the use of bump-outs and overhangs and layered masonry courses. Then there’s the prominence of a particularly vibrant blue hue – the signature color of the school’s Roadrunner team-sports mascot.

Photo credit: alanblakely.com

For the custom blue wall panel-cladded window bays and the building’s entrance, Gensler’s designers opted for Petersen’s PAC-CLAD Precision Series HWP panels in 24-gauge steel. While a different manufacturer’s product initially was specified, installers with Andy Russo Jr. Inc., recommended a switch to a company whose products they knew and trusted.

“I offered Petersen, and they accepted,” says Andy Russo, Jr., owner of the company that bears his name. “I’ve been dealing with Petersen since the early 1990s. I like their material, and any issues I’ve ever had, they’ve taken care of.”

Russo’s crew performed some custom work to bring the project together, including fabricating the perforated panels used to shelter an exterior staircase. “We custom-made our miters, and we had flashing and counter flashing where we tied into the block,” Russo says. Further craftsmanship can be seen in the lack of seams across the panels’ 45-ft. runs. “Other than the outside miter, we did it all as continuous-length.”

For more information on metal wall panel systems, visit PAC-CLAD.

CONTACT:

Phone: 800-PAC-CLAD

Email: info@PAC-CLAD.com

Related Stories

75 Top Building Products | Nov 30, 2022

75 top building products for 2022

Each year, the Building Design+Construction editorial team evaluates the vast universe of new and updated products, materials, and systems for the U.S. building design and construction market. The best-of-the-best products make up our annual 75 Top Products report.

Multifamily Housing | Sep 15, 2022

Toronto’s B-Line Condominiums completed using prefabricated panels

B-Line Condos, Toronto, completed using Sto Panel Technology.

Sponsored | BD+C University Course | Aug 24, 2022

Solutions for cladding performance and supply issues

This course covers design considerations and cladding assembly choices for creating high-performance building envelopes — a crucial element in healthy, energy-efficient buildings.

Building Materials | Aug 3, 2022

Shawmut CEO Les Hiscoe on coping with a shaky supply chain in construction

BD+C's John Caulfield interviews Les Hiscoe, CEO of Shawmut Design and Construction, about how his firm keeps projects on schedule and budget in the face of shortages, delays, and price volatility.

Cladding and Facade Systems | Jul 5, 2022

Petersen opens new PAC-CLAD manufacturing facility in Washington

Petersen continues to expand the reach of its trusted PAC-CLAD brand by opening a manufacturing facility in Bonney Lake, Wash. The 57,000-sq.-ft. facility shipped its first order in May, and will be fully operational in early 2023.

Sponsored | BD+C University Course | May 5, 2022

Designing with architectural insulated metal wall panels

Insulated metal wall panels (IMPs) offer a sleek, modern, and lightweight envelope system that is highly customizable. This continuing education course explores the characteristics of insulated metal wall panels, including how they can offer a six-in-one design solution. Discussions also include design options, installation processes, code compliance, sustainability, and available warranties.

Sponsored | BD+C University Course | May 3, 2022

For glass openings, how big is too big?

Advances in glazing materials and glass building systems offer a seemingly unlimited horizon for not only glass performance, but also for the size and extent of these light, transparent forms. Both for enclosures and for indoor environments, novel products and assemblies allow for more glass and less opaque structure—often in places that previously limited their use.

Sponsored | BD+C University Course | Apr 10, 2022

Designing with commercial and industrial insulated metal wall panels

Discover the characteristics, benefits and design options for commercial/industrial buildings using insulated metal panels (IMPs). Recognize the factors affecting panel spans and the relationship of these to structural supports. Gain knowledge of IMP code compliance.

Multifamily Housing | Apr 7, 2022

Ken Soble Tower becomes world’s largest residential Passive House retrofit

The project team for the 18-story high-rise for seniors slashed the building’s greenhouse gas emissions by 94 percent and its heating energy demand by 91 percent.

Cladding and Facade Systems | Oct 26, 2021

14 projects recognized by DOE for high-performance building envelope design

The inaugural class of DOE’s Better Buildings Building Envelope Campaign includes a medical office building that uses hybrid vacuum-insulated glass and a net-zero concrete-and-timber community center.