In 2002, a couple of years before he died, Charles J. Pankow, Founder and Chairman of design-build firm Charles Pankow Builders, established a research foundation in his name. A pioneer in concrete-forming and moment-framing technology, Pankow was frustrated with the U.S. construction industry’s paltry support of research—a tiny fraction of 1% of revenues, compared to 11.1% of revenue for R&D in the health sector and 4.0% in the automotive, according to PwC’s 2015 Global Innovation 1000 report.

The biggest stumbling block to innovation in construction was (and is) lack of risk capital, due to sub-2% profit margins, says Richard “Rik” Kunnath, PE, Board President of the Charles Pankow Foundation (CPF). Add widespread reluctance among contractors to try anything new, coupled with the fragmentation of the AEC industry, and investing in R&D historically got short shrift.

The CPF wasn’t fettered by those restrictions. “As a nonprofit foundation, we could take risks that others could not,” says Kunnath. In 2006, the foundation started issuing grants, mostly to civil engineering profs at U.S. universities.

Results were mixed. Some of the research did lead to a few code tweaks and design improvements, but there were no breakthroughs. “We were washing the cleanest shirt in the laundry,” Kunnath admits. The foundation needed to concentrate its scarce resources where it could have the greatest impact.

Four years ago, Kunnath and Executive Director Mark J. Perniconi, PE, convened an advisory panel to identify where CPF-sponsored research could have the biggest bang for the buck.

Out of this strategic review came eight R&D initiatives that CPF would focus on (see list at left). It was a rigorous agenda, one that was very much in keeping with Charlie Pankow’s original intent: to cultivate innovation in design and construction and thereby “create buildings of improved quality, efficiency, and value.”

At the same time, the CPF board realized it could not change the AEC world on its own. It needed financial support from others. In recent years, the foundation has partnered with such entities as the ACI Foundation, the American Institute of Steel Construction (AISC), the Construction Industry Institute, the American Society of Concrete Contractors, and AEC firms Clark Construction Group, Magnusson Klemencic Associates, and Skanska USA Building.

Last year, CPF teamed up with 17 co-funders, whose investments leveraged its grant-making capability by 40-50%, says Kunnath. It was CPF’s biggest year ever: more than $2 million in grants. Let’s take a look at a few such efforts.

helping to MAKe INROADS ON BIM INTEROPERABILITY

CPF’s biggest investment—about $4 million—has been in BIM interoperability. “The SEs have their BIM software, the GCs have theirs, and the programs don’t speak to each other,” says Kunnath. CPF is supporting research at Georgia Tech to develop “translator codes” that will let the various BIM programs to talk to each other.

Out of that research came CPF’s Owners’ Guide to BIM Utilization. “It gives owners a good understanding of where BIM works, when to use it, at what level of detail,” says Kunnath. The guide has been adopted by the U.S. Army Corps of Engineers and others.

CPF has also supported BIM-M, a five-year program to encourage BIM use in masonry. It started when members of the Mason Contractors Association of America said they were being asked to bid projects using BIM. “Most had no idea how to do it,” says David Biggs, PE, SE, BIM-M Program Coordinator. “The steel and concrete people were well ahead of us in BIM.”

By the time the program sunsets next year, BIM-M will have invested about $2.2 million in R&D and BIM education for masons. “We’re supporting the development of plug-ins to make existing BIM software from Tekla and other vendors more useful to mason contractors,” says Biggs.

ENABLING STEEL AND CONCRETE R&D

Aiding research to make high-strength steel rebar a reality in the U.S. has been a major initiative. “U.S. codes don’t allow steel above 60 ksi, while the rest of the world is using 100 ksi steel,” says Kunnath. The HSS steel effort will take a decade and cost $10-15 million, but “in the end, we will have moved the U.S. into the modern era to make buildings cheaper and more globally competitive.”

CPF is partnering with AISC on concrete-filled composite plate shear walls. The three-year, $600,000 project (split evenly by CPF and AISC) will generate experimental data and numerical models leading to design guidelines for CF-CPSW core walls.

The research is being headed by Amit Varma at Purdue University. If successful, it would allow such core walls to be erected four stories at a time, using anchors and studs, with no rebar. AISC Vice President Lawrence F. Knuth, PE, says FEMA is adding $150,000 to the pot to test whether CF-CPSW walls could yield an R-value of R-8 for concrete (currently, R-6).

"We needed a new strategy. we were washing the cleanest shirt in the laundry."

Rik kunnath, PE, Charles Pankow Foundation

CPF is not alone in sponsoring AEC-related research. A number of architecture giants—Gensler, Perkins+Will, Perkins Eastman, CallisonRTKL, and GBBN, among others—routinely conduct research related to their work.

The AIA’s Academy for Architecture in Health Foundation has given $200,000 toward research in the last four years, notably for designing improved patient flow in emergency departments.

But the true catalyst for change in the construction sector has been the Charles Pankow Foundation. Since 2006, it has funded more than $12 million in research. The foundation recently pulled together a panel of 10 experts to codify best practices for high-rise construction in earthquake zones.

That initiative resulted in “Guidelines for Performance-based Design of Tall Buildings,” which details a peer-reviewed, rather than prescriptive, path for building in seismic zones.

THERE’S MORE TO COME

The foundation has been partnering with the Concrete Reinforcing Steel Institute on a multi-year project to gain industry consensus on performance specifications for high-strength rebar in seismic applications—data that will be used in modifications to the 2019 version of the ACI 318 building code.

The research is being conducted at multiple universities—Kansas and UT Austin among them—with technical help and materials donations in the $2-4 million range from steel mills and fabs.

“Having the partnership is crucial to getting all this research into practice,” says David McDonald, PhD, PE, FACI, the CRSI’s CEO.

“Research into practice.” That’s what the Charles Pankow Foundation is all about.

Related Stories

AEC Innovators | Mar 3, 2023

Meet BD+C's 2023 AEC Innovators

More than ever, AEC firms and their suppliers are wedding innovation with corporate responsibility. How they are addressing climate change usually gets the headlines. But as the following articles in our AEC Innovators package chronicle, companies are attempting to make an impact as well on the integrity of their supply chains, the reduction of construction waste, and answering calls for more affordable housing and homeless shelters. As often as not, these companies are partnering with municipalities and nonprofit interest groups to help guide their production.

Modular Building | Mar 3, 2023

Pallet Shelter is fighting homelessness, one person and modular pod at a time

Everett, Wash.-based Pallet Inc. helped the City of Burlington, Vt., turn a municipal parking lot into an emergency shelter community, complete with 30 modular “sleeping cabins” for the homeless.

Codes | Mar 2, 2023

Biden Administration’s proposed building materials rules increase domestic requirements

The Biden Administration’s proposal on building materials rules used on federal construction and federally funded state and local buildings would significantly boost the made-in-America mandate. In the past, products could qualify as domestically made if at least 55% of the value of their components were from the U.S.

Industry Research | Mar 2, 2023

Watch: Findings from Gensler's latest workplace survey of 2,000 office workers

Gensler's Janet Pogue McLaurin discusses the findings in the firm's 2022 Workplace Survey, based on responses from more than 2,000 workers in 10 industry sectors.

AEC Innovators | Mar 2, 2023

Turner Construction extends its ESG commitment to thwarting forced labor in its supply chain

Turner Construction joins a growing AEC industry movement, inspired by the Design for Freedom initiative, to eliminate forced labor and child labor from the production and distribution of building products.

Multifamily Housing | Mar 1, 2023

Multifamily construction startup Cassette takes a different approach to modular building

Prefabricated modular design and construction have made notable inroads into such sectors as industrial, residential, hospitality and, more recently, office and healthcare. But Dafna Kaplan thinks that what’s held back the modular building industry from even greater market penetration has been suppliers’ insistence that they do everything: design, manufacture, logistics, land prep, assembly, even onsite construction. Kaplan is CEO and Founder of Cassette, a Los Angeles-based modular building startup.

AEC Innovators | Feb 28, 2023

Meet the 'urban miner' who is rethinking how we deconstruct and reuse buildings

New Horizon Urban Mining, a demolition firm in the Netherlands, has hitched its business model to construction materials recycling. It's plan: deconstruct buildings and infrastructure and sell the building products for reuse in new construction. New Horizon and its Founder Michel Baars have been named 2023 AEC Innovators by Building Design+Construction editors.

Airports | Feb 28, 2023

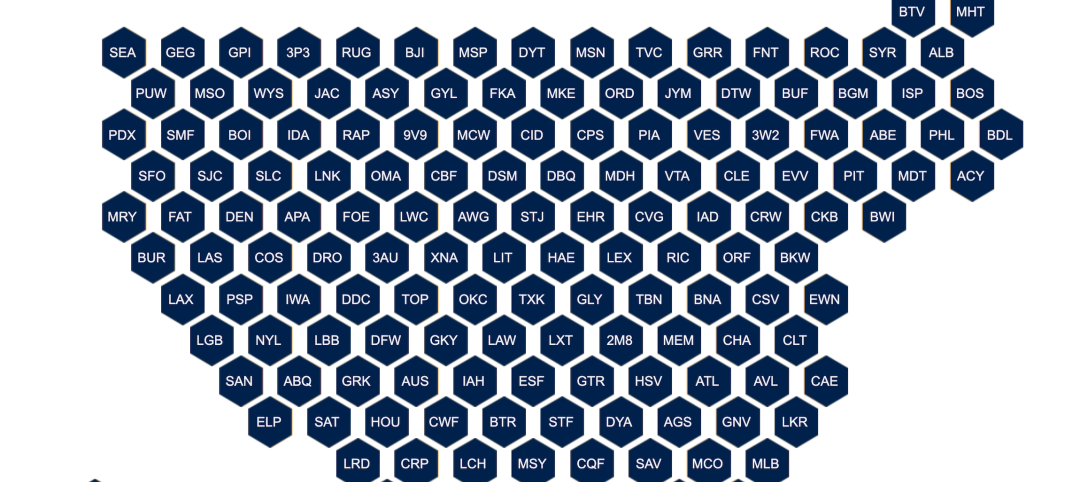

Data visualization: $1 billion earmarked for 2023 airport construction projects

Ninety-nine airports across 47 states and two territories are set to share nearly $1 billion in funding in 2023 from the Federal Aviation Administration. The funding is aimed at help airports of all sizes meet growing air travel demand, with upgrades like larger security checkpoints and more reliable and faster baggage systems.

Seismic Design | Feb 27, 2023

Turkey earthquakes provide lessons for California

Two recent deadly earthquakes in Turkey and Syria offer lessons regarding construction practices and codes for California. Lax building standards were blamed for much of the devastation, including well over 35,000 dead and countless building collapses.

Sports and Recreational Facilities | Feb 27, 2023

New 20,000-seat soccer stadium will anchor neighborhood development in Indianapolis

A new 20,000-seat soccer stadium for United Soccer League’s Indy Eleven will be the centerpiece of a major neighborhood development in Indianapolis. The development will transform the southwest quadrant of downtown Indianapolis by adding more than 600 apartments, 205,000 sf of office space, 197,000 sf for retail space and restaurants, parking garages, a hotel, and public plazas with green space.