A 2013 analysis of two-dimensional elevator traffic systems likens the present use of one cabin per elevator shaft to using an entire railway line between two sites with a single train—an avoidable inefficiency.

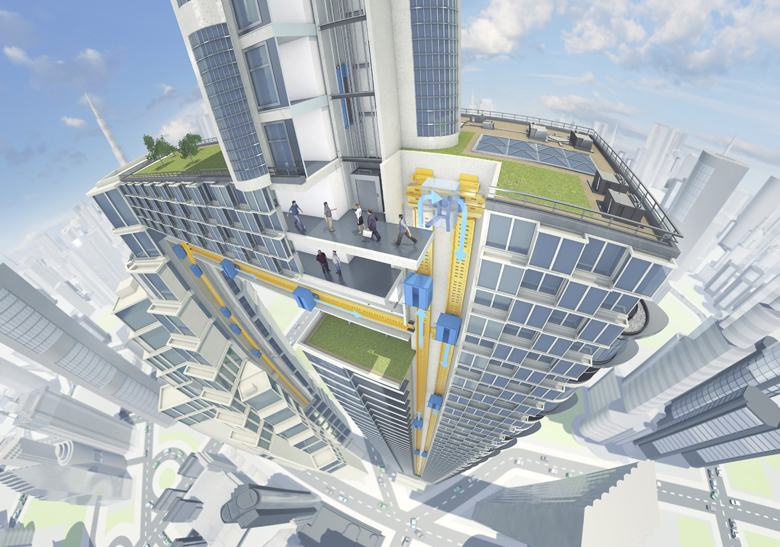

ThyssenKrupp's latest offering, named MULTI, will allow several cabins in the same shaft to move vertically and horizontally, which the company says is “a new and efficient transport solution for mid- and high-rise buildings.”

The mechanism is made possible by applying the linear motor technology of the magnetic levitation train Transrapid to the elevator industry.

In a manner similar to a metro system operation, the elevator design can incorporate various self-propelled elevator cabins per shaft running in a loop, increasing the shaft transport capacity by up to 50%, making it possible to reduce the elevator footprint in buildings by as much as 50%.

The elevator requires no cables, and uses a multi-level brake system and inductive power transfers between shaft and cabin. This allows the elevator to occupy smaller shafts than conventional elevators, which can increase a building's usable area by up to 25%. The overall increase in efficiency also translates into a lower requirement for escalators and additional elevator shafts, resulting in significant construction cost savings as well as a multiplication of rent revenues from increased usable space.

Although the ideal building height for MULTI installations starts at 300 meters, this system is not constrained by a building's height.

“Building design will no longer be limited by the height or vertical alignment of elevator shafts, opening possibilities to architects and building developers they have never imagined possible,” the company said in a release.

MULTI is based on the concept of ThyssenKrupp TWIN's control system and safety features, but includes new features such as new and lightweight materials for cabins and doors, resulting in a 50% weight reduction as compared to standard elevators, as well as a new linear drive—using one motor for horizontal and vertical movements.

Operating on the basic premise of a circular system, such as a paternoster, MULTI consists of various cabins running in a loop at a targeted speed of 16 m/s, enabling passengers to have near-constant access to an elevator cabin every 15 to 30 seconds, with a transfer stop every 50 meters.