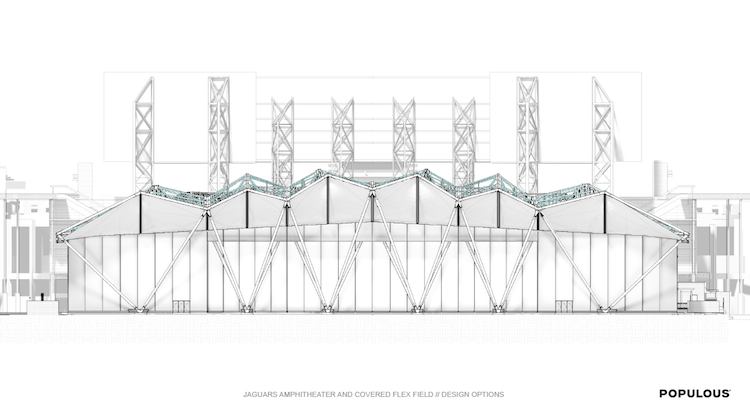

Inspired by the city’s mesmerizing network of estuaries and bridges that span the St. Johns River and frame the NFL Jacksonville Jaguars’ home facility, Daily’s Place, the Jaguars’ new 6,000-seat amphitheater and 94,000-sf indoor practice field, owes its identity to a local convenience store chain that won the naming rights.

There was nothing convenient about the amphitheater’s design, however. The 160,000-sf structure is a deceptively complex building, marked by its most intricate feature, an undulating roof. Hundreds of AEC professionals scattered around the world employed a dazzling array of 3D and 4D software programs to create and build this signature design element.

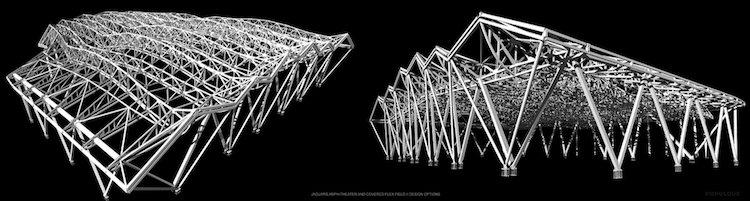

The roof consists of 3,000 tons of structural steel that support a PTFE membrane. The PTFE fabric is suspended from 430-foot-long structural steel trusses that sit atop an array of structural steel v-columns. The roof links the steel beams with the PTFE membrane, which was placed on the underside of the structure—something that had never been done before.

According to Populous, this was done to keep the continuity of the building’s architecture in relation to Jacksonville’s bridges visible from the exterior. Since right angles are rare in nature and just about nonexistent when it comes to rivers, the roof—in fact, the entire structure—was designed such that it does not have a single piece of steel perpendicular to another.

Creating and implementing this riverine design was premeditated, calculated, and engineered to come together exactly the way it did. But without the use of software like Grasshopper, Rhino, and Revit, there is no way the roof could have been completed in five months, as it was.

Grasshopper was used to review the design of the structure and calculate the reductions in roof fabric that were needed to suck in the roof from the sides and reduce overhangs. Grasshopper also helped to rectify a delay in the rolled steel schedule by allowing the team to easily determine which members provided a stronger impact between rolled versus straight members.

The workflow of Rhino to Revit helped the team to discover that the roof geometry needed to be corrected at the intersection of the roof and the concourse. This workflow allowed the build team to locate the intersection early on and correct the geometry before construction advanced too far, saving time and money.

Hundreds of professionals from firms across the U.S. (Kansas City, Los Angeles, New York, and Jacksonville), England, and New Zealand participated in the project. To avoid time-wasting errors, Populous maximized its 3D model and available software to create a model that could be shared by the contractor, steel fabricator, and erector.

Populous and structural engineer and design team member Walter P Moore knew from the outset that “an embedded and nontraditional design and documentation strategy was needed to be able to deliver the complex project in the 12-month construction schedule,” says Thom Chuparkoff, AIA, LEED AP, Lead Project Manager for Populous.

Populous and Walter P Moore implemented, shared, and tested Grasshopper, Dynamo, and Revit concurrently throughout the entire project. This process allowed the design to be automated and iterative to meet the construction managers’ needs and the subcontractors’ schedules.

As the project advanced, the Grasshopper and Revit models were transferred into Tekla software, which allowed for collaboration between the design and construction teams. Populous, Walter P Moore, Hunt Construction Group, Danis Building Construction, Banker Steel, and Structurflex were able to use the same design and fabrication models concurrently to advance the design and detailing for construction.

“Walter P Moore and Populous took responsibility for the Tekla model to create the Advanced Bill of Materials model, which they turned over to Banker Steel for fabrication and assembly,” says Chuparkoff. Banker Steel was then able to use Walter P Moore to utilize their own models for the shop drawing portion. This saved time in fabrication and installation.

In the construction realm, the workflows allowed the design and construction process to become blurred. “By implementing Rhino to Revit early between the architect and structural engineer, we were able to continue that model relationship and extend the workflow into the steel fabrication and detailing,” says Chuparkoff.

Despite the sheer complexity of the structure, the RFI log amounted to less than 300 project-related questions from the field, he says. The multitude of software programs used managed to keep the project organized, updated, and distributed among all team members, regardless of where in the world they were located.

Daily’s Place held its first event May 27. Hometown band Tedeschi Trucks played the first concert in the new amphitheater, which Jaguars owner Shadhid Khan described as “iconic.”

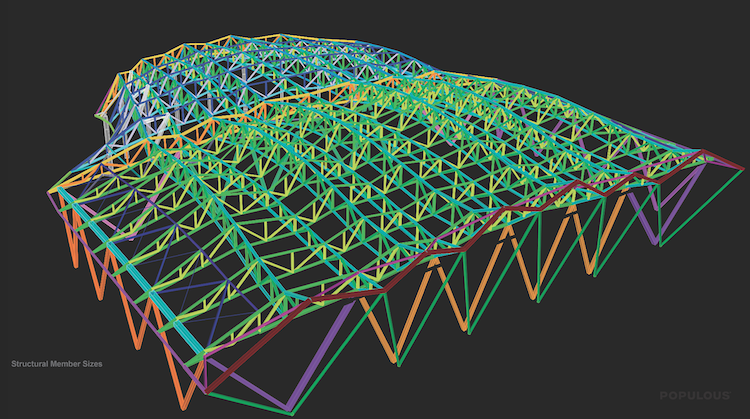

Grasshopper for Rhino was used with the Lunchbox plug-in to create Daily’s Place’s roof structure.

Grasshopper for Rhino was used with the Lunchbox plug-in to create Daily’s Place’s roof structure.

Software helps demystify the project’s complexity

Here’s how the software programs used in Daily’s Place helped simplify the intricate project:

Rhino and Revit were used as the primary geometry modeling programs for the project. The roof and skin were modeled in Rhino, which is considered more dynamic for complex geometry. Rhino was also the common medium for collating digital models and coordinating between teams for interfacing and clash detection of fabric and steel. It was also used for studies of ponding and drainage of the fabric surface. Revit was used for all other geometries and full construction documents.

Grasshopper for Rhino was used in tandem with the Lunchbox plug-in to build the roof surface and subdivide the structure into trusses. The roof form was designed by Populous; then the Grasshopper script was worked on jointly with Walter P Moore to create the structure for the roof.

A Grasshopper script was used to write out point data to an Excel file to transfer geometry from Rhino to Revit for coordination and documentation. Then Dynamo was used to pull that data into Revit to build native geometry with adaptive components. As Walter P Moore was engineering the structure, Populous used this workflow to represent the structure in the Revit model and drawings.

Kangaroo, a form-finding plug-in for Rhino-Grasshopper, was used in the early stages of the job to quickly study design intent. The structure could be updated as programmatic and functional directives changed the roof form. The base input for the script was 13 input curves that could be manually adjusted in Rhino.

The structural analysis components of GSA and SAP software were used in tandem to study structural steel and fabric. These programs helped analyze the structural steel framing through custom-developed plug-ins developed by Walter P Moore that used Grasshopper as the primary interface.

Tekla was used to communicate the full steel package and connection details with the steel contractor via the 3D model. This enabled the seamless transition from CDs to shop drawings and fabrication.

Each piece of steel was modeled and placed with purpose in order to create a design that resembled Jacksonville’s numerous bridges and estuaries. The result is a building without a single piece of steel perpendicular to another.

Each piece of steel was modeled and placed with purpose in order to create a design that resembled Jacksonville’s numerous bridges and estuaries. The result is a building without a single piece of steel perpendicular to another.

Related Stories

AEC Tech | Apr 17, 2019

4 fundamental relationships between buildings and machines

If and when AI drives the entire process of design, construction, and operation, buildings could become exponentially smarter with resources, money, time, and performance.

AEC Tech | Apr 12, 2019

NBBJ creates Design Performance Group whose goal is to connect building design with occupant wellbeing

The firm also wants to advance energy efficiency in its projects.

AEC Tech | Apr 10, 2019

Speaker Update! Accelerate AEC Innovation Conference, May 13-14, NYC

BD+C's third-annual Accelerate AEC Innovation Conference (May 13-14, NYC) will explore AI in architecture, offsite construction, smart buildings, AEC business innovations, big data in construction, and much more.

AEC Tech | Mar 26, 2019

Embracing collaboration tools from outside the AEC industry

Let's take a look at the available technologies from outside AEC that are seeing greater adoption within the industry.

AEC Tech | Mar 24, 2019

5 ways designers and builders can use business intelligence with data they already have

Tricky construction budgets, large project teams, and unique designs needing extensive coordination are all problems increasingly being handled with new software tools and data.

AEC Tech | Feb 8, 2019

BI(m): BIM data without models

A new breed of data tools creates a valuable opportunity for the next wave of BIM and facilities management, one where “pure data” is at the center, writes John Tobin of SMRT Architects.

AEC Tech | Jan 9, 2019

Our robotic future: Assessing AI's impact on the AEC profession and the built environment

This is the first in a series by Lance Hosey, FAIA, on how automation is disrupting design and construction.

3D Printing | Dec 7, 2018

Additive manufacturing heads to the jobsite

Prototype mobile 3D printing shop aims to identify additive manufacturing applications for construction jobsites.

AEC Tech | Sep 27, 2018

BD+C editors want your input on AEC technology

Please help us improve our editorial coverage by taking this brief survey.

Sponsored | AEC Tech | Sep 14, 2018

Sponsored webinar: Benefits of traceable construction

In this free 60-minute webinar, Keith Alcorn of FARO Technologies will talk about the concept of traceable construction and how 3D reality capture solutions provide portable, efficient, secure, and forward-looking solutions for data collection, pre-processing, and evaluation in the design, build and operating phase. September 18, 2:00 EST.