A recent survey of AEC firms and real estate owners and developers found a strong majority that had deployed off-site construction in the previous 12 months and planned to utilize it to a greater extent going forward.

The Off-Site Construction Council of the National Institute of Building Sciences in Washington, D.C. conducted its 2018 Off-Site Construction Industry Survey as a follow-up to a 2014 survey to gauge the industry’s interest in off-site construction, which it defines as the planning, design, fabrication, and assembly of building elements at a location other than their final point of assembly onsite.

Ryan Smith of Washington State University and Kambaja Tarr of the University of Utah conducted and compiled the latest survey for NIBS.

“With the ongoing shortage of skilled craft workers (which exceeded two million in 2017), prefabrication in a controlled, off-site environment may become a necessity for many U.S. contractors attempting to remain competitive with a lower-skilled workforce,” the survey states. But as with any new process or technology innovation, and despite growing demand, ”uncertainties accompany the utilization of off-site construction.”

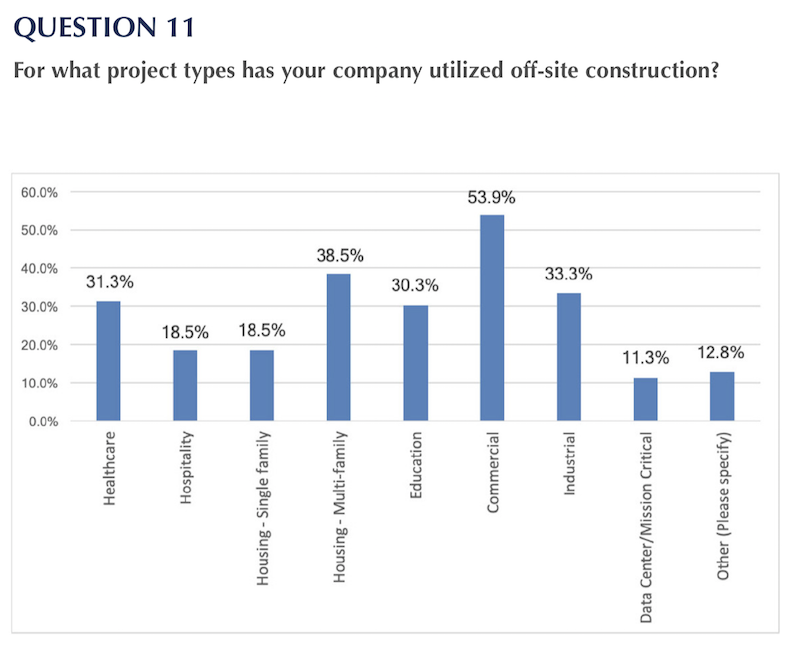

The commercial, multifamily and healthcare sectors are where off-site construction has been finding its greatest demand. Image: NIBS

A total of 205 participants responded to the 2018 Off-Site Construction Industry survey, versus 312 respondents to the 2014 poll. The participating companies provide a variety of different services, including construction management/general contracting (24.75% in 2018; 46.7% in 2014), engineering (21.72% and 38.3%), trade contracting (2.53% and 27.3%), architecture (87.88% and 15%), and owners/developers (10.1% and 8.3%).

Nearly nine of 10 respondents to the 2018 survey (87.72%) had used off-site fabricated components to some degree over the previous 12 months, and more than eight in 10 (81.63%) expected to engage off-site construction more often or the same amount in the following 12 months. (Both percentages were down slightly from the 2014 survey.)

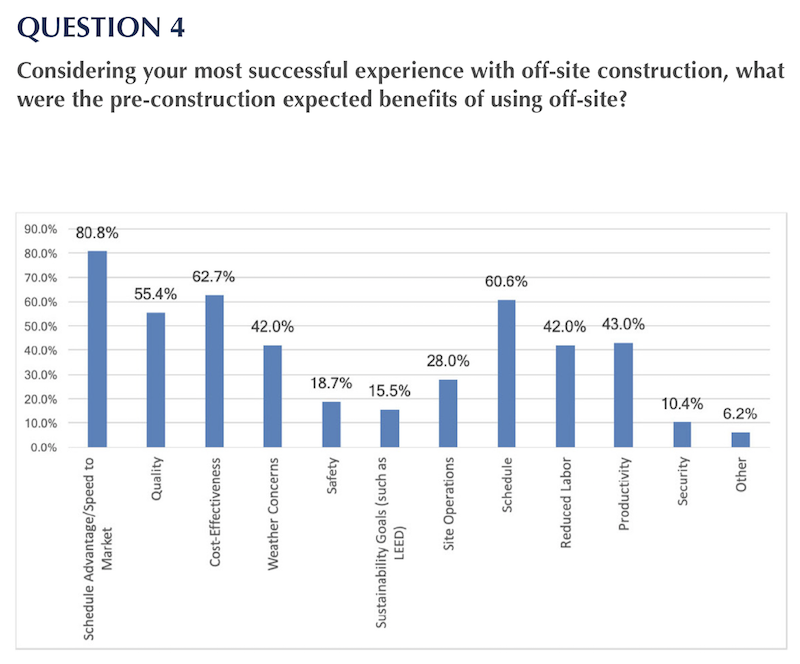

The primary benefit identified in both surveys is a reduced overall project schedule, specifically the duration of the construction phase.

For more than three fifths of respondents (63.22%) designers, architects and engineers were the primary decision makers about when off-site construction is implemented, followed by construction managers or general contractors (47.67%), clients (41.97%), and others, primarily subcontractors (21.24%).

Keeping projects on schedule is where companies that deploy off-site construction have been seeing the greatest benefit. Image: NIBS

Interestingly, however, respondents stated that the most significant barrier to off-site construction is the culture of design and construction in general. Comments indicated that late design changes, lack of collaboration and an adversarial climate for project delivery leads to difficulties in realizing the benefits of off-site construction.

The survey notes that the building component fabrication industry is still maturing and needs more time to integrate effectively with site-built work. In addition, contractors are still learning how to manage off-site products for assembly on-site.

Transportation is another significant barrier: specifically, how far away a factory is located from the construction site.

Respondents in both surveys qualitatively noted that some projects, particularly those with long spans, may not be suited for the use of pre-fabricated elements, and that each project has unique requirements that must be met through an appropriate technical solution.

Related Stories

Cultural Facilities | Jun 10, 2022

After 10 Years, Taiwan’s new Taipei Music Center Reaches the Finish Line

RUR Architecture has finished the Taipei Music Center (TMC), turning a 22-acre (9-hectare) site into a new urban arts district.

Building Technology | Jun 9, 2022

GSA Green Proving Ground program selects six innovative building technologies for evaluation

The U.S. General Services Administration’s (GSA) Green Proving Ground program, in collaboration with the U.S. Department of Energy, has selected six innovative building technologies for evaluation in GSA’s inventory.

University Buildings | Jun 9, 2022

IDEA Factory at U. of Maryland defies gravity

The E.A. Fernandez IDEA Factory at the University of Maryland’s A. James Clark School of Engineering has a gravity-defying form: The seven-story building’s solid upper floors emerge above the lighter, mostly glass base.

Multifamily Housing | Jun 9, 2022

Cityview's Adam Perry on multifamily housing innovation in the Western U.S.

Adam Perry, SVP of Development and Construction Management with developer Cityview, chats with Multifamily Design+Construction Editor Rob Cassidy about the latest design and construction innovations for multifamily housing in the West.

Libraries | Jun 8, 2022

Welcome to the hybrid library

Libraries have grown to become the intellectual and social hubs of campus, where, prior to March 2020, students, researchers, and faculty gathered to collaborate and connect.

Building Team | Jun 8, 2022

Alastair MacGregor to lead WSP USA Property and Buildings Business

Alastair (Aly) MacGregor has been named the executive business line leader for Property and Buildings at WSP USA, one of the nation’s largest engineering and professional services consultancies.

Codes and Standards | Jun 8, 2022

Florida Legislature passes bill requiring stricter condominium inspection

The Florida Legislature recently passed a bill to beef up building inspection requirements for many of the state’s condominiums.

Office Buildings | Jun 8, 2022

Former L.A. Times newsroom/printing plant remade into office campus

Phase 1 of The Press, an adaptive reuse project that is converting an old Los Angeles Times facility into a modern office campus, was recently completed in Costa Mesa, Calif.

Codes and Standards | Jun 7, 2022

FEMA launches National Initiative to Advance Building Codes

The U.S. Federal Emergency Management Agency (FEMA) has launched a new government-wide effort to boost national resiliency and reduce energy costs.

Plumbing | Jun 7, 2022

Sloan launches ‘Sinks Beyond the Restroom’ innovation

Sloan, the world’s leading manufacturer of commercial plumbing systems, has launched its ‘Sinks Beyond the Restroom’ concept.