A recent survey of AEC firms and real estate owners and developers found a strong majority that had deployed off-site construction in the previous 12 months and planned to utilize it to a greater extent going forward.

The Off-Site Construction Council of the National Institute of Building Sciences in Washington, D.C. conducted its 2018 Off-Site Construction Industry Survey as a follow-up to a 2014 survey to gauge the industry’s interest in off-site construction, which it defines as the planning, design, fabrication, and assembly of building elements at a location other than their final point of assembly onsite.

Ryan Smith of Washington State University and Kambaja Tarr of the University of Utah conducted and compiled the latest survey for NIBS.

“With the ongoing shortage of skilled craft workers (which exceeded two million in 2017), prefabrication in a controlled, off-site environment may become a necessity for many U.S. contractors attempting to remain competitive with a lower-skilled workforce,” the survey states. But as with any new process or technology innovation, and despite growing demand, ”uncertainties accompany the utilization of off-site construction.”

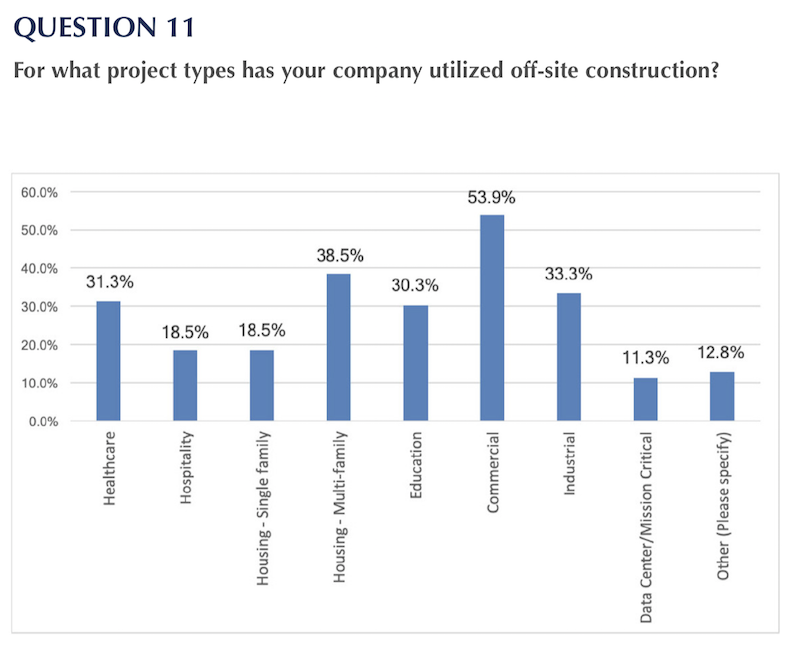

The commercial, multifamily and healthcare sectors are where off-site construction has been finding its greatest demand. Image: NIBS

A total of 205 participants responded to the 2018 Off-Site Construction Industry survey, versus 312 respondents to the 2014 poll. The participating companies provide a variety of different services, including construction management/general contracting (24.75% in 2018; 46.7% in 2014), engineering (21.72% and 38.3%), trade contracting (2.53% and 27.3%), architecture (87.88% and 15%), and owners/developers (10.1% and 8.3%).

Nearly nine of 10 respondents to the 2018 survey (87.72%) had used off-site fabricated components to some degree over the previous 12 months, and more than eight in 10 (81.63%) expected to engage off-site construction more often or the same amount in the following 12 months. (Both percentages were down slightly from the 2014 survey.)

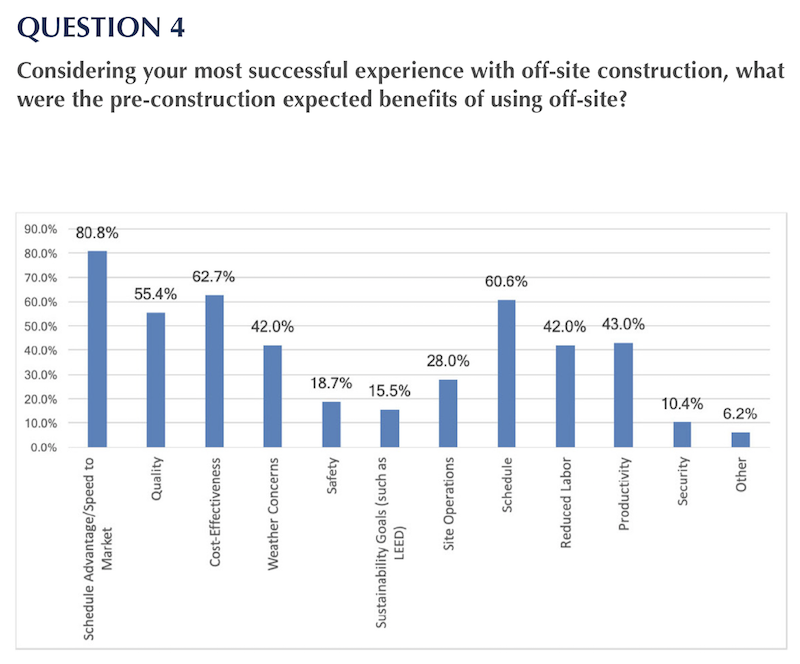

The primary benefit identified in both surveys is a reduced overall project schedule, specifically the duration of the construction phase.

For more than three fifths of respondents (63.22%) designers, architects and engineers were the primary decision makers about when off-site construction is implemented, followed by construction managers or general contractors (47.67%), clients (41.97%), and others, primarily subcontractors (21.24%).

Keeping projects on schedule is where companies that deploy off-site construction have been seeing the greatest benefit. Image: NIBS

Interestingly, however, respondents stated that the most significant barrier to off-site construction is the culture of design and construction in general. Comments indicated that late design changes, lack of collaboration and an adversarial climate for project delivery leads to difficulties in realizing the benefits of off-site construction.

The survey notes that the building component fabrication industry is still maturing and needs more time to integrate effectively with site-built work. In addition, contractors are still learning how to manage off-site products for assembly on-site.

Transportation is another significant barrier: specifically, how far away a factory is located from the construction site.

Respondents in both surveys qualitatively noted that some projects, particularly those with long spans, may not be suited for the use of pre-fabricated elements, and that each project has unique requirements that must be met through an appropriate technical solution.

Related Stories

Market Data | Jun 15, 2022

ABC’s construction backlog rises in May; contractor confidence falters

Associated Builders and Contractors reports today that its Construction Backlog Indicator increased to nine months in May from 8.8 months in April, according to an ABC member survey conducted May 17 to June 3. The reading is up one month from May 2021.

Codes and Standards | Jun 15, 2022

Waived tariffs on solar panels expected to boost solar power

The Biden Administration recently waived tariffs on solar panels from four countries in a move advocates say will accelerate the clean energy transition and benefit national security.

Cultural Facilities | Jun 15, 2022

Gehry-designed Children’s Institute aims to foster community outreach in L.A.’s Watts neighborhood

The Children’s Institute (CII) in Los Angeles will open a 200,000-sf campus designed by Frank Gehry this summer.

Building Team | Jun 14, 2022

Thinking beyond the stadium: the future of district development

Traditional sports and entertainment venues are fading as teams and entertainment entities strive to move toward more diversified entertainment districts.

Codes and Standards | Jun 14, 2022

Hospitals’ fossil fuel use trending downward, but electricity use isn’t declining as much

The 2021 Hospital Energy and Water Benchmarking Survey by Grumman|Butkus Associates found that U.S. hospitals’ use of fossil fuels is declining since the inception of the annual survey 25 years ago, but electricity use is dipping more slowly.

Healthcare Facilities | Jun 13, 2022

University of Kansas Health System cancer care floors foster community and empathy

On three floors of Cambridge Tower A at The University of Kansas Health System in Kansas City, patients being treated for blood cancers have a dedicated space that not only keeps them safe during immune system comprising treatments, but also provide feelings of comfort and compassion.

Building Team | Jun 13, 2022

Ware Malcomb promotes Matt Chaiken to vice president

Ware Malcomb, an award-winning international design firm, today announced that Matt Chaiken has been promoted to Vice President in the firm’s Denver office.

Building Team | Jun 13, 2022

Partnership rethinks emergency shelters to turn them into sustainable, resilient homes

Holcim and the Norman Foster Foundation have struck a partnership to rethink emergency shelters to turn them into sustainable and resilient homes.

Building Team | Jun 13, 2022

A mixed-used building to rise above Fort Lauderdale, with views of downtown and the ocean

ODA, a New York-based architecture and design studio, recently released renderings of Ombelle, a project including two residential towers in Fort Lauderdale, Fla.

Office Buildings | Jun 13, 2022

San Antonio’s electric utility HQ to transform into a modern office building

In San Antonio, Tex., the former headquarters of CPS Energy, the city’s electric utility, is slated to transform into 100,000 square feet of office and retail space on San Antonio’s famed River Walk.