McKinsey & Company, the international corporate consulting firm, has issued a new research study, “Modular construction: From projects to products.” Written by an international team, it discusses a wide range of building sectors, but its main focus is multifamily.

The authors claim that modular construction could claim $45 billion of the total $277 billion new-build multifamily market by 2030 in the U.S. and Europe at moderate penetration and save $6 billion a year in costs.

Assuming the U.S. represents at least half of the market (probably more like 60-70%), those would seem to be very attractive numbers for apartment, student housing, and senior living construction, where modular construction works best.

SEE ALSO: Almost everything you wanted to know about industrial construction

But I have some problems with the McKinsey findings. To start with, I wonder where they got the $277 billion figure for multifamily construction in the U.S. and Europe by 2030. That looks really high to me. It would be a godsend if the U.S. could be producing half of that, say, $130 billion or more of apartments and other forms of multifamily—we sure could use them. But with the U.S. producing at best $60-70 billion in multifamily construction, it’s hard to see a doubling of that rate of construction in the next decade.

The McKinsey numbers may also be weighted toward the rest of the world, less so toward the U.S. One of the charts I found most intriguing (page 22 of the report, if you’re keeping score) had to do with the current offsite share of housing by country, i.e., how much “factory-produced” housing construction is going on in various countries.

The global leader turns out to be the trifecta of Finland-Norway-Sweden, where 45% of housing construction is produced off site, followed by Japan (15%), Germany (10%), China (6%), and Australia and the U.K. (each 5%). The U.S.? Three percent.

It’s not all doom and gloom for the U.S. Modular, prefab, or “industrial construction” is starting to catch on, particularly in student housing and the low- to mid-rise apartment sector. One reason for this is the pervasive adoption of Revit and other 3D modeling tools, which make it relatively easy to transfer data from the designer’s desktop directly to the offsite factory.

Another reason why we’ll see more industrial construction in multifamily is the dire shortage of skilled labor. As the McKinsey experts note, shifting to offsite manufacture is cheaper—and “it may even attract new people into the workforce who do not wish to move from one construction site to another following projects.” Or who’d rather be in a nice cozy factory than freezing their butts on a job site in the middle of a Minnesota winter.

But don’t expect huge savings in initial costs. The most important benefit of offsite construction, when done right, is reliability—the assurance that a wall system or an entire room module can and will be delivered on time and to high level of specification.

Related Stories

| Dec 31, 2013

BD+C's top 10 stories of 2013

The world's tallest twisting tower and the rise of augmented reality technology in construction were among the 10 most popular articles posted on Building Design+Construction's website, BDCnetwork.com.

| Dec 27, 2013

$1 billion 'city within a city' development approved by Coachella, Calif., city council

The mega development includes 7,800 homes, a retail center, office space, and nearly 350 acres of open space.

| Dec 23, 2013

MBI commends start of module setting at B2, world's tallest modular building

The first modules have been set at B2 residential tower at Atlantic Yards in New York, set to become the tallest modular building in the world.

| Dec 20, 2013

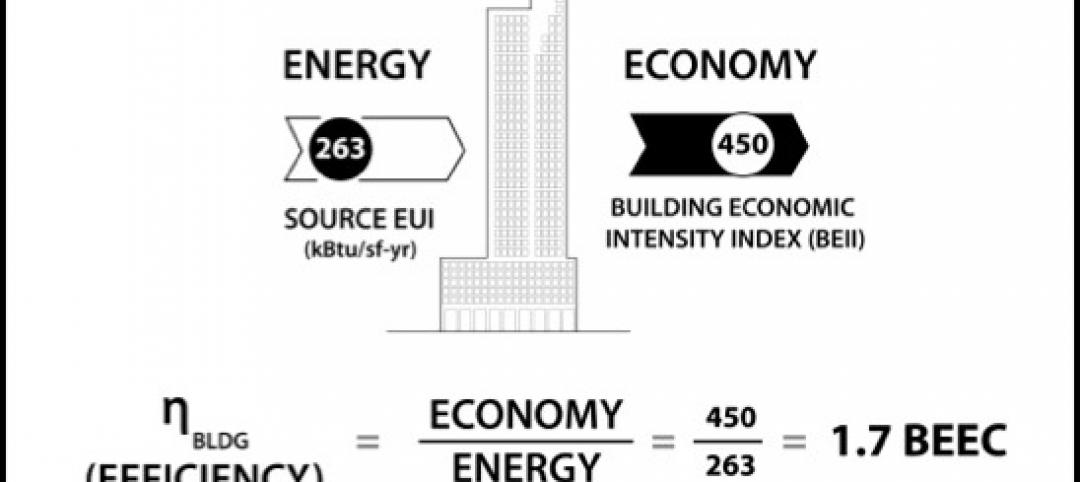

Can energy hogs still be considered efficient buildings? Yes, say engineers at Buro Happold

A new tool from the engineering firm Buro Happold takes into account both energy and economic performance of buildings for a true measure of efficiency.

| Dec 13, 2013

Safe and sound: 10 solutions for fire and life safety

From a dual fire-CO detector to an aspiration-sensing fire alarm, BD+C editors present a roundup of new fire and life safety products and technologies.

| Dec 10, 2013

16 great solutions for architects, engineers, and contractors

From a crowd-funded smart shovel to a why-didn’t-someone-do-this-sooner scheme for managing traffic in public restrooms, these ideas are noteworthy for creative problem-solving. Here are some of the most intriguing innovations the BD+C community has brought to our attention this year.

| Dec 4, 2013

First look: Dubai's winning bid for World Expo 2020 [slideshow]

Dubai has been chosen as the site of the 2020 World Expo. HOK led the design team that developed the master plan for the Expo, which is expected to draw more than 25 million visitors from October 2020 through April 2021.

| Nov 27, 2013

Exclusive survey: Revenues increased at nearly half of AEC firms in 2013

Forty-six percent of the respondents to an exclusive BD+C survey of AEC professionals reported that revenues had increased this year compared to 2012, with another 24.2% saying cash flow had stayed the same.

| Nov 27, 2013

Wonder walls: 13 choices for the building envelope

BD+C editors present a roundup of the latest technologies and applications in exterior wall systems, from a tapered metal wall installation in Oklahoma to a textured precast concrete solution in North Carolina.

| Nov 26, 2013

Construction costs rise for 22nd straight month in November

Construction costs in North America rose for the 22nd consecutive month in November as labor costs continued to increase, amid growing industry concern over the tight availability of skilled workers.