|

| The solar shade of the Art Institute of Chicago’s Modern Wing was designed to collect and redirect natural light from the north and filter out intense southern light. |

Italian architect Renzo Piano refers to his $294 million, 264,000-sf Modern Wing of the Art Institute of Chicago as a “temple of light.” That's all well and good, but how did Piano and the engineers from London-based Arup create an almost entirely naturally lit interior while still protecting the priceless works of art in the Institute's third-floor galleries from dangerous ultraviolet rays?

Piano addressed that concern by hanging a 216-foot-wide “flying carpet” canopy over the glazed roof of the Modern Wing's east building to filter light and eliminate the threat to the art. This sunshield, supported by steel bracings above the museum's third-floor galleries, is composed of thousands of extruded aluminum “blades” precisely angled to collect and redirect natural light from the north and filter out the dangerous and more intense southern light. Additional screening and computer-adjusted electrical lighting achieve the ideal combination of appropriate lighting, reduced electrical expenses, and art preservation. All of this contributed to the Modern Wing, which opened last May, achieving LEED Silver certification.

“This is made easier in a city that is built on precise north-south and east-west axes, perfectly in tune with the cycle of the sun, like a solar machine,” Piano wrote in notes to his original Modern Wing drawings.

|

| The sprawling sunshade also shields patrons from the sun on the Art Institute’s third-floor, 3,400-sf viewing deck that leads to a bridge to nearby Millennium Park, seen here from the viewing deck. The bridge was also designed by Renzo Piano. |

Robert Lang, lead structural engineer on the project, has been with Arup for 27 years and has spent 20 of those years working with Piano on his projects. He's worked on similar shading and screening devices for Piano's designs of the Los Angeles County Museum of Art, the Lingotto Factory Conversion in Turin, Italy, and the Beyeler Foundation near Basel, Switzerland.

The blades are roughly 13-and-a-half feet long and are situated very crudely at an angle of 45 degrees, says Lang. “They are sculpted and shaped so that they're structurally stable,” he says. “At the low end they're open to the north to allow the indirect northern light in. At the east and west ends they have a series of fins attached to them to catch and block southern light.”

There are more than two thousand small blades on the 46,600-sf “flying carpet,” each supported at two anchor points. The blades were computer-modeled by Arup for maximum energy efficiency and custom fabricated by Sapa RC Profiles in Belgium, which shipped each blade to the site ready for installation. Inside the Modern Wing, a finely calibrated dimming system uses photocells to adjust the supplied lighting to fluctuations in daylighting levels according to time of day, season, and weather. The ceiling and roof of the Modern Wing have two layers of glass and two separate shading systems.

|

| This sketch by architect Renzo Piano shows how building orientation was used to gather and take advantage of northern light at the Art Institute. |

All of Piano's shading devices share common elements from project to project, but the Art Institute's solar shade had to be specially reinforced to withstand changing temperatures and winds of the city's lakefront. “The climate in Chicago, being as severe as it is, was a concern,” says Lang. “For the force of wind, the blades were designed to withstand movement due to high wind by heavy anchoring in the two positions they were affixed to.” Horizontal directional movement was less than 1.1 inches.

“When it comes to temperature fluctuation, we basically allowed the shade structure to expand and contract due to temperature, always away from the center,” says Lang. “The ends of the roof need to be quite large, and the steelwork was anchored to the support polls and outer walls, one solidly, the other less solidly, to allow for expansion and contraction.”

Each of Piano's Modern Wing flying carpet canopies extends its edge panels out past the last supporting side of the building below to increase the sense of lightness, so the solar shade appears to dissolve at its endpoint. Each roof beam supporting the Art Institute's flying carpet was fabricated offsite and sent to the site as a single piece to be installed.

|

| This photo of the ceiling of the East Building, taken during construction, shows the rooftop blades without interior shades below the glass roof. |

Inside each beam is a prestressed steel joint that was joined onsite to the lower structure or another beam. Each beam had to be installed in sequence, as the beams make up a web of tolerances that all depend on one another. The intricate web spun by Piano created the desired look of openness and weightlessness.

“I think the story we are telling with the new addition is about accessibility,” Piano wrote in his notes about the addition. “It's about openness. It's about a building that should not be intimidating.”

Related Stories

| Mar 7, 2014

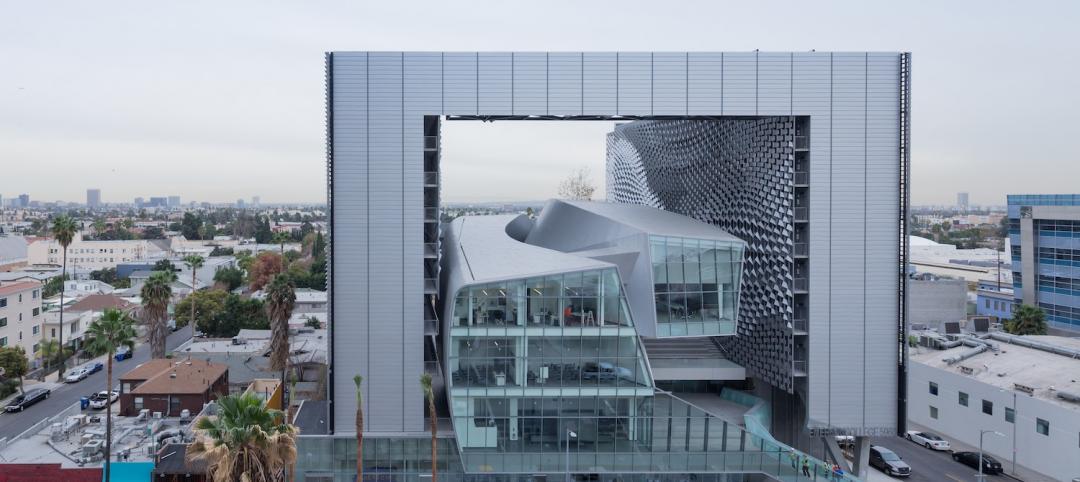

Thom Mayne's high-tech Emerson College LA campus opens in Hollywood [slideshow]

The $85 million, 10-story vertical campus takes the shape of a massive, shimmering aircraft hangar, housing a sculptural, glass-and-aluminum base building.

| Mar 4, 2014

How EIFS came to America

Design experts from Hoffmann Architects offer a brief history of exterior insulation and finish systems in the U.S.

| Feb 19, 2014

AIA class: The ABCs of IMPs – How to design and build with insulated metal panels

This AIA/CES class offers insight in areas including policies and codes surrounding insulated metal panels, contributions from LEED and tax credits, energy modeling, and business development opportunities available with IMPs. Take this course and earn 1.0 AIA LU/HSW/SD.

| Feb 5, 2014

CENTRIA Redefines Coating System with Versacor® Elite

The Versacor Elite Coating System is a premium metal coating system that provides the highest level of protection in the harshest climatic or environmental conditions.

| Jan 28, 2014

White Paper: How metal buildings deliver long-term value to schools

A new white paper from Star Building Systems outlines the benefits of metal buildings for public and private school building projects.

| Jan 28, 2014

2014 predictions for skyscraper construction: More twisting towers, mega-tall projects, and 'superslim' designs

Experts from the Council on Tall Buildings and Urban Habitat release their 2014 construction forecast for the worldwide high-rise industry.

| Jan 23, 2014

Adrian Smith + Gordon Gill-designed Federation of Korean Industries tower opens in Seoul [slideshow]

The 50-story tower features a unique, angled building-integrated photovoltaic (BIPV) exterior designed to maximize the amount of energy collected.

| Jan 13, 2014

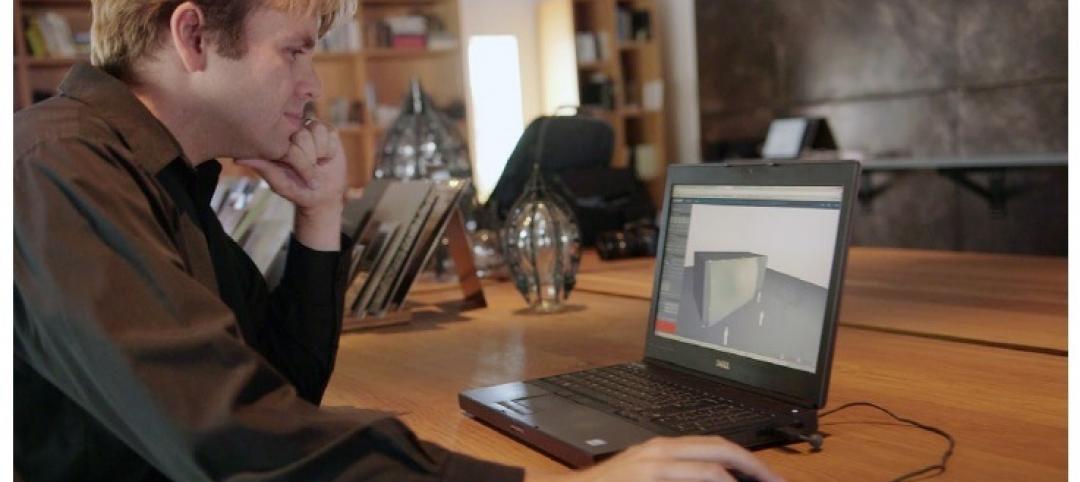

Custom exterior fabricator A. Zahner unveils free façade design software for architects

The web-based tool uses the company's factory floor like "a massive rapid prototype machine,” allowing designers to manipulate designs on the fly based on cost and other factors, according to CEO/President Bill Zahner.

| Dec 10, 2013

16 great solutions for architects, engineers, and contractors

From a crowd-funded smart shovel to a why-didn’t-someone-do-this-sooner scheme for managing traffic in public restrooms, these ideas are noteworthy for creative problem-solving. Here are some of the most intriguing innovations the BD+C community has brought to our attention this year.

| Nov 27, 2013

Wonder walls: 13 choices for the building envelope

BD+C editors present a roundup of the latest technologies and applications in exterior wall systems, from a tapered metal wall installation in Oklahoma to a textured precast concrete solution in North Carolina.