Clemson University has been in the spotlight for the past few months thanks to its thrilling BCS National Championship win. But that doesn’t mean other departments within the university aren’t pulling their weight, too.

Clemson’s School of Architecture has recently received attention for its new framing method: the Sim[PLY] Framing System. The system is created from locally sourced plywood and uses a computer numeric control (CNC) fabricator to cut the components. After being pre-cut and pre-measured, the framing can be flat-packed for shipment, which allows for the use of small transport vehicles.

Beyond the sustainability and transportation benefits, Sim[PLY] provides strong thermal performance. “The wall cavity depth can be easily scaled up or down, for greater or less insulating value, as needed,” says Dustin Albright, Assistant Professor, Clemson School of Architecture. “Moreover, Sim[PLY] walls have minimal thermal bridging compared to inline framing. These measures would otherwise require offset studs or Larsen truss construction, if using conventional lumber.”

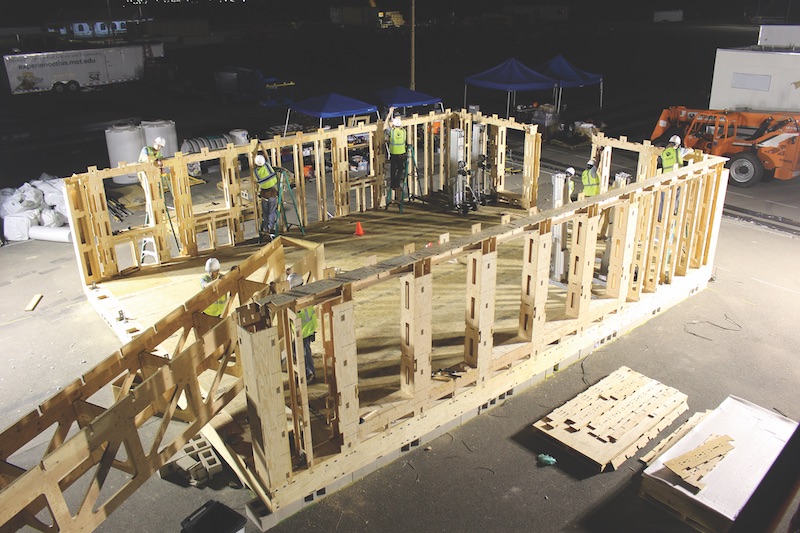

The base of a Sim[PLY] Framing System wall prior to standing it. This wall was part of the initial prototype of the Indigo Pine House, Clemson’s 2015 Solar Decathlon entry. Courtesy Clemson University School of Architecture.

The base of a Sim[PLY] Framing System wall prior to standing it. This wall was part of the initial prototype of the Indigo Pine House, Clemson’s 2015 Solar Decathlon entry. Courtesy Clemson University School of Architecture.

What is really helping to set Sim[PLY] apart from other prefabricated structures is how it is put together. Thanks to a patent-pending interlocking tab-and-slot connection method, the structure can be assembled by unskilled labor without the use of power tools or nails. All that is required to build the structure are steel zip ties and screws.

The connection system means assembling the structure is similar to building a 3D puzzle, and because no nails are used, the system can be disassembled just as easily as it is assembled, without causing any structural damage.

“Non-destructive disassembly involves snipping the cable ties and popping the joints loose with a

mallet. The pieces are then ready to flat-pack and reuse elsewhere,”

says Albright.

Sim[PLY] was used to build CropStop in Greenville, S.C., an incubator kitchen and gathering place that allows crop owners to process their harvests to meet local demand for farm-to-table foods. Albright says Sim[PLY] is “gathering interest” from CropStop partners in Florida, as well.

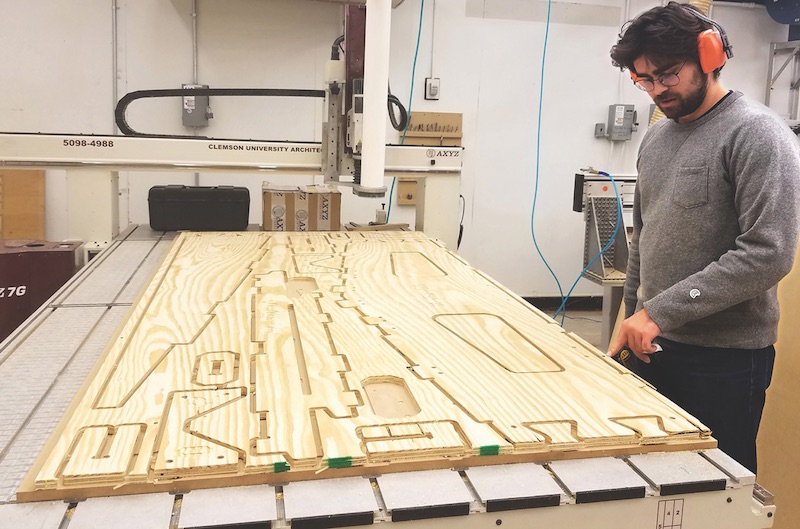

Clemson architecture student Paul Mosher cuts components for a full-scale mockup. Courtesy Clemson University School of Architecture.

Clemson architecture student Paul Mosher cuts components for a full-scale mockup. Courtesy Clemson University School of Architecture.