In the state of Minnesota, winter is unavoidable. Every year we can look forward to each of our 10,000 lakes freezing with a topcoat of ice solid enough to support a semi-trailer. It’s no wonder this state is home to the granddaddy of ice fishing accommodations: Clam Outdoors, the undisputed world leader in ice-fishing house sales.

Clam’s multiple locations and a general lack of space was inefficient and hampering growth. Every day the company spent in its old, widespread facilities was another day of suboptimal performance. Since its humble beginnings in founder Dave Genz’s garage 40 years ago, Clam Outdoors has grown beyond his expectations. In fact, many credit the Minnesota company with revolutionizing the sport of ice fishing. The film Grumpy Old Men may have introduced parts of the country to the idea of fishing on a frozen lake, but the fact is, ice fishing is a huge industry.

Clam was looking to grow quickly, but intelligently. They wanted to bring all aspects of their business together under one roof: manufacturing, distribution and leadership. Any new facility would need to be big, versatile and efficient. Fabcon’s structural precast panels were the perfect solution. The product is ideal for large multi-use projects, especially when speed is a must and critical requirements for a facility are a moving target.

Fabcon installation crews can work efficiently through even the harshest winters, enabling full use of every month of the year.

Fabcon installation crews can work efficiently through even the harshest winters, enabling full use of every month of the year.

Fabcon’s structural precast panels helped an iconic fishing equipment manufacturer accommodate its meteoric growth.

Fabcon Precast partnered with general contractor Kinghorn Construction to erect the 150,000 square-foot facility that Clam now calls home. Clam benefited from a shortened construction cycle and built a structure that will ultimately reduce operating costs and provide much-needed space for product as well as people. The new facility gave Clam the opportunity to grow and come together as an organization. Owner Dave Osborne said, “It was especially nice to have the whole team under one roof.” Previously, the organization was spread out across multiple locations. The new building, however, is large enough to accommodate all of Clam’s brands and operations—bringing everyone together flawlessly. Fabcon Sales Engineer Aaron Gordon explained that their panels were a perfect fit for Clam’s world headquarters: “Their plan called for 24 dock doors of varying sizes and the possibility of an additional 12 doors in future expansion. Our 10-foot panels make it a lot easier to execute that particular feature. Plus, at just over R-28, our panels provide excellent thermal performance and comfort…not unlike a Clam fish house, just on a much larger scale.”

Fabcon’s structural precast panels contribute to a comfortable, versatile building envelope perfectly suited for people and products.

As always, a key advantage to working with Fabcon was their ability to produce panels even before the construction site was ready—a luxury not available with site-cast or block construction methods. “Clam was so pressed for space in their existing facility, they were extremely motivated to get into the new space. We had their new home enclosed within 13 days of the footings being completed,” added Gordon.

Dock doors are a snap with Fabcon’s 10-foot structural precast panels—and Clam’s project featured 24 of them.

Dock doors are a snap with Fabcon’s 10-foot structural precast panels—and Clam’s project featured 24 of them.

Their current site has the potential for an additional 50,000 square feet of expansion. Thanks to the modular aspects of Fabcon’s panels, expanding that footprint will be quick and much less disruptive than it would have been with most other forms of construction. If the plan calls for it, existing wall panels can even be detached and repurposed in the addition. As Clam continues its success story, Fabcon will be a part of it.

Jim Houtman, VP of Sales & Marketing

jim.houtman@fabconprecast.com

Fabcon Precast

fabconprecast.com

(800) 727-4444

Related Stories

| Nov 3, 2011

GREC Architects announces opening of the Westin Abu Dhabi Golf Resort and Spa

The hotel was designed by GREC and an international team of consultants to enhance the offerings of the Abu Dhabi Golf Club without imposing upon the dramatic landscapes of the elite golf course.

| Nov 2, 2011

CRSI’s Manual of Standard Practice now available

This resource contains information on recommended industry practices for estimating, detailing, fabricating, and placing reinforcing steel for reinforced concrete construction.

| Nov 1, 2011

Holcim awards winners for North America announced

A socio-architectural project to create regional food-gathering nodes and a logistics network in Canada's high arctic territory won the top prize for North America of $100,000.

| Oct 14, 2011

ACI partners with CRSI to launch new adhesive anchor certification program

Adhesive anchor installer certification required in new ACI 318-11.

| Oct 12, 2011

FMI’s Construction Outlook: Third Quarter 2011 Report

Construction Market Forecast: The general economy is seeing mixed signs.

| Oct 12, 2011

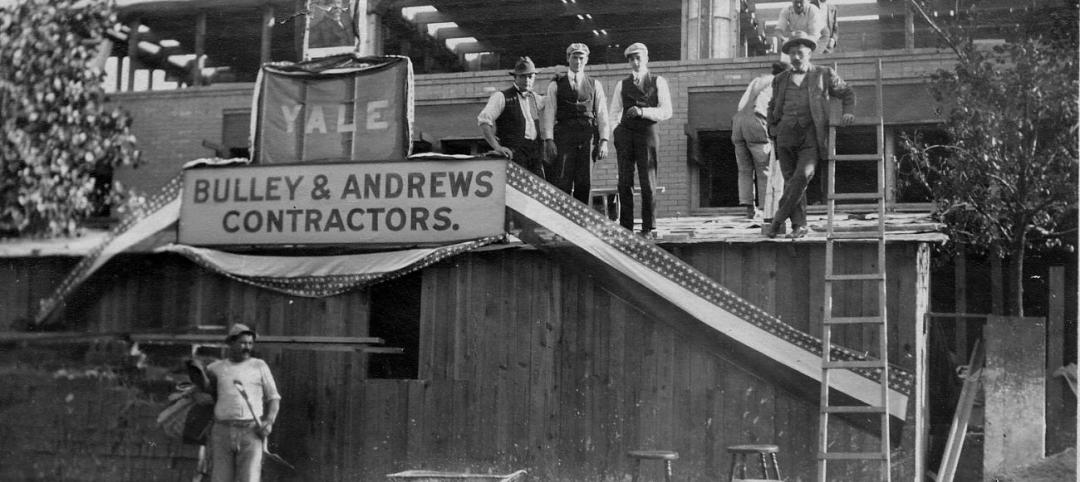

Bulley & Andrews celebrates 120 years of construction

The family-owned and operated general contractor attributes this significant milestone to the strong foundation built decades ago on honesty, integrity, and service in construction.

| Oct 7, 2011

GREENBUILD 2011: Transparent concrete makes its North American debut at Greenbuild

The panels allow interior lights to filter through, from inside.

| Oct 6, 2011

GREENBUILD 2011: Growing green building market supports 661,000 green jobs in the U.S.

Green jobs are already an important part of the construction labor workforce, and signs are that they will become industry standard.

| Oct 5, 2011

GREENBUILD 2011: Sustainable construction should stress durability as well as energy efficiency

There is now a call for making enhanced resilience of a building’s structure to natural and man-made disasters the first consideration of a green building.

| Oct 4, 2011

GREENBUILD 2011

Click here for the latest news and products from Greenbuild 2011, Oct. 4-7, in Toronto.