The produce may be “ugly,” but Misfits Market’s new warehouse is proving to be perfect when it comes to keeping its subscription-based delivery service top shelf—giving customers the opportunity to build out grocery boxes of misshapen but perfectly good quality organic produce and sustainably sourced pantry staples for up to 40% off standard grocery store prices.

Recognizing the need for expansion to its burgeoning business (even before the pandemic, which has increased further the desire for grocery delivery), Misfits Market (originally located in Pennsauken, New Jersey) secured the funds to build a new cold storage warehouse with a large open cold process in their packing area in Delanco, New Jersey, essentially doubling its order capacity throughout the East Coast, and providing the opportunity to bring the service to more Southern and Midwestern markets.

To ensure freezer and refrigerator temperatures remained up to par, Vineland, New Jersey-based general contractor Stanker & Galetto, along with metal panel subcontractor and installer on the project, Rufus Brubaker Refrigeration, selected CF Mesa insulated panels from Metl-Span for the facility.

CF Mesa panels are an ideal—and common—exterior and interior solution, in fact, for cold storage applications including cooler buildings, freezers, food processing buildings, dry goods warehouses, and any all-controlled environment building where temperature control and insulation values are key to functionality. The lightly corrugated profile on both faces creates symmetry on the outside of the building and room to room within, and the minor rib provides a flattened appearance. Additionally, these panels feature easy and fast installation, equating to reduced construction labor costs, as well as easy-to-clean surfaces.

The substantial new construction/greenfield project used approximately 200,000 sq. ft. of 4-inch- thick and 5-inch-thick Metl-Span CF Mesa 42-in. wall panels. The project team relied on a Sandstone color for the exterior building envelope, as the building owners were looking to achieve a beige-colored aesthetic. Metl-Span’s standard interior color, Igloo White, in the meantime, presents a clean, basic design—perfect for the interior wall partitions for cold storage facilities such as this.

Doug Horton, project estimator from refrigeration specialist Rufus Brubaker, notes of the color choices, “When you design a cold storage building, you want to stay within a certain color range. Dark colors, of course, are really not a good idea. With the ‘beige’ directive, Sandstone would be one of the darkest colors we’d use on a cold storage building.”

He further shares that although the popular CF Mesa insulated metal panels were an obvious choice for this type of temperature-sensitive project, they chose Metl-Span in particular due to its reputation for great quality and service throughout the South Jersey area and beyond. “When it comes down to it, Metl-Span is all about customer service. We have a good, ongoing relationship with them. Their plants are well located so we get our deliveries in a better time frame. They’re always good to work with, from their reps to their support staff.”

Metl-Span sales representative, Mike Rauch, explains that when dealing with cold storage, the thickness and performance of the panels are dictated by the temperature within the building. “In this case,” he says, “there were freezers and coolers; in the freezer, the exterior and interior wall panels were five inches, and the 37-degree cooler and 45-degree repack areas were each 4 inches thick.”

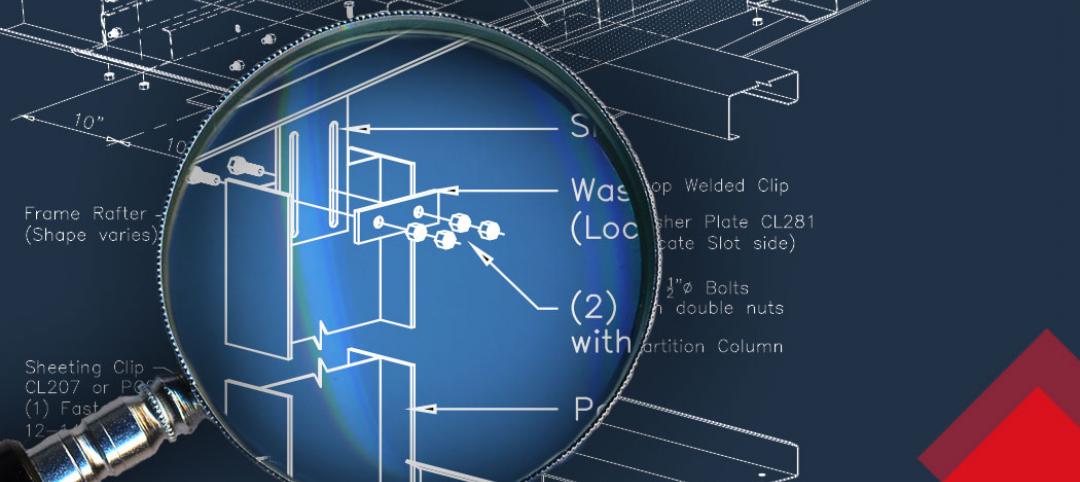

To ensure proper performance, Metl-Span conducted a connection analysis for the customer in order to make sure that thermal bow wouldn’t come into play, a typical challenge with very high buildings. Rauch says, “During the design and bidding phases, we performed a panel attachment analysis to make sure that thermal bow, which can affect these projects heavily, wouldn’t come into play, by providing the proper structure behind the panel.”

As to performance, Metl-Span CF Mesa wall panels utilize a factory foamed-in-place polyurethane core paired with impermeable steel exterior and interior faces, which ensure the highest insulating values throughout the building’s lifecycle. The product’s unique foam core allows the R-value insulation performance to increase as the core temperature of the panel decreases, a feature attributed to the blowing agent used in the production of Metl-Span CF IMPs.

The project started on March 11, 2020 and substantial completion was done on Aug. 31, 2020. Misfits Market, which is now the leading organic direct-to-consumer food subscription and the nation’s fastest-growing grocery delivery service, soon after celebrated the opening of the new state-of-the-art facility in October 2020, thanks in large part to Metl-Span’s ability to deliver its panels on time, and the project team’s determination to get it done, despite pandemic conditions and potential delays.

To quote Chris Nelson, Chief Operating Officer at Misfits Market from an interview in the Philly Inquirer, “The increased capacity and operations sophistication on-site allows us to further expand our product offerings, release new product features, and continue to rescue tens of millions of pounds of produce annually.” That’s a win not only for Misfits Market and its expanding team but also for customers across the country.

Related Stories

| Apr 17, 2014

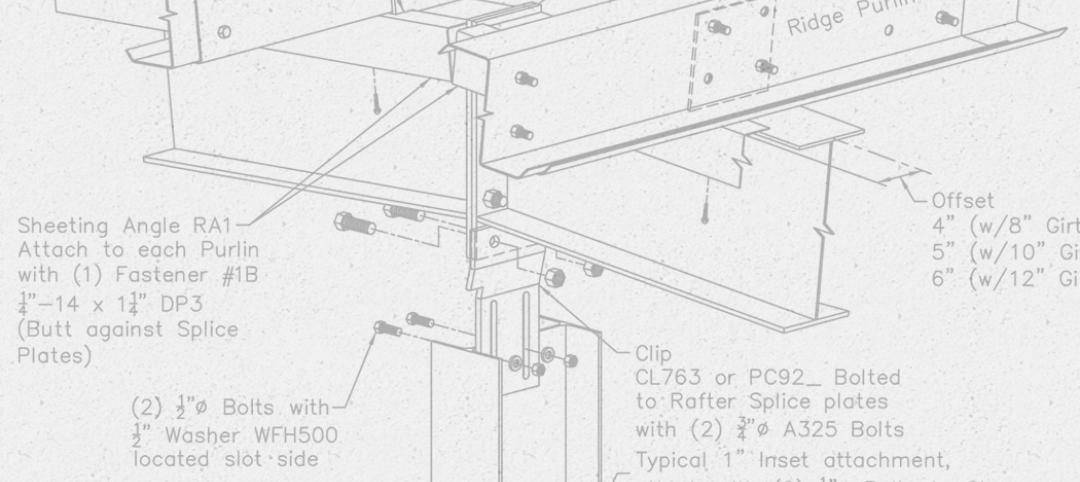

6 details that can throw off your schedule

In 1997, Apple told us to “Think Different.” So we did. We thought about what could happen if the world went mobile, if information was boundless, if we could carry our office in our back pocket. We’ve grown to love different and to expect change. And when it comes to Apple products, that’s not such a bad thing. When it comes to your building order, however, it’s not nearly as appealing.

| Apr 9, 2014

Steel decks: 11 tips for their proper use | BD+C

Building Teams have been using steel decks with proven success for 75 years. Building Design+Construction consulted with technical experts from the Steel Deck Institute and the deck manufacturing industry for their advice on how best to use steel decking.

| Apr 8, 2014

Reflecting on job number 61-001

Job number 61-001 changed everything. It was sold in 1961, a year of change for the nation and for Star. By January, John F. Kennedy would be president. By the end of the year, Star would launch a historic shift in our product and our distribution, a shift still active today.

| Mar 31, 2014

Tips for creating a competitive bid using codes and loads

Landing a project feels like winning a prize, sort of like finding that forgotten $20 bill in the pocket of a pair of jeans you haven’t worn in a while. But living on the “chance” of winning a job isn’t a great way to pay your electric bill. So, how do you swing the chances in your favor?

| Mar 26, 2014

A sales and service showcase

High Plains Equipment, a Case IH dealership in Devils Lake, N.D., constructs a larger facility to better serve its customers.

| Mar 19, 2014

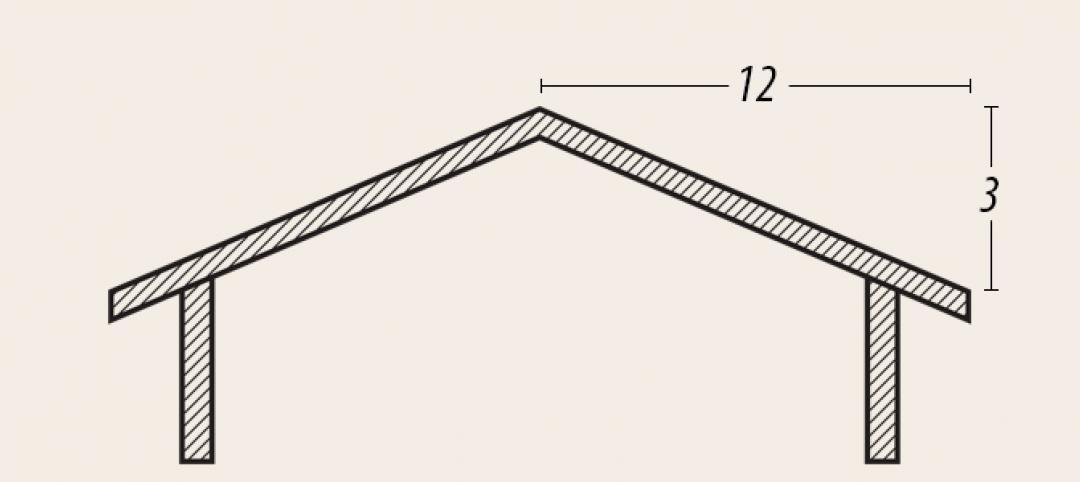

Frames: the biggest value engineering tip

In every aspect of a metal building, you can tweak the cost by adjusting the finish, panel thickness, and panel profile. These changes might make a few percentage points difference in the cost. Change the framing and you have the opportunity to affect 10-20 percent savings to the metal building portion of the project.

| Mar 11, 2014

Why you should start with a builder, part three

We had worked together for 30 years. As a long-standing client of mine, he and I had gone through many projects together. And we were approaching another project, one that would forever change how he viewed our working relationship. As my customer and I sat down to talk about the project details, he told me something that would stay with me for weeks. “Kim, I’m going to have to get other bids on this just so I have peace of mind.”

Sponsored | | Mar 10, 2014

A high-performance barn

Bastoni Vineyards replaces a wooden barn with an efficient metal building used for maintenance, storage, and hosting events.

| Mar 4, 2014

CENTRIA Demonstrates Commitment to Contractors

New Brochure Highlights Architectural Metal Panel Manufacturer’s Products, Expertise and Experience

| Feb 27, 2014

Colorado Coalition Plans Welcoming Events for METALCON International Visitors

Visitors to the 24th METALCON International, slated for October 1-3 at the Colorado Convention Center in Denver, will get a royal welcome from local companies involved in the show. Denver-based New Tech Machinery and Colorado Springs-based S-5! Solutions have formed the Colorado Coalition as a way of encouraging visitors to learn about Colorado before they arrive and for Coloradans to experience METALCON.