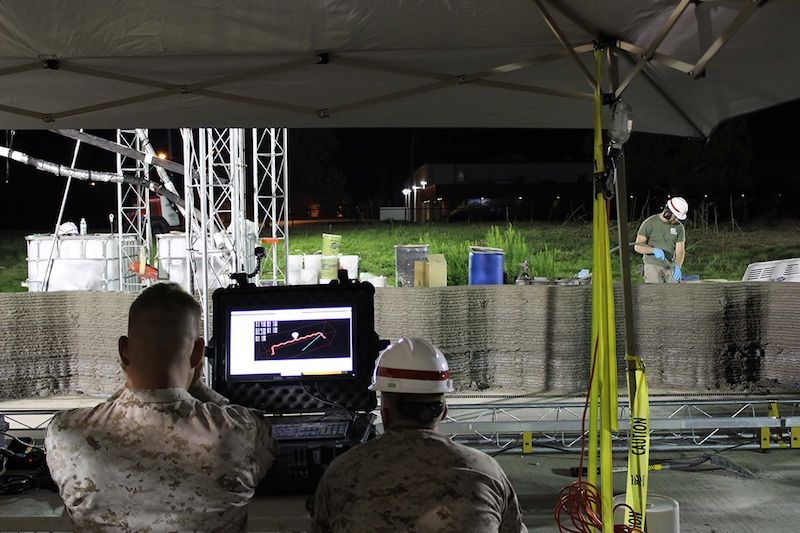

The Additive Manufacturing Team at Marine Corps Systems Command (MCSC) and Marines from I Marine Expeditionary Force recently teamed up at the U.S. Army Engineer Research and Development Center to 3D print a barracks.

The team used a computer-aided design model on a 10-year-old computer, concrete, and a 3D printer to create the 500-sf building. The job took 40 hours, but the Marines claim if there was a robot to do the mixing and pumping, the building could easily be created in one day. Typically, it takes 10 Marines five days to build a barracks out of wood.

See Also: Dubai plans to 3D print 25% of every new building by 2025

According to Capt. Matthew Friedell, AM project officer in MCSC’s Operations and Programs/G-3, nothing like this has been done before. “People have printed buildings and large structures, but they haven’t done it onsite and all at once. This is the first-in-the-world onsite, continuous concrete print,” Friedell said in a release.

Not only does using a concrete printer expedite barracks construction, but it can also help keep Marines safe. “In active or simulated combat environments, we don’t want Marines out there swinging hammers and holding plywood up. Having a concrete printer that can make buildings on demand is a huge advantage for Marines operating down range,” says Friedell.

The Marine Corps is currently staffing a deliberate urgent needs statement and concept of employment for this technology. The results of the field user evaluation will inform future requirements to give the Corps a concrete construction additive manufacturing program of record.

For more information, click here.

Related Stories

| May 30, 2018

Accelerate Live! talk: Seven technologies that restore glory to the master builder

In this 15-minute talk at BD+C’s Accelerate Live! conference (May 10, 2018, Chicago), AEC technophile Rohit Arora outlines emerging innovations that are poised to transform how we design and build structures in the near future.

3D Printing | Nov 21, 2017

Europe’s first 3D-printed building has been completed

Construction ran a few weeks behind schedule, but the 3D printing wasn’t to blame.

Codes and Standards | Aug 8, 2017

3D printing industry working to implement standards for products, processes

Additive Manufacturing Standardization Collective (AMSC) will develop industry-wide additive manufacturing standards and specifications.

Accelerate Live! | Jul 6, 2017

Watch all 20 Accelerate Live! talks on demand

BD+C’s inaugural AEC innovation conference, Accelerate Live! (May 11, Chicago), featured talks on machine learning, AI, gaming in construction, maker culture, and health-generating buildings.

Building Team Awards | Jun 14, 2017

3D-printed office: Office of the Future

Dubai kicks off 3D-printing tech initiative with a novel office project.

3D Printing | Jun 14, 2017

This is the world’s first building completely 3D printed onsite

The building is a lab for research on drones and 3D printing technology.

| Jun 13, 2017

Accelerate Live! talk: Incubating innovation through R&D and product development, Jonatan Schumacher, Thornton Tomasetti

Thornton Tomasetti’s Jonatan Schumacher presents the firm’s business model for developing, incubating, and delivering cutting-edge tools and solutions for the firm, and the greater AEC market.

3D Printing | Apr 17, 2017

The Tokyo Pod Vending Machine resembles a giant game of Tetris in the sky

The building is designed to print and dispense its own dwellings in vending machine-obsessed Tokyo.

University Buildings | Oct 19, 2016

UC Merced to nearly double its size by 2020

Its growth strategy includes adding 1.2 million sf of space for teaching, housing, and research.

3D Printing | Jun 14, 2016

By 2021, 3D concrete printing is projected to be a $56.4 million industry

The 3D concrete printing industry is expected to more than double in size within the next five years.