Next February, FullStack Modular, a leading supplier of prefabricated modules, is scheduled to begin production for its first project in California, a, 86,000-sf, six-story, 143-room hotel that will be the Treehouse Hotel brand’s debut in the United States.

Starwood Capital Group launched Treehouse in 2019 as a eco-friendly lifestyle concept. It currently operates three properties in the United Kingdom, and is developing the U.S. project through its brands management company SH Hotels and Resorts. Its American hotel will be located in Sunnyvale, Calif., and is expected to open late next year. (Starwood is also repurposing several existing structures onsite for additional hotel rooms and suites.)

In an interview with BD+C, Roger Krulak, FullStack Modular’s president and founder, said that his company will produce 200 modules for this project from its manufacturing plant in Portland, Ore. (FullStack’s other plant is in Brooklyn, N.Y.) He estimates that the production would take less than six months, and assembly another three months. Scottsdale, Ariz.-based Synergy Modular is the project’s general contractor.

Krulak believes that Starwood chose FullStack Modular for its fully integrated system approach: its modules are delivered with electrical, plumbing, and mechanical components and systems installed. The building’s façade is also installed at the factory, as are each units’ fixtures and finishes. The building doesn’t require a concrete core and, where necessary, can be rigged at the factory for seismic resistance. Even furniture can be included. The only on-site construction, said Krulak, involves the building’s hallways and elevators.

According to Starwood, the majority of Treehouse’s rooms will provide private outdoor spaces that include ground floor patios and balconies and terraces on the upper floors.

“The FullStack Modular system is one of the most volumetric modular systems anywhere,” said Andy Nuessle, Synergy Modular’s president, in a prepared statement. “The hotel is 100 percent modular from the foundation to the roof.”

Starwood Capital has not disclosed the cost of the Sunnyvale Treehouse Hotel. On its website, FullStack Modular states that, in general, modular production reduces construction costs by as much as 20 percent, construction time by as much as 50 percent, and construction waste by as much as 67 percent. Krulak estimated that the Sunnyvale project will be completed 30 to 40 percent faster than it would were it build using convention on-site construction methods.

A sliver, but increasing

The Modular Building Institute estimates that buildings assembled from modules produced offsite accounted for 5.52 percent of all new construction in North America in 2021. That represented a doubling of market share in five years, and Tom Hardiman, the Institute’s executive director, told the website Construction Dive that he expects modular’s share to rise to 10 percent by 2026.

Krulak is also optimistic about modular’s growth, especially on the residential side. “Housing in the U.S. is at a huge deficit, and construction has no capacity to meet that need. So off-site solutions are picking up significantly. We get a call almost every day.”

Krulak said that FullStack Modular is looking at “a number of opportunities” in the U.S. and internationally. Earlier this month, the company announced it had entered into a strategic alliance with Saudi Arabian Baytur Construction to pursue opportunities for Vision 2030, a large-scale hospitality and urban tourism initiative whose key goal is to increase the Kingdom’s overall hospitality capacity by more than 70,000 hotel rooms.

Related Stories

| Apr 23, 2014

Developers change gears at Atlantic Yards after high-rise modular proves difficult

At 32 stories, the B2 residential tower at Atlantic Yards has been widely lauded as a bellwether for modular construction. But only five floors have been completed in 18 months.

| Apr 17, 2014

6 details that can throw off your schedule

In 1997, Apple told us to “Think Different.” So we did. We thought about what could happen if the world went mobile, if information was boundless, if we could carry our office in our back pocket. We’ve grown to love different and to expect change. And when it comes to Apple products, that’s not such a bad thing. When it comes to your building order, however, it’s not nearly as appealing.

| Apr 9, 2014

Steel decks: 11 tips for their proper use | BD+C

Building Teams have been using steel decks with proven success for 75 years. Building Design+Construction consulted with technical experts from the Steel Deck Institute and the deck manufacturing industry for their advice on how best to use steel decking.

| Apr 2, 2014

8 tips for avoiding thermal bridges in window applications

Aligning thermal breaks and applying air barriers are among the top design and installation tricks recommended by building enclosure experts.

| Mar 31, 2014

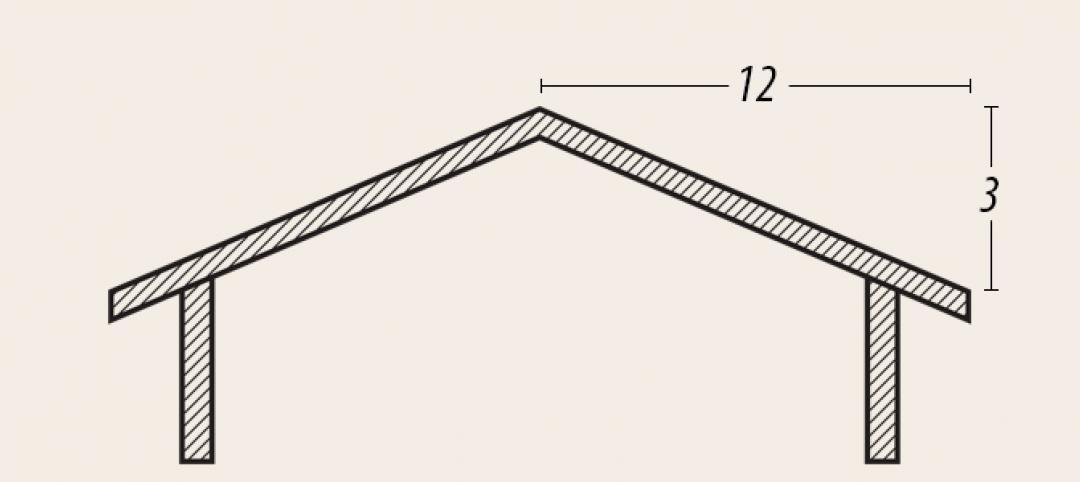

Tips for creating a competitive bid using codes and loads

Landing a project feels like winning a prize, sort of like finding that forgotten $20 bill in the pocket of a pair of jeans you haven’t worn in a while. But living on the “chance” of winning a job isn’t a great way to pay your electric bill. So, how do you swing the chances in your favor?

| Mar 26, 2014

A sales and service showcase

High Plains Equipment, a Case IH dealership in Devils Lake, N.D., constructs a larger facility to better serve its customers.

| Mar 26, 2014

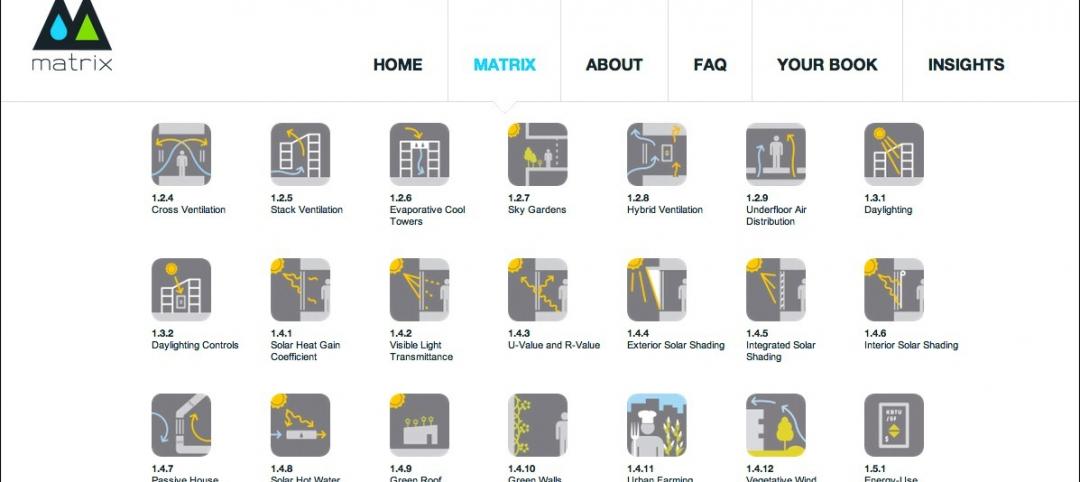

Callison launches sustainable design tool with 84 proven strategies

Hybrid ventilation, nighttime cooling, and fuel cell technology are among the dozens of sustainable design techniques profiled by Callison on its new website, Matrix.Callison.com.

| Mar 20, 2014

Common EIFS failures, and how to prevent them

Poor workmanship, impact damage, building movement, and incompatible or unsound substrate are among the major culprits of EIFS problems.

| Mar 19, 2014

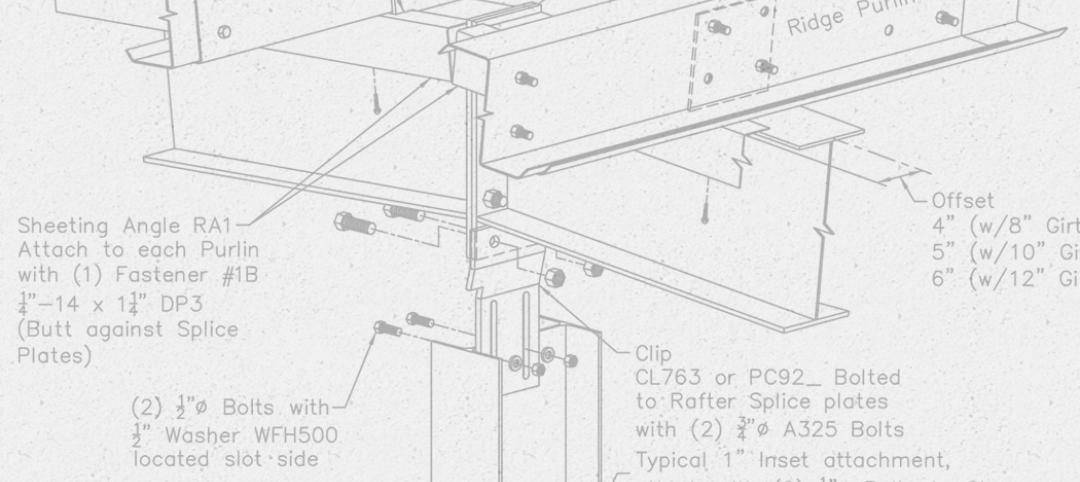

Frames: the biggest value engineering tip

In every aspect of a metal building, you can tweak the cost by adjusting the finish, panel thickness, and panel profile. These changes might make a few percentage points difference in the cost. Change the framing and you have the opportunity to affect 10-20 percent savings to the metal building portion of the project.

| Mar 17, 2014

Rem Koolhaas explains China's plans for its 'ghost cities'

China's goal, according to Koolhaas, is to de-incentivize migration into already overcrowded cities.