Winter Construction in Freeport, Illinois, is family owned and operated. Mark Winter, president, is the third generation to work at the company, his son Scott continues as the in-house architect, his sister-in-law is CFO, and other family members participate on a part-time basis. Recently, the Winters started another family business, Generations Brewing Company, where Mark’s other son, Steven, is the brewmaster. Mark says that one of the benefits of working with family is that you can totally trust your people. Perhaps that's why, when they were ready to build their brewery and tasting room, they decided to ‘keep it in the family’ in terms of construction, too. Winter Construction is part of the Star family, and their new 8300 sf facility is a Star Building System.

According to the architect, Scott Winter, AIA LEED AP, the building’s style is “Agricultural meets Industrial.” The cross-sectional shape that it presents to the world “recalls a barn with a lean-to off to one side, something people often used to do. We were trying to make this building as unique as possible within a tight budget, so we knew Star was a good choice for the job.”

This off-center barn shape is echoed in the massive hops-frame that marks the end of the beer garden area in front of the brewery. The frame is made of salvaged rafters from a local armory. “The hops-frame speaks to the heavy beams of a barn,” explains Scott Winter, “but for brewing, of course, we wanted to have a steel-frame structure.”

The “industrial” aspect of the design is seen in the skin that Winter used to clad this agricultural shape. The roof is Double-Lok standing seam metal roof with a Galvalume Plus finish. Siding is a mixture of AVP (used vertically) with exposed fasteners and a siliconized polyester finish and PBC with a Galvalume Plus finish. “Galvanized steel is a traditional agricultural material. We like that. We used that on the interior walls in some locations, as well.”

“We were able to fast-track design,” recalls company president Mark Winter. “Because the engineering was complete, we were able to begin pouring the foundation before the design was fully approved. We were able to complete interior design while we were already constructing.” He also points out that the time of year when they started, in January, would have prohibited constructing a masonry building. “We would have had to wait two to three months,” he says.

The 60-foot clear-span interior is divided into two main areas, a 6550 sf brewery, and a 1750 sf tasting room. The mezzanine runs through both spaces. In the brewery, the mezzanine is used for storage, and the area under it houses the mill used to crack the grain.

The interior design is full of hints of the Agricultural/Industrial theme: tasting room tables with bases made of black iron pipe, an iron-pipe chandelier, and light fixtures made from metal grain buckets. The large sliding door in front is made from salvaged barn siding.

Construction was completed in May 2014. Brewing equipment was installed, connected, and operational by October, and they had their first beer in the second week of November.

“It’s instantly become one of the hottest places in town to go,” continues Winter. “Something with a little edge, something different. Craft beer is just exploding, even in small towns like Freeport. They say they only drink light beer, but they come in and try ‘Pretzel City Amber,’ and they’re amazed. That’s our flagship beer.” Their other ten varieties include ‘Live Free Porter,’ ‘Hella Good Lager,’ and ‘No Call, No Show,’ a 10% alcohol beer that, Mark Winter says, was named because “that’s what you do the next day at work: no call, no show.”

Just 15 months after opening, they already have about 100 accounts—restaurant, bars, supermarkets, etc.—in a four-county area, in addition to their own tasting-room/beer garden customers. The brewery grounds include 23 acres, currently tilled for growing corn and hay, but in the long term, they intend to grow their own hops on the property, keeping it in the family.

Related Stories

Sponsored | BD+C University Course | May 10, 2022

Designing smarter places of learning

This course explains the how structural steel building systems are suited to construction of education facilities.

Sponsored | BD+C University Course | Apr 19, 2022

Multi-story building systems and selection criteria

This course outlines the attributes, functions, benefits, limits, and acoustic qualities of composite deck slabs. It reviews the three primary types of composite systems that represent the full range of long-span composite floor systems and examines the criteria for their selection, design, and engineering.

Contractors | Mar 28, 2022

Amid supply chain woes, building teams employ extreme procurement measures

Project teams are looking to eliminate much of the guesswork around product availability and price inflation by employing early bulk-purchasing measures for entire building projects.

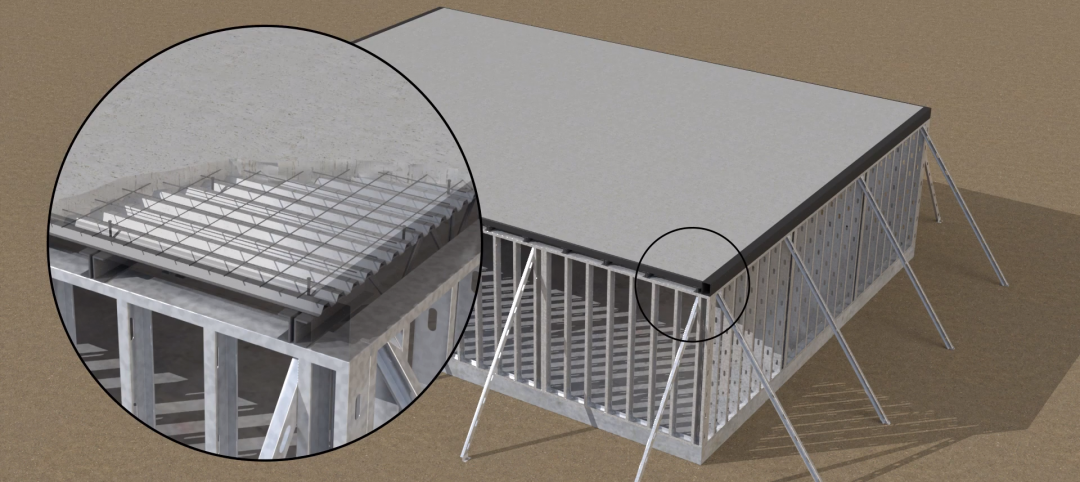

Sponsored | BD+C University Course | Jan 30, 2022

Optimized steel deck design

This course provides an overview of structural steel deck design and the ways to improve building performance and to reduce total-project costs.

Sponsored | Steel Buildings | Jan 25, 2022

Structural Game Changer: Winning solution for curved-wall gymnasium design

Sponsored | Steel Buildings | Jan 25, 2022

Multifamily + Hospitality: Benefits of building in long-span composite floor systems

Long-span composite floor systems provide unique advantages in the construction of multi-family and hospitality facilities. This introductory course explains what composite deck is, how it works, what typical composite deck profiles look like and provides guidelines for using composite floor systems. This is a nano unit course.

Sponsored | BD+C University Course | Jan 12, 2022

Total steel project performance

This instructor-led video course discusses actual project scenarios where collaborative steel joist and deck design have reduced total-project costs. In an era when incomplete structural drawings are a growing concern for our industry, the course reveals hidden costs and risks that can be avoided.

Sponsored | BD+C University Course | Oct 15, 2021

7 game-changing trends in structural engineering

Here are seven key areas where innovation in structural engineering is driving evolution.