As municipalities build out available real estate, virgin ground is eventually exhausted. And abandoned or blighted “brownfield” locations like munitions factories, steel mills and chemical plants become viable options to build. But that doesn’t come without its challenges.

REDEVELOP. BUT FIRST, REMEDIATION.

While existing structures may be visible to the eye, the real trouble lies in the unseen: namely the hazardous substances, pollutants or contaminants that remain in the soil.

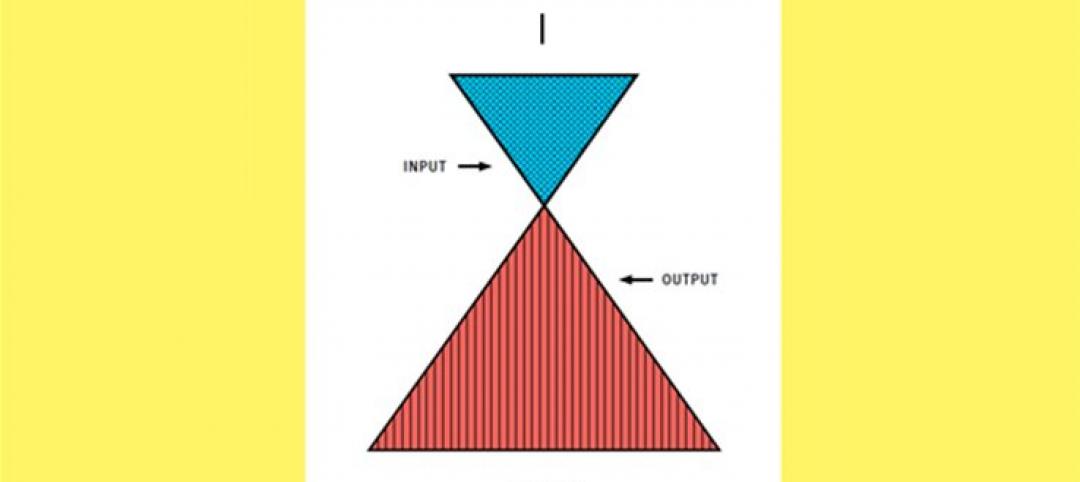

“Brownfields are locations with soil that has been really damaged or abused over time by industry,” said Fabcon’s Aaron Gordon. “Something that’s not suitable for building. And a lot of times has to be capped.” So while redevelopment may include the razing or repurposing of existing structures, the most important step in the process is decontamination and remediation of the soil on site.

THE ADVANTAGES OF PRECAST

Brownfield projects typically involve moving massive amounts of soil. Geotechnical and environmental site conditions are considered as contaminated soil is removed and new fill is brought in. While it’s well known that Fabcon precast panels are light on a budget, the actual panels are also lighter per square foot than competitors. This creates efficiencies in the engineering requirements for preparing the site. “The engineer of record works to ensure the soil pressure is there to handle the large footprint of these industrial buildings,” said Gordon. “Our panels are lighter per square foot. And that helps in designing that footing.” But there are also code requirements to consider and the desire for energy efficiencies. That’s why many builders look to our 12” VersaCore+Green™ sandwich panels and their impressive R-value of 28.2.

WIDE RANGING POSSIBILITIES

Fabcon has played a role in many interesting brownfileld projects – highlighted by three in our home state of Minnesota.

Northern Stacks is a 122-acre business park in Fridley, Minnesota features state-of-the-art office and warehousing space just steps from the Missippi River where factories once turned out guns for U.S. Naval vessels during World War II.

Northern Stacks - Fridley, Minnesota. Photo Credit: Fabcon

Northern Stacks - Fridley, Minnesota. Photo Credit: Fabcon

Featuring a mix of rehabbed structures and new construction, the city of Duluth redeveloped a former iron foundry and heavy machinery shop at Clyde Park into a multiuse destination. The development is now home to the Duluth Heritage Sports Center, the Duluth Children’s Museum, and Clyde Iron Works, a restaurant and events center.

And finally, the St. Paul Port Authority helped turn a decrepit bowling alley built atop an abandoned city dump along the Missippi Riverfront into a new company headquarters for River of Goods/Terrybear Urns & Memorials. And collaborated to install community gardens in the adjacent greenspace.“In each of these projects we we’re able to contribute to adding a fresh new look and functionality,” said Gordon. “Then people and businesses can start moving back into these communities that were lost along the way.”

For more information on Fabcon Precast, visit fabcon-usa.com.

Related Stories

| Feb 5, 2014

Extreme conversion: Atlanta turns high-rise office building into high school

Formerly occupied by IBM, the 11-story Lakeside building is the new home for North Atlanta High School.

| Feb 5, 2014

7 towers that define the 'skinny skyscraper' boom [slideshow]

Recent advancements in structural design, combined with the loosening of density and zoning requirements, has opened the door for the so-called "superslim skyscraper."

| Jan 28, 2014

2014 predictions for skyscraper construction: More twisting towers, mega-tall projects, and 'superslim' designs

Experts from the Council on Tall Buildings and Urban Habitat release their 2014 construction forecast for the worldwide high-rise industry.

| Jan 24, 2014

Structural concrete requirements under revision: ACI 318 standard

The American Concrete Institute (ACI), an organization whose mission is to develop and disseminate consensus-based knowledge on concrete and its uses, is finalizing a completely reorganized ACI 318-14: Building Code Requirements for Structural Concrete.

| Jan 7, 2014

Concrete solutions: 9 innovations for a construction essential

BD+C editors offer a roundup of new products and case studies that represent the latest breakthroughs in concrete technology.

| Dec 12, 2013

Book announcement: The economic performance of sustainable construction

Thirty specialists from around the world challenge the question of (higher) costs related to sustainability of the built environment

| Dec 10, 2013

16 great solutions for architects, engineers, and contractors

From a crowd-funded smart shovel to a why-didn’t-someone-do-this-sooner scheme for managing traffic in public restrooms, these ideas are noteworthy for creative problem-solving. Here are some of the most intriguing innovations the BD+C community has brought to our attention this year.

| Nov 27, 2013

Wonder walls: 13 choices for the building envelope

BD+C editors present a roundup of the latest technologies and applications in exterior wall systems, from a tapered metal wall installation in Oklahoma to a textured precast concrete solution in North Carolina.

High-rise Construction | Jul 9, 2013

5 innovations in high-rise building design

KONE's carbon-fiber hoisting technology and the Broad Group's prefab construction process are among the breakthroughs named 2013 Innovation Award winners by the Council on Tall Buildings and Urban Habitat.

| Jun 4, 2013

SOM research project examines viability of timber-framed skyscraper

In a report released today, Skidmore, Owings & Merrill discussed the results of the Timber Tower Research Project: an examination of whether a viable 400-ft, 42-story building could be created with timber framing. The structural type could reduce the carbon footprint of tall buildings by up to 75%.