Later this year, the new 459-ft-tall East Side Tower in Berlin, Germany, will be the first building in the world to install an elevator system that travels both vertically and horizontally.

Later this year, the new 459-ft-tall East Side Tower in Berlin, Germany, will be the first building in the world to install an elevator system that travels both vertically and horizontally.

OVG Real Estate and FREO Group, the building’s developers, are working in partnership with thyssenkrupp, one of the world’s largest industrial groups, whose thyssenkrupp Elevator division has devised MULTI, the first cable-free elevator that moves sideways as well as up and down.

Thyssenkrupp unveiled this concept in 2014, and after two-and-a-half years of construction demonstrated MULTI last month at its 807-ft-tall, 12-shaft innovation test tower in Rottweil, Germany. This tower can test elevator speeds up to 22.45 miles per hour. Three of its shafts were designed specifically for certifying the new cable-free elevator system.

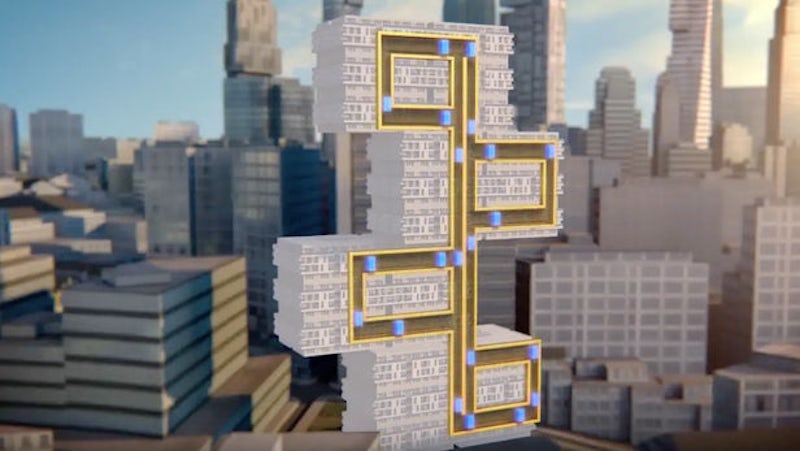

MULTI operates along the same principals as a metro system. Image: Thyssenkrupp

MULTI operates along the same principals as a metro system. Image: Thyssenkrupp

Instead of one cabin per shaft moving up and down, MULTI offers multiple cabins operating in loops, similar to a metro system but inside a building. Its exchange system allows the linear drive and guiding equipment to make 90-degree turns by leveraging the linear motor technology developed for the magnetic levitation Transrapid train. MULTI runs on a multi-level brake system and redundant wireless data and energy management system on the cars.

A short animated video of how this system works can be seen here.

Nearly 200 building industry representatives attended the demonstration, including Antony Wood, Executive Director of the Council on Tall Buildings and Urban Habitat. Wood calls MULTI “perhaps the biggest development in the elevator industry since the invention of the safety elevator some 165 years ago.”

At a time when developers are challenging AEC firms to come up with new and faster ways to transport people in taller buildings. MULTI is promising 50% higher transport capacities. Image: thyssenkrupp

As cities expand and buildings get larger and taller to accommodate more people, planners and architects face significant challenges around moving people comfortably and quickly to their destinations. McKinsey Global Institute estimates that cities will need to construct floor space equivalent to 85 percent of all of today’s residential and commercial building stock by 2025.

To that end, thyssenkrupp claims that MULTI can achieve up to 50% higher transport capacity and reduce peak power demand by as much as 60% when compared to conventional elevator systems.

MULTI requires fewer and smaller shafts than conventional elevators and can increase the building’s usable area by up to 25%. (Thyssenkrupp notes that current elevator-escalator footprints can occupy up to 40% of a high rise building’s floor space, depending on the building height.) The system will also reduce the wait time for a ride to between 15 and 30 seconds.

In April, MULTI took top honors at the 2017 Edison Awards in New York, an annual competition honoring new product and service excellence. The first MULTI system will be installed in the East Side Tower, which is scheduled for completion by 2019. In an interview with Wired magazine, thyssenkrupp's CEO Andreas Schierenbeck said that while MULTI could cost between three and five times more than a standard lift system, the space savings in a large building are “definitely overcompensating the price of the product.”

Related Stories

Industrial Facilities | Apr 9, 2024

Confessions of a cold storage architect

Designing energy-efficient cold storage facilities that keep food safe and look beautiful takes special knowledge.

AEC Innovators | Feb 28, 2024

How Suffolk Construction identifies ConTech and PropTech startups for investment, adoption

Contractor giant Suffolk Construction has invested in 27 ConTech and PropTech companies since 2019 through its Suffolk Technologies venture capital firm. Parker Mundt, Suffolk Technologies’ Vice President–Platforms, recently spoke with Building Design+Construction about his company’s investment strategy.

MFPRO+ Special Reports | Feb 22, 2024

Crystal Lagoons: A deep dive into real estate's most extreme guest amenity

These year-round, manmade, crystal clear blue lagoons offer a groundbreaking technology with immense potential to redefine the concept of water amenities. However, navigating regulatory challenges and ensuring long-term sustainability are crucial to success with Crystal Lagoons.

AEC Tech | Feb 20, 2024

AI for construction: What kind of tool can artificial intelligence become for AEC teams?

Avoiding the hype and gathering good data are half the battle toward making artificial intelligence tools useful for performing design, operational, and jobsite tasks.

Building Tech | Feb 20, 2024

Construction method featuring LEGO-like bricks wins global innovation award

A new construction method featuring LEGO-like bricks made from a renewable composite material took first place for building innovations at the 2024 JEC Composites Innovation Awards in Paris, France.

Modular Building | Jan 19, 2024

Building with shipping containers not as eco-friendly as it seems

With millions of shipping containers lying empty at ports around the world, it may seem like repurposing them to construct buildings would be a clear environmental winner. The reality of building with shipping containers is complicated, though, and in many cases isn’t a net-positive for the environment, critics charge, according to a report by NPR's Chloe Veltman.

Sponsored | BD+C University Course | Jan 17, 2024

Waterproofing deep foundations for new construction

This continuing education course, by Walter P Moore's Amos Chan, P.E., BECxP, CxA+BE, covers design considerations for below-grade waterproofing for new construction, the types of below-grade systems available, and specific concerns associated with waterproofing deep foundations.

Mass Timber | Jan 2, 2024

5 ways mass timber will reshape the design of life sciences facilities

Here are five reasons why it has become increasingly evident that mass timber is ready to shape the future of laboratory spaces.

Sustainability | Nov 1, 2023

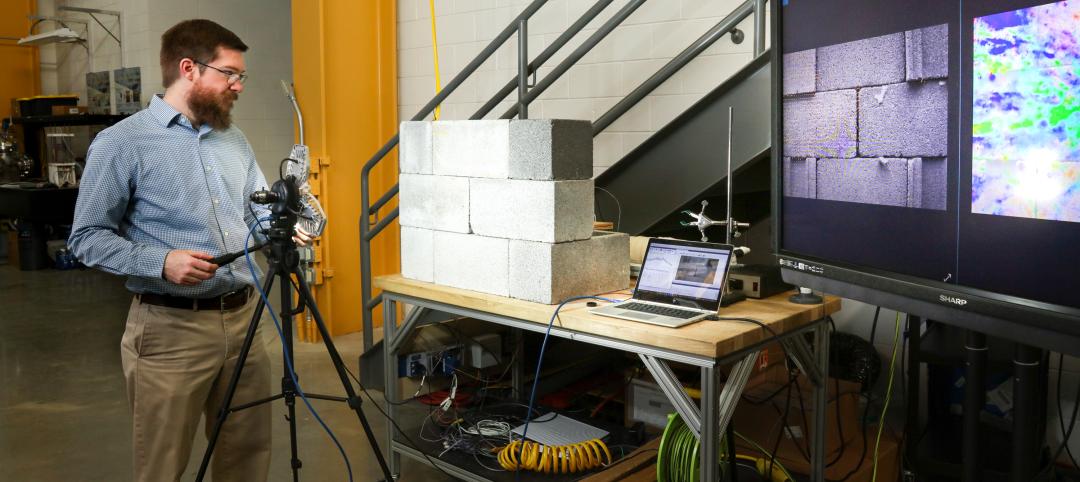

Researchers create building air leakage detection system using a camera in real time

Researchers at the U.S. Department of Energy’s Oak Ridge National Laboratory have developed a system that uses a camera to detect air leakage from buildings in real time.

Engineers | Oct 12, 2023

Building science: Considering steel sheet piles for semi-permanent or permanent subsurface water control for below-grade building spaces

For projects that do not include moisture-sensitive below-grade spaces, project teams sometimes rely on sheet piles alone for reduction of subsurface water. Experts from Simpson Gumpertz & Heger explore this sheet pile “water management wall” approach.