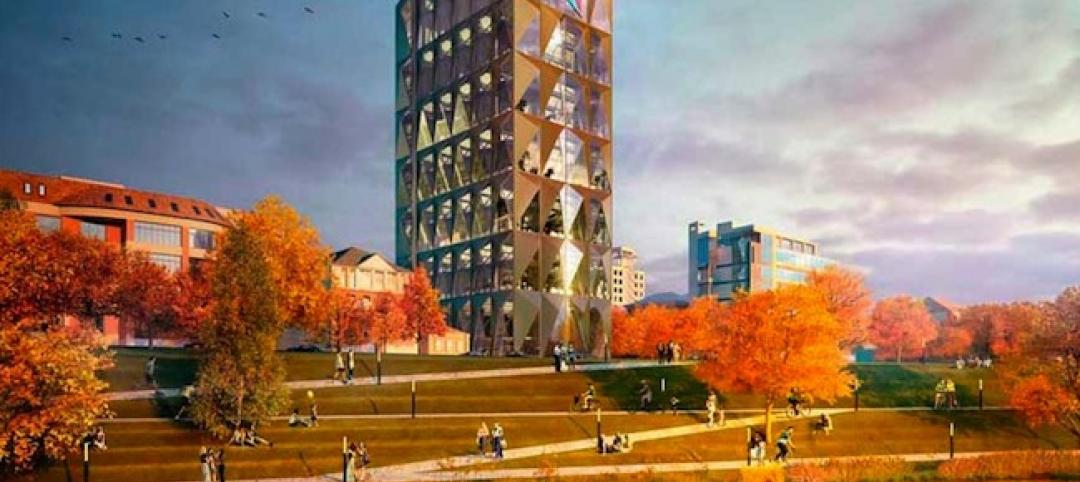

Frigerio Design Group, after winning a competition to design a new technical center for Ferrero in Alba, Italy, has recently unveiled more details for the project.

The proposal for the Italian multinational food company's new facility was selected for the human values of its design proposal, which features an industrial structure integrated into the landscape. The project was inspired by the scenery, nature, and colors of the Langhe, the hilly area located in the Piedmont region of northern Italy.

The Ferrero Technical Center stems from the need to combine the company’s engineering operations, in particular those devoted to designing new production lines, with the workshop where they are developed. These functions are not currently located within the factory.

The center will be a 136,700-sf ecological building that is nZEB (nearly Zero Energy Building) and will house 200 employees. It will be able to support management and operational functions for automated and interconnected production.

Simple and linear architecture conceals plants and technical equipment while maximizing all of the passive space and minimizing the resources needed for operations and maintenance. Technology is ubiquitous throughout the new center without ever becoming obtrusive. It is seamlessly integrated in a recognizable and reassuring architecture.

Transparency and opacity define the architecture of the building. The offices located on the top floor have transparent facades while the lower floors containing the workshop and plants are hidden from view. The great hall is entirely glazed and covers one end from ground to roof with a grand staircase that connects the building’s three floors.

The workshop is designed with a minimal and essential floorpan where white is the primary color. Openings in the facade capture natural light while preventing direct sunlight. The curtain walls in this area will have micro-perforated and sound-absorbing panels to improve the quality of internal acoustics and minimize any sound pollution.

Six green areas, dubbed the flying gardens by the architect, will perform a bioclimatic, acoustic, and aesthetic function on the top floor near the offices. Additionally, a photovoltaic system on the roof generates a peak of 300 kW.

The project broke ground in 2020 and is slated for completion in December 2021.

Related Stories

Sponsored | | Jul 17, 2014

A major hop forward

The construction of efficient metal buildings has helped Perrault Farms expand its hops-harvesting business.

| Jul 14, 2014

Foster + Partners unveils triple-glazed tower for RMK headquarters

The London-based firm unveiled plans for the Russian Copper Company's headquarters in Yekaterinburg.

| Jul 10, 2014

Berkeley Lab opens 'world's most comprehensive building efficiency simulator'

DOE’s new FLEXLAB is a first-of-its-kind simulator that lets users test energy-efficient building systems individually or as an integrated system, under real-world conditions.

| Jul 7, 2014

7 emerging design trends in brick buildings

From wild architectural shapes to unique color blends and pattern arrangements, these projects demonstrate the design possibilities of brick.

| Jul 2, 2014

Emerging trends in commercial flooring

Rectangular tiles, digital graphic applications, the resurgence of terrazzo, and product transparency headline today’s commercial flooring trends.

| Jun 30, 2014

Report recommends making infrastructure upgrades a cabinet-level priority

The ASCE estimates that $3.6 trillion must be invested by 2020 to make critically needed upgrades and expansions of national infrastructure—and avoid trillions of dollars in lost business sales, exports, disposable income, and GDP.

Sponsored | | Jun 27, 2014

SAFTI FIRST Now Offers GPX Framing with Sunshade Connectors

For the Doolittle Maintenance Facility, SAFTI FIRST provided 60 minute, fire resistive wall openings in the exterior using SuperLite II-XL 60 insulated with low-e glazing in GPX Framing with a clear anodized finish.

| Jun 18, 2014

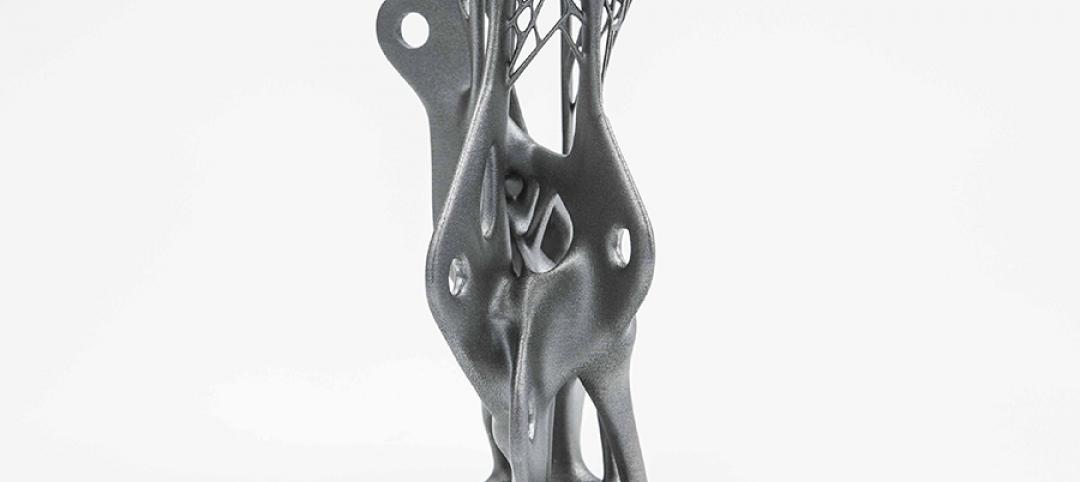

Arup uses 3D printing to fabricate one-of-a-kind structural steel components

The firm's research shows that 3D printing has the potential to reduce costs, cut waste, and slash the carbon footprint of the construction sector.

| Jun 16, 2014

6 U.S. cities at the forefront of innovation districts

A new Brookings Institution study records the emergence of “competitive places that are also cool spaces.”

| Jun 12, 2014

Austrian university develops 'inflatable' concrete dome method

Constructing a concrete dome is a costly process, but this may change soon. A team from the Vienna University of Technology has developed a method that allows concrete domes to form with the use of air and steel cables instead of expensive, timber supporting structures.