Constructing contemporary building enclosures while avoiding installation problems during construction and performance problems in service is an unrelenting challenge for Building Teams. The margin for error is minimal. Increasingly complex building designs, thin profit margins, and demanding schedules do not allow for rework during construction, nevermind callbacks and disputes after occupancy.

In the mechanical/electrical/plumbing (MEP) realm, a well-established practice for managing these challenges during the preconstruction phase is the “coordination drawings” process. In stark contrast, building enclosure preconstruction coordination (or lack thereof) is typically characterized by shop drawings focused on each enclosure component separately, with a generic representation of the adjacent construction.

Although most of this article discusses the general and trade contractors’ efforts during the preconstruction/construction phase, a fair discussion on shop drawings is incomplete without emphasizing the importance of the design documentation.

The designer of record must clearly articulate the basis of design for the building enclosure systems in the contract documents. By avoiding illustrating complicated details, or by omitting or illegibly illustrating the intent for air, water, vapor (as appropriate for the project conditions), and thermal barrier continuity, the designer of record handicaps the project’s chances for success.

Adjacent systems/substrates omitted

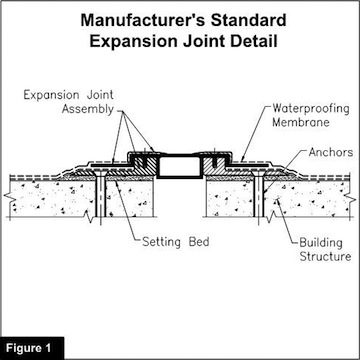

It is common for construction teams to submit enclosure shop drawings comprised solely of manufacturer’s standard product details without substrate identification and information on interfacing components. This practice is at best inefficient, requiring revisions and avoidable extra administrative time by the Building Team.

It is even more common that the installation proceeds on this basis without regard to project-specific conditions. Interface details are field-coordinated under the pressure of the construction schedule, and, when conflicts are identified, the solutions available to the Building Team are often limited, as products are already fabricated and installed.

Case Study: A multiunit residential project in Maryland included a building expansion joint within the plaza waterproofing system, including several horizontal-to-vertical transitions. The initial expansion joint submittal consisted of a manufacturer’s standard detail (Figure 1). The illustration did not show the geometry at the corner transitions or any of the interfacing materials. The construction team produced four iterations of shop drawing revisions, spanning several months, to arrive at the final version suitable for executing the work in the field.

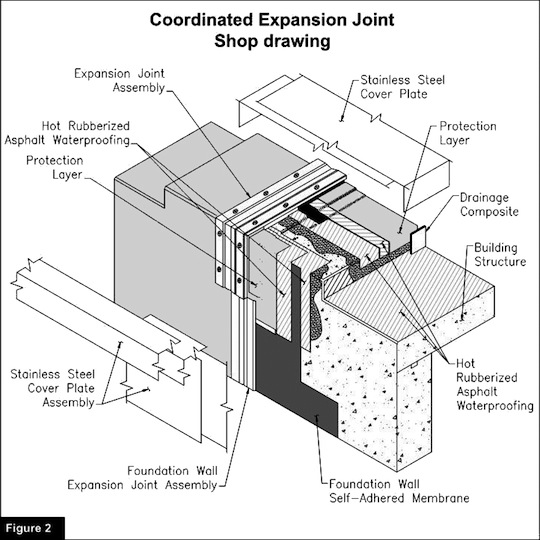

The Building Team certainly would rather have used the time spent generating and reviewing these revisions for other important tasks. How could they have collectively made better use of time? The design drawings should have highlighted the need for the expansion joint to traverse an outside corner. The construction team should have made an effort to anticipate the interfacing materials, establish a plan to execute the work on paper in advance of the construction, and include the necessary information in the initial version of the shop drawings; producing something similar to Figure 2.

Often, meetings among the affected contractors, manufacturers, and design team members can facilitate a critical review of the substrates and interfacing materials that must come together at these challenging details.

Adjacent Systems “By Others”

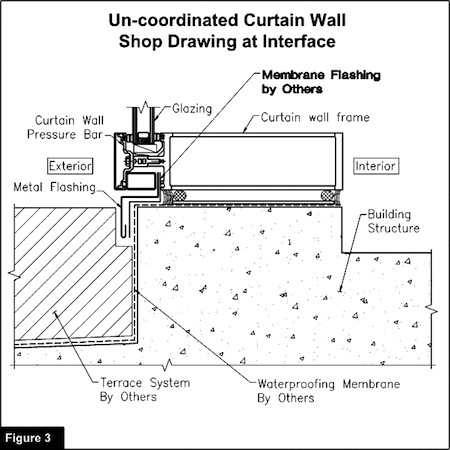

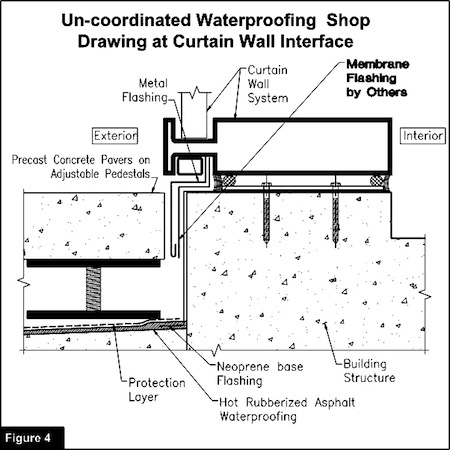

When building enclosure shop drawings do show adjacent enclosure components, they rarely do so accurately and are often adorned with the construction industry’s perilous “by others,” and installers are left to deal with the fallout resulting from the lack of coordination at interfaces between enclosure components.

Case Study: A high-rise building in Virginia included a glazed curtain wall adjacent to a terrace with hot-applied rubberized asphalt (HRA) waterproofing. The membrane flashing integration between the HRA base flashing and curtain wall sill was well illustrated in the contract documents.

Both the waterproofing contractor and glazing contractor prepared their own (otherwise satisfactory) shop drawing packages, and each included a version of this transition detail from their own perspectives (Figures 3 and 4). Both parties noted the membrane flashing integration as “by others.” Fortunately, the general and trade contractors identified this near miss shortly before installing terrace overburden that would have concealed the transition.

Near misses like this are not welcome on construction projects and tend to cause lost time and added effort by many parties. How could this situation have been avoided through a preconstruction coordination process? Similar to a MEP coordination drawings session, the affected contractors, manufacturers, and design team members could have met, overlaid the two versions of the transition detail, and asked “Who owns the membrane transition flashing?” and, subsequently, “Have we verified compatibility of all adjacent materials?” This exercise would have quickly facilitated the production of a coordinated, construction-ready shop drawing transition detail.

Conclusion

The building enclosure as a whole is no longer a combination of individual materials, but a holistic system with overall performance requirements that rely on the integration and coordination of building components to establish system continuity. Building enclosure shop drawings play a critical role in guarding against common performance, cost, and schedule pitfalls associated with the transitions between adjacent enclosure components. Building Teams can follow some basic guidelines to derive value from coordinated building enclosure shop drawings:

- Owners: Consider investing in Building Enclosure Commissioning (BECx) at a project's inception. BECx is a quality-assurance-focused process designed to verify that the Building Team is meeting the Owner’s project requirements. A BECx Agent is well positioned to help the Building Team manage the coordination challenges discussed above.

- Designers: Prepare design documents with clear designation for how the air, water, vapor (as appropriate for the project conditions), and thermal barriers transition between adjacent enclosure components to provide continuous building systems.

- Designers: Include a requirement for coordinated building enclosure shop drawings in the project specifications. Require singular, fully superimposed details (with regards to compatibility, performance, and constructability/sequencing) at each enclosure transition.

- Contractors: Submit building enclosure shop drawings that include substrate information, adjacent materials, flashings, sealants, and sequencing requirements that are coordinated between the affected trades and ready for execution in the field.

- Contractors: Understand that coordination of building enclosure systems is a critical aspect of improving building performance, managing risk, improving trade coordination and scheduling, and increasing trade contractor production.

About the Authors: John N. Karras and Jeffrey D. Kerr are with Simpson Gumpertz & Heger Inc.’s (SGH) Building Technology division in Washington, D.C. Both have diverse construction industry experience in construction management and building enclosure design, consulting, and investigation.

Related Stories

| Aug 11, 2010

Piano's 'Flying Carpet'

Italian architect Renzo Piano refers to his $294 million, 264,000-sf Modern Wing of the Art Institute of Chicago as a “temple of light.” That's all well and good, but how did Piano and the engineers from London-based Arup create an almost entirely naturally lit interior while still protecting the priceless works of art in the Institute's third-floor galleries from dangerous ultravio...

| Aug 11, 2010

Seven tips for specifying and designing with insulated metal wall panels

Insulated metal panels, or IMPs, have been a popular exterior wall cladding choice for more than 30 years. These sandwich panels are composed of liquid insulating foam, such as polyurethane, injected between two aluminum or steel metal face panels to form a solid, monolithic unit. The result is a lightweight, highly insulated (R-14 to R-30, depending on the thickness of the panel) exterior clad...

| Aug 11, 2010

Nurturing the Community

The best seat in the house at the new Seahawks Stadium in Seattle isn't on the 50-yard line. It's in the southeast corner, at the very top of the upper bowl. "From there you have a corner-to-corner view of the field and an inspiring grasp of the surrounding city," says Kelly Kerns, project leader with architect/engineer Ellerbe Becket, Kansas City, Mo.

| Aug 11, 2010

AIA Course: Historic Masonry — Restoration and Renovation

Historic restoration and preservation efforts are accelerating throughout the U.S., thanks in part to available tax credits, awards programs, and green building trends. While these projects entail many different building components and systems, façade restoration—as the public face of these older structures—is a key focus. Earn 1.0 AIA learning unit by taking this free course from Building Design+Construction.

| Aug 11, 2010

AIA Course: Enclosure strategies for better buildings

Sustainability and energy efficiency depend not only on the overall design but also on the building's enclosure system. Whether it's via better air-infiltration control, thermal insulation, and moisture control, or more advanced strategies such as active façades with automated shading and venting or novel enclosure types such as double walls, Building Teams are delivering more efficient, better performing, and healthier building enclosures.

| Aug 11, 2010

Glass Wall Systems Open Up Closed Spaces

Sectioning off large open spaces without making everything feel closed off was the challenge faced by two very different projects—one an upscale food market in Napa Valley, the other a corporate office in Southern California. Movable glass wall systems proved to be the solution in both projects.

| Aug 11, 2010

World's tallest all-wood residential structure opens in London

At nine stories, the Stadthaus apartment complex in East London is the world’s tallest residential structure constructed entirely in timber and one of the tallest all-wood buildings on the planet. The tower’s structural system consists of cross-laminated timber (CLT) panels pieced together to form load-bearing walls and floors. Even the elevator and stair shafts are constructed of prefabricated CLT.

| Aug 11, 2010

Platinum Award: The Handmade Building

When Milwaukee's City Hall was completed in 1896, it was, at 394 feet in height, the third-tallest structure in the United States. Designed by Henry C. Koch, it was a statement of civic pride and a monument to Milwaukee's German heritage. It was placed on the National Register of Historic Places in 1973 and designated a National Historic Landmark in 2005.

| Aug 11, 2010

Special Recognition: Kingswood School Bloomfield Hills, Mich.

Kingswood School is perhaps the best example of Eliel Saarinen's work in North America. Designed in 1930 by the Finnish-born architect, the building was inspired by Frank Lloyd Wright's Prairie Style, with wide overhanging hipped roofs, long horizontal bands of windows, decorative leaded glass doors, and asymmetrical massing of elements.