An emerging trend in Denver, and across the country, involves retrofitting older office buildings to make them more marketable to tenants, as well as more energy efficient and sustainable. One example transformed the Larimer Corporate Plaza, a 205,000-sf office building located in downtown Denver’s financial district. The project involved redesigning and reconstructing the eight-story building’s façade and remodeling all the common areas, along with making extensive upgrades to the building’s mechanical systems.

The Building Team of 17th & Larimer LLC (owner), Klipp Architects, and J.E. Dunn Construction (general contractor) selected Centria's Formawall Dimension Series to help achieve the retrofit project's goals of improved aesthetics, sustainability, and energy efficiency. “The goal was to give a facelift to a 1970s-style building,” said David Villella, Metal Walls Manager at A-1 Glass Inc., a Centria dealer/installer. “The addition of the Centria panels, along with new color and how these both complemented the glass on the structure, brought this building into the 21st century.”

The Building Team used 12,850 sf of the Formawall system on the facade, resulting in a fresh, welcoming, and modern aesthetic. Formawall is the only wall system that provides Centria's patented advanced thermal and moisture protection (ATMP) in a single panelized component. Compared to traditional multi-component wall construction, the Formawall Dimension Series is manufactured as one component.

“The existing precast façade was to remain, so the design team needed a new façade that was lightweight, so as not to exceed the capacity of the existing structure,” added Villella. “Metal was the perfect choice because of its design flexibility and light weight.” +

Related Stories

| Oct 3, 2011

Balance bunker and Phase III projects breaks ground at Mitsubishi Plant in Georgia

The facility, a modification of similar facilities used by Mitsubishi Heavy Industries, Inc. (MHI) in Japan, was designed by a joint design team of engineers and architects from The Austin Company of Cleveland, Ohio, MPSA and MHI.

| Sep 12, 2011

Living Buildings: Are AEC Firms up to the Challenge?

Modular Architecture > You’ve done a LEED Gold or two, maybe even a LEED Platinum. But are you and your firm ready to take on the Living Building Challenge? Think twice before you say yes.

| Jul 22, 2011

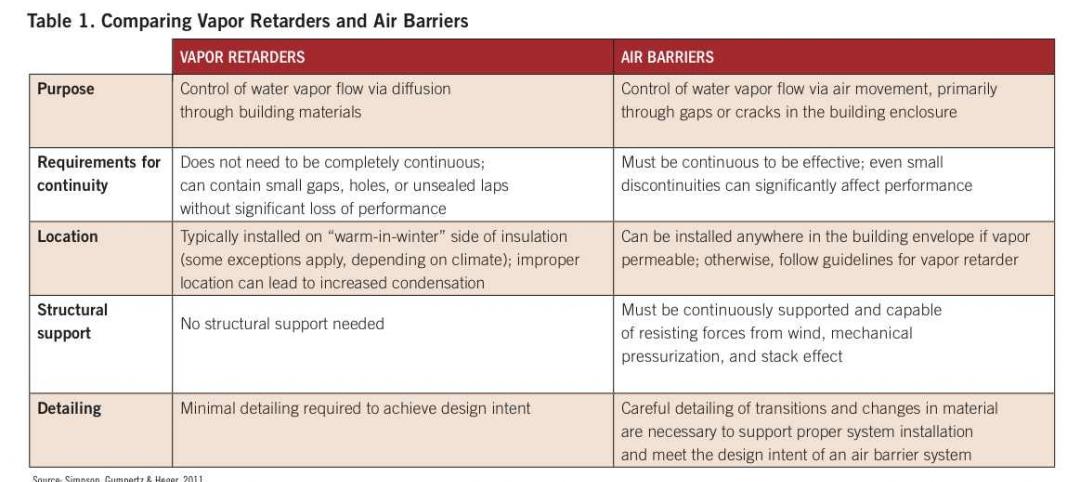

Air barrier systems: Your guide to optimal performance

Expert advice on how to control wasteful air leakage in the building envelope.

| Jul 22, 2011

Five award-winning modular innovations

The Modular Building Institute's 2011 Awards of Distinction highlight fresh ideas in manufactured construction projects.

| Oct 13, 2010

Community college plans new campus building

Construction is moving along on Hudson County Community College’s North Hudson Campus Center in Union City, N.J. The seven-story, 92,000-sf building will be the first higher education facility in the city.

| Aug 11, 2010

Morphosis builds 'floating' house for Brad Pitt's Make It Right New Orleans foundation

Morphosis Architects, under the direction of renowned architect and UCLA professor Thom Mayne, has completed the first floating house permitted in the U.S. for Brad Pitt’s Make It Right Foundation in New Orleans.The FLOAT House is a new model for flood-safe, affordable, and sustainable housing that is designed to float securely with rising water levels.