The new multimillion dollar, 22,000+ sq. ft. multipurpose YMCA community facility in Shelton, Washington, is a dream come true for Mason County residents—one that contributes to the community’s deeply held civic pride. With a stated goal of strengthening communities through healthyliving and social responsibility, the project owner—South Sound YMCA (a leading nonprofit) —set out to create a full-service, state-of-the-art community center in Shelton where people could come and enjoy a host of fitness amenities, including aquatics, camps, wellness workshops and other sports activities. The facility, which consists of five custom-engineered Star Building Systems buildings, opened its doors in March 2021,and features a gymnasium, locker rooms, cardio equipment, free weights, yoga and cycling studios, basketball and volleyball courts, in addition to a covered outdoor pool.

As reported by the Shelton-Mason County Chamber of Commerce (October 2020), Aubree Fudge, Senior Director of the Shelton Family YMCA branch emphasized that the center would serve as much more than a gym. The Chamber noted that Fudge “likened it to a community hub; a friendly outlet for physical, social and financial fitness … designed to be a safe, family-friendly destination that encourages mind-body balance and love for mankind.”

To achieve the project goals and create the ambitiously practical yet welcoming open space, the talented and innovative team of designers and erectors from Bahnmiller Construction Inc., a firm that specializes in pre-engineered metal building (PEMB), worked alongside Star Building Systems.

Product-wise, Star provided the pre-engineered framing (multi span building, double slope with tapered columns) and 22,437 sq. ft. of metal roof panels for the multiple roofs (singles and gables), which were Double-Lok® in Weathered Bronze, an earth tone hue selected to meet the owner’s preference. Perhaps most importantly, though, Star added its engineering expertise to help navigate the ins and outs of the challenging project.

In keeping with its overall mission to support its building partners throughout a project’s lifecycle, the Star team took tremendous pride in empowering Bahnmiller to advance its business through strong personal relationships and exemplary customer service, as well as comprehensive estimating tools and access to design tools and technology—in particular, providing the resources needed for a “do it yourself” approach.

David Verret, Project Manager and Estimator for Bahnmiller, explains that this was a design-build project right from the start, which gave them a good amount of time to do the planning with the architectural team and the structural team in order to make sure everything worked cohesively. He states, “The expectation of the owner was first and foremost about dollars. The project was originally designed as Glulam beam, and the decision was made early on to switch it to pre-engineered for cost efficiency. That’s where we got involved. We're a full-service pre-engineered supply and erector company. We specialize in high complexity, challenging projects. Those are the jobs that we're known for being successful on … and that we most enjoy.”

To that end, the biggest challenge on this project, according to Verret, was the profile of the building—the low eave and the spans. He shares, “The layout was not your typical 60- x 120-ft. pre-engineered building. This was made up of four or five building components and each building was offset from the other. And so, due to where the mainframes were located, we had to really try creative engineering to solve some of the structural challenges.”

Verret credits Bahnmiller Construction’s relationship with Star for blending and aiding in that creative process, providing a great advantage. “Star was flexible ... and not so flexible,” he muses, adding, “we're dealing with pre-engineered steel, which, no pun intended, is very rigid in the engineering process. But if it's managed and communicated correctly and you can have open communication, you can try to be creative with the engineering process. That's what Star did. They really stepped up and helped out with some of the serviceability issues with the architect's needs and translated those into a successful structure.”

The project consisted of multiple buildings with symmetrical 12’-6” eave heights and a 1/12 single slope 30-ft. low eave at the gym. Verret explains, “We ended up with about 6-ft. headroom after some of the rafters were engineered. That’s really where the creative design and engineering had to come in to take that 6-ft.-deep rafter and make it more functional, turning it into 2-1/2 or 3 feet.” Additionally, rigid insulation (R-Seal) at walls/multiple façade reveals and trims were used in conjunction with the Star products.

“The big thing,” says Verret,“was trying to deliver a pre-engineered building that allowed for mechanical and lighting engineers to put their products and their systems into it so that there was seamless coordination with the pre-engineered components. With Star’s help, we were able to achieve that goal. In the end, everyone involved appreciated the efforts and loves the building. The owner is excited to bring the multi-use facility to the community.”

In addition to being a community hub for connection, the Shelton YMCA received even further recognition by winning Star’s 2020 Builder’s Choice Master Builder of the Year award.

GC: FORMA Construction Co

Architect: Foster and William

Builder: Bahnmiller Construction, Inc.

Star Products:

Pre-engineered framing: Multi span building, double slope with tapered columns

Roof Panels: Double-Lok, Weathered Bronze, 22,437 square footage

Related Stories

Sponsored | Cladding and Facade Systems | Mar 15, 2023

Metal cladding trends and innovations

Metal cladding is on a growth trajectory globally. This is reflected in rising demand for rainscreen cladding and architectural metal coatings. This course covers the latest trends and innovations in the metal cladding market.

Codes | Mar 2, 2023

Biden Administration’s proposed building materials rules increase domestic requirements

The Biden Administration’s proposal on building materials rules used on federal construction and federally funded state and local buildings would significantly boost the made-in-America mandate. In the past, products could qualify as domestically made if at least 55% of the value of their components were from the U.S.

AEC Innovators | Feb 28, 2023

Meet the 'urban miner' who is rethinking how we deconstruct and reuse buildings

New Horizon Urban Mining, a demolition firm in the Netherlands, has hitched its business model to construction materials recycling. It's plan: deconstruct buildings and infrastructure and sell the building products for reuse in new construction. New Horizon and its Founder Michel Baars have been named 2023 AEC Innovators by Building Design+Construction editors.

Sponsored | Metals | Jan 16, 2023

Breaking The Mold: ALPOLIC MCM Accomplishes A+ Design for Ohio School

From the start, the vision for Dayton’s Northridge Local Schools included a standout architectural element. Taking inspiration from the polar bear mascot, Levin Porter Architects created an unforgettable iceberg feature with the help of ALPOLIC. Custom white MCM panels shimmer and provide a local landmark for the community.

75 Top Building Products | Nov 30, 2022

75 top building products for 2022

Each year, the Building Design+Construction editorial team evaluates the vast universe of new and updated products, materials, and systems for the U.S. building design and construction market. The best-of-the-best products make up our annual 75 Top Products report.

Sponsored | Metals | Nov 10, 2022

Largest Tulip Bulb Forcing Farm Rebuilds from Ground Up

Metl-Span insulated metal panels delivered the optimal solution for the new Pioneer Flower Farms facility to rebuild after a fire. The warehouse included the installation of movable freezers and cold storage areas.

Sponsored | Metals | Nov 9, 2022

Making a Difference: Lakeshore Lofts Brings Sustainability and Support with Inspiring Designs

Lakeshore Lofts sets a new standard for affordable housing providing expansive services and support and inspiring sustainable design made possible with ALPOLIC.

Building Materials | Nov 2, 2022

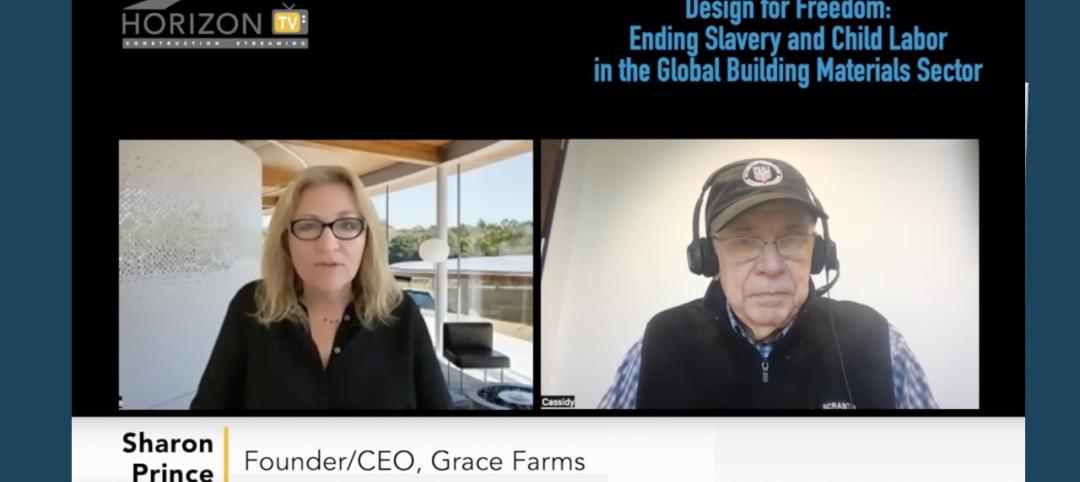

Design for Freedom: Ending slavery and child labor in the global building materials sector

Sharon Prince, Founder and CEO of Grace Farms and Design for Freedom, discusses DFF's report on slavery and enforced child labor in building products and materials.

Sponsored | Metals | Oct 13, 2022

The Benefits of Insulated Metal Panels Over Tilt-Up Walls

When it comes time to choose a building envelope material, project teams can select from a wide array of options. Tilt-up walls can offer some savings, but one system leads the industry for installation, energy, and cost efficiencies: Insulated metal panels.