Chicago-based Omega Yeast, the largest supplier of brewer’s yeast in the U.S., has recently moved to its new 13,800-sf production facilities after the company outgrew its former space.

The company purchased an existing building a block away from the original space, but during the renovation, Omega Yeast realized it was already outpacing this new space as well. The company then purchased the lots behind the Phase 1 building to further expand the operations across the alley and to build a new building tailored to the unique business needs.

Because it is located in a residential area, the loud production facilities were pushed to the back of the building while the quieter lab spaces, offices, and the break room were moved toward the residential street front. Lab spaces on the second floor have wrap-around windows that are elevated to face the Metra platform on the east side.

Adjacent to the eastern wall are large silos for spent grain and dry grain, one of which is painted in brand colors. By the alley on the north side, a small patio faces a large glazed opening that exposes the brewing facilities.

The company’s recent rebrand informed the look of the building with white brick, black and white corrugated metal, warm wood finishes, and “Omega Yeast Blue” highlighting the design.

The build team included Valerio Dewalt Train (architect), J.T. Magen & Company (general contractor), Calor Design Group (civil, fire protection, and MEP), and Klein & Hoffman (structural engineer).

Related Stories

Sponsored | | Jul 17, 2014

A major hop forward

The construction of efficient metal buildings has helped Perrault Farms expand its hops-harvesting business.

| Jul 14, 2014

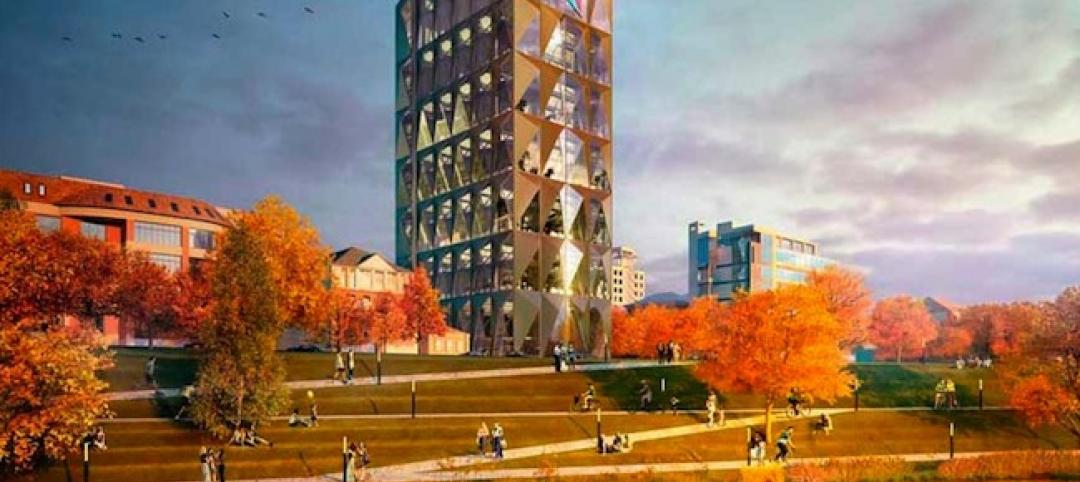

Foster + Partners unveils triple-glazed tower for RMK headquarters

The London-based firm unveiled plans for the Russian Copper Company's headquarters in Yekaterinburg.

| Jul 10, 2014

Berkeley Lab opens 'world's most comprehensive building efficiency simulator'

DOE’s new FLEXLAB is a first-of-its-kind simulator that lets users test energy-efficient building systems individually or as an integrated system, under real-world conditions.

| Jul 7, 2014

7 emerging design trends in brick buildings

From wild architectural shapes to unique color blends and pattern arrangements, these projects demonstrate the design possibilities of brick.

| Jul 2, 2014

Emerging trends in commercial flooring

Rectangular tiles, digital graphic applications, the resurgence of terrazzo, and product transparency headline today’s commercial flooring trends.

| Jun 30, 2014

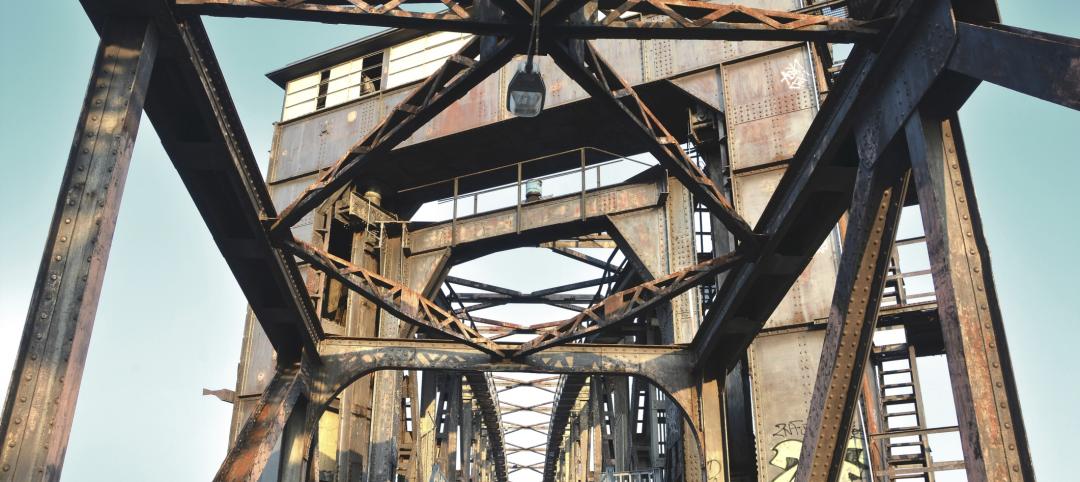

Report recommends making infrastructure upgrades a cabinet-level priority

The ASCE estimates that $3.6 trillion must be invested by 2020 to make critically needed upgrades and expansions of national infrastructure—and avoid trillions of dollars in lost business sales, exports, disposable income, and GDP.

Sponsored | | Jun 27, 2014

SAFTI FIRST Now Offers GPX Framing with Sunshade Connectors

For the Doolittle Maintenance Facility, SAFTI FIRST provided 60 minute, fire resistive wall openings in the exterior using SuperLite II-XL 60 insulated with low-e glazing in GPX Framing with a clear anodized finish.

| Jun 18, 2014

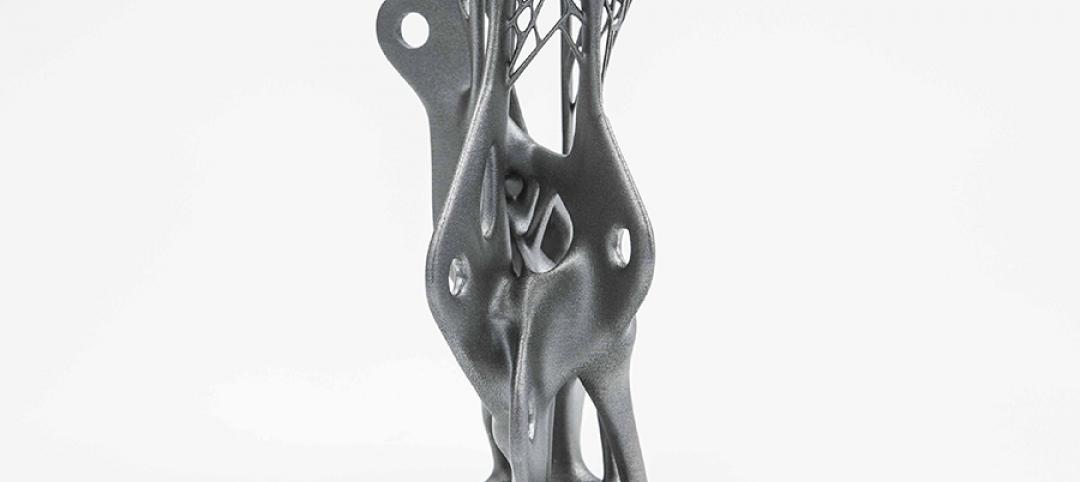

Arup uses 3D printing to fabricate one-of-a-kind structural steel components

The firm's research shows that 3D printing has the potential to reduce costs, cut waste, and slash the carbon footprint of the construction sector.

| Jun 16, 2014

6 U.S. cities at the forefront of innovation districts

A new Brookings Institution study records the emergence of “competitive places that are also cool spaces.”

| Jun 12, 2014

Austrian university develops 'inflatable' concrete dome method

Constructing a concrete dome is a costly process, but this may change soon. A team from the Vienna University of Technology has developed a method that allows concrete domes to form with the use of air and steel cables instead of expensive, timber supporting structures.