When Plaza Construction first introduced the concept of "core first" in managing the construction of a major office building, the procedure of pouring concrete prior to erecting a steel frame had never been done in New York City. The precedent-setting development was utilized to build Eleven Times Square, a 40-story, 1.1 million-sf office building in New York City, resulting in a tremendous savings, completion a couple of months ahead of schedule and with no major accidents.

It was designed according to LEED Gold specifications, and its owner, SJP Properties, claims that it is one of the safest and most efficient buildings in the world. Needless to say, this method is now considered standard in the building industry, but Eleven Times Square was the first in this market.

The concrete-first method had long been used in other markets and throughout Europe, but there was strong resistance to it by New York’s laborers, mainly because of safety concerns. The developers were able to get the labor unions to buy into the technique through proving that a safe worksite will be maintained—and by all reports—Eleven Times Square changed a lot of minds.

Eleven Times Square’s architectural features include floor plates that expand as the building rises, as well as six tenant-exclusive terraces on the tower. Seven column-free corner offices are available on every tower floor, with panoramic views of the Hudson River, Times Square, and the Empire State Building. The base floors are 41,000 sf each.

How do you build a concrete core ahead of-and completely independent of-the structural steel frame? Why is it advantageous to do so? According to Richard Wood, President and CEO of Plaza Construction, “it’s done by erecting a self-climbing form-a gigantic mold, in effect-on top of footings, with reinforced steel placed inside it. Concrete is poured into the form, and when it’s dried, hydraulics lift the form up to a new point, and the process is repeated.”

“Within the concrete,” Wood explains, “flush to the face of the form, are flat plates of steel with sheer tabs welded onto them, from the trailing platform after the form climbs, and bolt-holes creating the attachment for the beams that will follow. The trailing platforms are part and parcel of the structure of the forming system. As the system is hydraulically lifted, the platforms go along with them so they’re constantly climbing the building.”

At Eleven Times Square, the foundation contractor, Urban Foundation/Engineering, got started on the concrete core before the foundation was completed and while the steel was still in fabrication. Also involved were Sorbara Concrete, Cives Steel and Cornell Erectors. During this process, the steel framing followed as soon as the bottom of the climbing forms cleared the embedding. This tightly organized system allowed completion of the core in the shortest possible time.

“This system is advantageous because these forming systems allow you to better control the quality of concrete and the schedule of the pours are not dependent on other work,” Wood explains. “This concrete core is in essence a building unto itself, a well-protected and secure core area that serves multiple purposes. It creates the lateral stability of the structure and a safe zone, after occupancy, and provides for safe egress.”

The core encloses all the building’s critical elements, including extra-wide stairways, elevators, utility risers, and the building’s command center. Mechanical, electrical, and telecommunications rooms for each floor are fully enclosed within the core walls, which results in greater security and reduced noise.

Eleven Times Square was particularly suited to the core-first option and SJP Properties chose this method based on the configuration of the core: a straight–up configuration that was especially receptive to the self-climbing, forming system. PERI, a manufacturer that has subsidiaries in more than 50 countries, provided the climbing forms.

“The forms were customized for specific projects,” Wood concludes. “The forming system is not just the form itself, but the platform that the trades work from, plus storage for materials that are introduced into the sheer wall as it climbs vertically. The system creates a self-contained secure area.”

The concrete core was made of locally sourced material, and most of the reinforcing steel was recycled-thus boosting the building’s LEED rating considerably.

According to SJP, the unions, site safety experts, and subcontractors worked together to develop a comprehensive safety plan. Egress was a major issue, which was addressed via a dedicated hoist for the core construction and a temporary stair hanging from the formwork, which accessed multiple levels at any given time, giving direct access to the permanent stairs-which were installed immediately to the underside of the form system at each jump. Plaza also employed two full-time safety managers to simultaneously monitor the core and steel construction, and implemented a safety reward program for the trades.

The result is a core-first system that allows for cost-savings, speed and safety because the concrete is erected in an encased cocoon.

Related Stories

High-rise Construction | Feb 23, 2024

Designing a new frontier in Seattle’s urban core

Graphite Design Group shares the design for Frontier, a 540,000-sf tower in a five-block master plan for Seattle-based tech leader Amazon.

Construction Costs | Feb 22, 2024

K-12 school construction costs for 2024

Data from Gordian breaks down the average cost per square foot for four different types of K-12 school buildings (elementary schools, junior high schools, high schools, and vocational schools) across 10 U.S. cities.

MFPRO+ Special Reports | Feb 22, 2024

Crystal Lagoons: A deep dive into real estate's most extreme guest amenity

These year-round, manmade, crystal clear blue lagoons offer a groundbreaking technology with immense potential to redefine the concept of water amenities. However, navigating regulatory challenges and ensuring long-term sustainability are crucial to success with Crystal Lagoons.

Architects | Feb 21, 2024

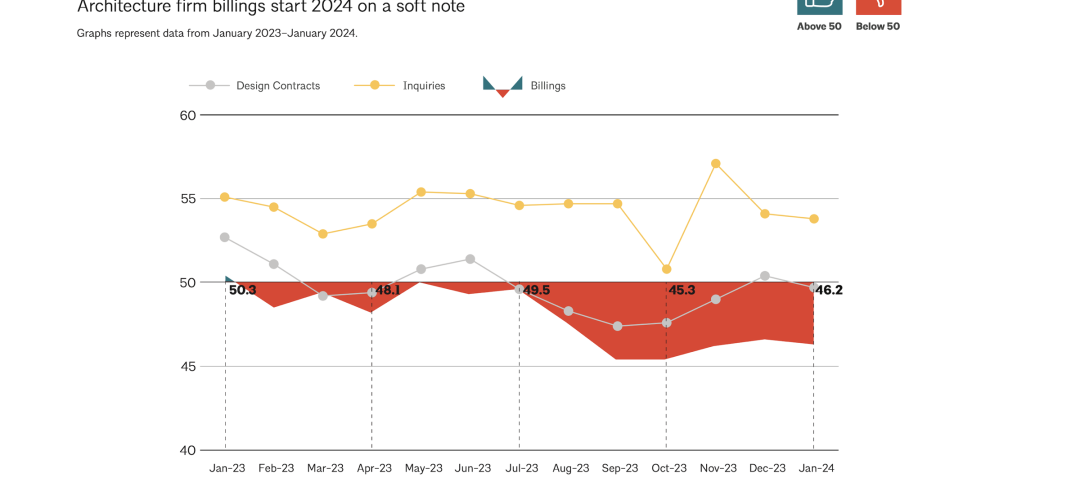

Architecture Billings Index remains in 'declining billings' state in January 2024

Architecture firm billings remained soft entering into 2024, with an AIA/Deltek Architecture Billings Index (ABI) score of 46.2 in January. Any score below 50.0 indicates decreasing business conditions.

University Buildings | Feb 21, 2024

University design to help meet the demand for health professionals

Virginia Commonwealth University is a Page client, and the Dean of the College of Health Professions took time to talk about a pressing healthcare industry need that schools—and architects—can help address.

AEC Tech | Feb 20, 2024

AI for construction: What kind of tool can artificial intelligence become for AEC teams?

Avoiding the hype and gathering good data are half the battle toward making artificial intelligence tools useful for performing design, operational, and jobsite tasks.

Engineers | Feb 20, 2024

An engineering firm traces its DEI journey

Top-to-bottom buy-in has been a key factor in SSOE Group’s efforts to become more diverse, equitable, and inclusive in its hiring, mentoring, and benefits.

Building Tech | Feb 20, 2024

Construction method featuring LEGO-like bricks wins global innovation award

A new construction method featuring LEGO-like bricks made from a renewable composite material took first place for building innovations at the 2024 JEC Composites Innovation Awards in Paris, France.

Codes and Standards | Feb 20, 2024

AISC, AIA release second part of design assist guidelines for the structural steel industry

The American Institute of Steel Construction and AIA Contract Documents have released the second part of a document intended to provide guidance for three common collaboration strategies.

Student Housing | Feb 19, 2024

UC Law San Francisco’s newest building provides student housing at below-market rental rates

Located in San Francisco’s Tenderloin and Civic Center neighborhoods, UC Law SF’s newest building helps address the city’s housing crisis by providing student housing at below-market rental rates. The $282 million, 365,000-sf facility at 198 McAllister Street enables students to live on campus while also helping to regenerate the neighborhood.