The School of Engineering at the University of Melbourne in Australia recently announced plans to build a new campus, to open in the early 2020s, that would feature large-scale research and training facilities to test emerging technologies that address global social and environmental issues.

One of those technologies is prefabrication for construction, and the university has taken a vanguard role to push prefabrication’s market share within the country’s construction industry to 15% by 2025, from 5% currently. That increase would represent around 20,000 new jobs and 30 billion Australian dollars (US$21.1 billion) in growth.

“We are seeing huge demand in the building industry for new techniques that will allow for the development of faster and cheaper construction. The only way to reduce costs is to reduce the cost of manufacturing,” says Tuan Ngo, director of the Advanced Protective Technologies for Engineering Structures Group within the university’s Department of Infrastructure Engineering.

It's not always easy to pinpoint a movement's breakthrough moments. But an online article that Deloitte posted on February 26 makes the case for a high-rise project in Melbourne, completed in 2010, that deployed a construction technique where entire floors of the building were completed offsite and assembled onsite by snapping together the modules one on top of the other.

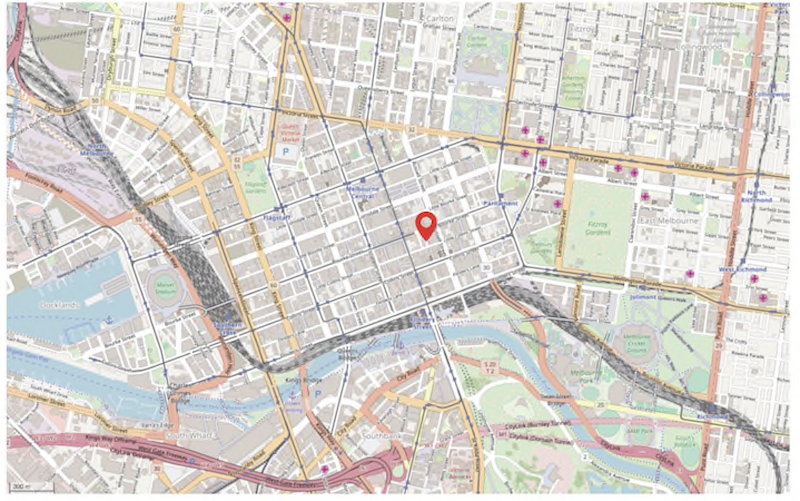

The location: Russell Place in Melbourne’s central business district. That real estate was problematic to build on because it sat over one of the district’s electrical substations. Weight restrictions limited the mass of any building constructed on the site, and ground vibration had to be minimized.

The land owner, a pre-eminent architect named Nonda Katsalidis, circumvented these roadblocks and restrictions by treating the construction process as a design-for-manufacture-and-assembly problem, rather than a building problem.

Russell Place, where the Little Hero building was assembled, sat over a primary electrical substation for Melbourne's central business district, which presented several construction limitations. Image: Deloitte Insights

Katsalidis’ twist on an already-established design-for-manufacturing technique was to “unitize” the building, so that each unit—in this case, each floor—was finished in a factory and then transported completed to the jobsite for quicker assembly, a la LEGO Duplo.

Executing this approach required making a digital model of the entire building, accurate to its light fittings, power sockets, washers, and door hinges. Deloitte’s authors called this BIM on steroids.

To pull this off, Katsalidis cofounded a technology company, Unitised Building in 2008, and partnered with a building firm Hickory Group to create the tooling required, and to develop and manipulate the models.

The Russell Place site was the first to host a building constructed with Unitised Building’s modular method. Completed in 2010, the building, called Little Hero, contains 63 one- and two-bedroom apartments and duplex penthouse residences, all of which sit atop seven retail shops, cafés, and restaurants. The unitized process not only complied with all of the site’s restrictions, but cut construction time by more than six months compared to a conventional approach: The eight-story building took only four weeks to erect, at a cost comparable to that of a conventional process.

Deloitte’s authors explain that what separated the unitized approach from conventional prefab modular design and construction at that time was that it was easier to customize, focused on mid- to high-rise construction, and allowed completed modules to be “snapped” together, in contrast to a kit of parts approach.

In addition, say the authors, unitization offered a new way to export BIM data. “It is possible for a firm to retain possession of the models and export only the instructions they generate, to guide the machines and workers in a remote contract manufacturing facility and the remote building site. The models are held domestically, where the engineering talent required to develop and maintain the IP in them is located.”

Deloitte’s authors note that unitization has since led to a larger discussion about different approaches to building as an activity. Rather than simply digitizing existing building practices … “we need to digitalize building by shifting the foundation of our operating model to a wholly different premise,” they wrote.

The unitized process sometimes requires improvisation, too. In 2017, Hickory Group was working on a site within Melbourne’s central business district where access was awkward. The crane that was needed to lift building units into place blocked a narrow laneway, making it difficult for local residents to access their properties.

To navigate the problem, the firm offered to build only at night. To prove this approach to skeptical a city council and residents, Hickory ran a trial build one night, which went unnoticed despite the firm warning nearby residents about it beforehand. With the council and residents convinced that installing building units at night would work, construction went ahead.

King 25, Australia's tallest timber building, was assembled using prefabricated engineered wood components. Image: Wonderful Engineering

Whatever success Unitised Building and other companies may have had, it remains to be seen whether prefab construction can get beyond the nascent stage in Australia.

Prefab, as a concept, got a boost when Australia’s tallest timber building, the 10-story 45-meter-tall (148-ft-tall) 25 King, an office and residential tower in Brisbane, opened earlier this month. Designed by the architectural firm Bates Smart, the building’s engineered-wood components were prefabricated offsite. The entire construction took 15 months to complete.

But supply and demand are still in question. One one hand, Strongbuild, which made prefab houses from an 8,000-sm (86,111-sf) factory in Sydney, last November lost a AUD$45 million contract and went into voluntary “administration,” Australia’s version of liquidation.

On the other hand, David Chandler, a former builder who is now adjunct professor in construction management at Western Sydney University, told the Australian Financial Review that the country could lose up to 200,000 construction jobs to offshore competition if it doesn’t set up a viable prefab construction industry within the next decade.

Related Stories

| Aug 11, 2010

Sika Sarnafil launches sustainable roofing resource website SustainabilityThatPays.com

Sika Sarnafil, the worldwide market leader in thermoplastic roofing and waterproofing membranes, today launched a new web site dedicated to supporting sustainability principals and environmentally responsible building. The streamlined site, SustainabilityThatPays.com &http://www.SustainabilityThatPays.com> provides the building owner with critical information on selecting roofing and waterproofing systems...

| Aug 11, 2010

Prism-shaped design unveiled for five-star hotel in Saudi Arabia

Goettsch Partners has been commissioned by Saudi Oger Ltd. to design a new five-star, 214-key business hotel in the King Abdullah Financial District in Riyadh, Saudi Arabia. As a design-build assignment, Saudi Oger is serving as the contractor, selected by developer Rayadah Investment Company. The project is sited on Parcel 1.08, one of the first 10 parcels currently under development in the massive new master-planned district.

| Aug 11, 2010

Data center construction costs are down, according to a study by Environmental Systems Design

The current economic crisis has an up-side for owners of mission-critical facilities: On average, it costs less today to construct a new data center than it did in late 2007, according to a study by Environmental Systems Design (ESD). ESD found that the prices of feeder and cable have dropped by more than half, major data center equipment by 12%, labor and materials by 19.6%, and shipping and handling by 15% from the fourth quarter of 2007 to July 15, 2009.

| Aug 11, 2010

9 rooftop photovoltaic installation tips

The popularity of rooftop photovoltaic (PV) panels has exploded during the past decade as Building Teams look to maximize building energy efficiency, implement renewable energy measures, and achieve green building certification for their projects. However, installing rooftop PV systems—rack-mounted, roof-bearing, or fully integrated systems—requires careful consideration to avoid damaging the roof system.

| Aug 11, 2010

USGBC’s Greenbuild 2009 brings global ideas to local main streets

Save the planet with indigenous knowledge. Make permanent water part of your life. Dive deep water for clues to environmental success. Connect site selection to successful creative concepting. Explore the unknown with Discovery Channel’s best known guide. These are but a few of the big ideas participants can connect to at USGBC’s Greenbuild International Conference and Expo, taking place on November 11-13, 2009 in Phoenix, Ariz.