Global engineering and design consultantcy Arup launched "Rethinking the Factory," a report exploring the emerging trends, processes, and technologies that are transforming the manufacturing landscape. The report examines how the introduction of new technologies such as 3D printing, self-cleaning and self-healing materials, human/robot collaboration will lead to faster, more efficient and environmentally friendly production.

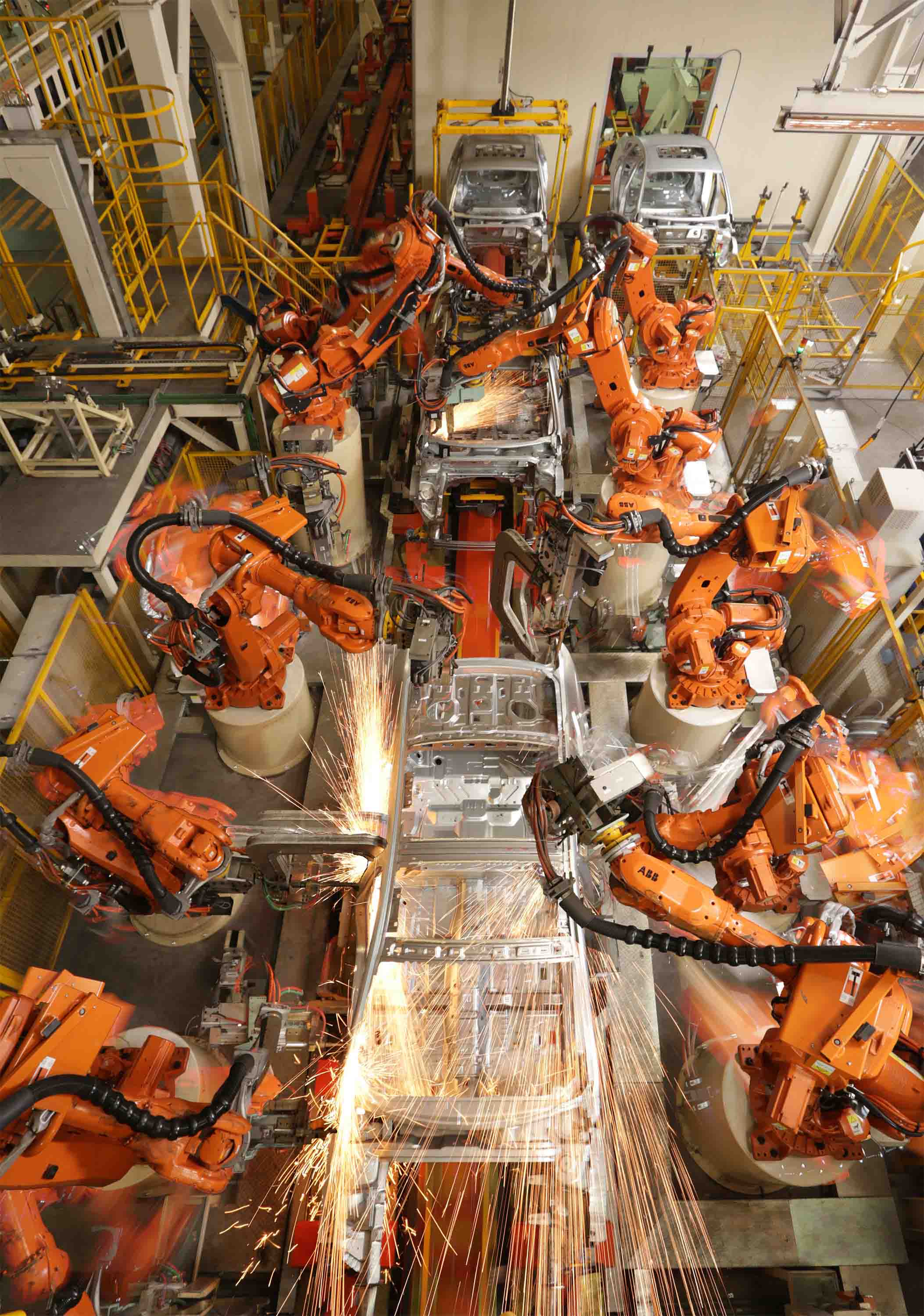

While many believe robots will replace humans in the factories of the future, the report, developed by Arup’s Foresight + Research + Innovation and Science and Industry teams, suggests collaboration between the two will be key. The integration of cameras and smart sensors already allow robots to adapt to their external environments.

Increasingly intuitive, their ability to infer a full task after being shown just a portion of it will enable workers to serve as robot supervisors, operating machinery and controlling smart production processes such as program and systems management and data analysis, rather than participating in manual labor. The increasing technicality of factories will mean that employees with STEM[1] skills will be particularly sought after, further exacerbating the international shortage of highly skilled workers, set to reach 40 million by 2020.

Beyond machines, new materials have the potential to improve the production process and increase product performance. A variety of self-healing and self-cleaning materials are being developed—such as bio-inspired plastic, which replicate the strength, durability, and versatility of a natural insect cuticles—which are capable of repairing damage without human intervention. These technologies will extend the lifetime of manufactured goods and reduce demand for raw materials.

Big data, technology, and 3D printing

The utilization of 3D printing—or more accurately, additive manufacturing—will allow manufacturing to be more mobile and dispersed. Factory locations are therefore likely to become both more varied and closer to the consumer, including the emergence of nontraditional spaces such as small offices in a city center. This will allow production to take place closer to the point of use, lowering transport costs and emissions.

Intelligence based on Big Data, advanced analytics, and the Internet of Things will create new opportunities for competitive advantage. Analysis of data will reveal detailed customer insights, identify new product opportunities sooner, and get new products and designs to market faster. Additive manufacturing and digital technologies will also make this mass customisation, faster, easier and more affordable.

Resilient and Adaptive Spaces

Flexibility will be critical to tackling changing consumer demands and shifting market trends. Factories will be adaptable, with modular building techniques to enable efficient re-scaling and diversification of production across various locations. This will also allow energy, water, and material consumption to be managed more effectively in an increasingly constrained resource market, while producing an environment best suited to meet the multiple needs of its highly skilled workforce.

Using tools such as BIM in factory design, planning and management will play a critical role in allowing manufacturers to foresee and mitigate issues based on access to resources, location choices, weather risks and transportation needs.

The design of the factory will also be more focused on consumer experience, utilising the factory as a showroom. The concept of the "transparent factory" will gain increased importance as more people get involved in making products or as they expect closer insight into how products are manufactured, especially at a customised level. The opportunity for factory owners and operators lies in adapting their existing spaces to enable these types of experiences to take place.

“The convergence of the physical and digital worlds means that manufacturers have to continue to adapt and adopt new processes quicker than ever before," Duncan White, Science and Industry Leader at Arup said in a press release. "While developing sustainable and resilient practices will be essential, having access to a skilled pool of workers will prove to be equally important and challenging as these changes are made. As such, it is critical that companies and policy-makers have a comprehensive understanding of the changing manufacturing landscape."

Rethinking the Factory is part of Arup’s Future of… series that envisages the possible futures by highlighting innovations from around the world. Previous reports include the Future of Highways, Future of Rail, Cities Alive, and It’s Alive.

For further information on Rethinking the Factory please download the report.

Related Stories

AEC Innovators | Apr 26, 2024

National Institute of Building Sciences announces Building Innovation 2024 schedule

The National Institute of Building Sciences is hosting its annual Building Innovation conference, May 22-24 at the Capital Hilton in Washington, D.C. BI2024 brings together everyone who impacts the built environment: government agencies, contractors, the private sector, architects, scientists, and more.

BIM and Information Technology | Mar 11, 2024

BIM at LOD400: Why Level of Development 400 matters for design and virtual construction

As construction projects grow more complex, producing a building information model at Level of Development 400 (LOD400) can accelerate schedules, increase savings, and reduce risk, writes Stephen E. Blumenbaum, PE, SE, Walter P Moore's Director of Construction Engineering.

AEC Tech | Mar 9, 2024

9 steps for implementing digital transformation in your AEC business

Regardless of a businesses size and type, digital solutions like workflow automation software, AI-based analytics, and integrations can significantly enhance efficiency, productivity, and competitiveness.

AEC Tech | Feb 28, 2024

How to harness LIDAR and BIM technology for precise building data, equipment needs

By following the Scan to Point Cloud + Point Cloud to BIM process, organizations can leverage the power of LIDAR and BIM technology at the same time. This optimizes the documentation of existing building conditions, functions, and equipment needs as a current condition and as a starting point for future physical plant expansion projects.

AEC Innovators | Feb 28, 2024

How Suffolk Construction identifies ConTech and PropTech startups for investment, adoption

Contractor giant Suffolk Construction has invested in 27 ConTech and PropTech companies since 2019 through its Suffolk Technologies venture capital firm. Parker Mundt, Suffolk Technologies’ Vice President–Platforms, recently spoke with Building Design+Construction about his company’s investment strategy.

AEC Tech | Jan 24, 2024

4 ways AEC firms can benefit from digital transformation

While going digital might seem like a playground solely for industry giants, the truth is that any company can benefit from the power of technology.

AEC Tech | Jan 8, 2024

What's driving the surge of digital transformation in AEC today?

For centuries, the AEC industry has clung to traditional methods and legacy processes—seated patterns that have bred resistance to change. This has made the adoption of new technologies a slow and hesitant process.

Digital Twin | Jul 31, 2023

Creating the foundation for a Digital Twin

Aligning the BIM model with the owner’s asset management system is the crucial first step in creating a Digital Twin. By following these guidelines, organizations can harness the power of Digital Twins to optimize facility management, maintenance planning, and decision-making throughout the building’s lifecycle.

Digital Twin | Jul 17, 2023

Unlocking the power of digital twins: Maximizing success with OKRs

To effectively capitalize on digital twin technology, owners can align their efforts using objectives and key results (OKRs).

Office Buildings | Jun 5, 2023

Office design in the era of Gen Z, AI, and the metaverse

HOK workplace and interior design experts Kay Sargent and Tom Polucci share how the hybrid office is evolving in the era of artificial intelligence, Gen Z, and the metaverse.