More than two decades into the building information modeling movement, AEC firms are still discovering ways to utilize BIM/VDC tools more effectively. One major current area of focus is how to cut waste in the BIM implementation process.

Inefficient virtual coordination meetings, cumbersome BIM files, and a “rush to model” mentality are just some of the profit-eating miscues that are commonplace in the AEC industry.

We reached out to several BIM/VDC power users for their top tips for eliminating waste in BIM/VDC workflows. Here’s what they said:

1. Recognize the importance of ‘tribal knowledge’

Many large, corporate AEC firms operate their BIM-driven projects like a manufacturing production line, with staff assigned to specific roles—design specialists, production experts, and construction administration specialists, all of whom move from project to project as they finish their piece of the BIM puzzle.

While efficient in theory, this Henry Fordish workflow model ultimately leads to waste and added costs, says Thom Chuparkoff, AIA, LEED AP, Associate with Populous. The problem, he says, lies in the turnover of staff during the transitions from design to documentation. At each transition, as certain staff members exit the project and others enter, the design team loses a bit of its “tribal knowledge”—its sense of knowing where a project came from and where it’s going, says Chuparkoff. Consistency of the team throughout the design and documentation phases is absolutely critical, he adds.

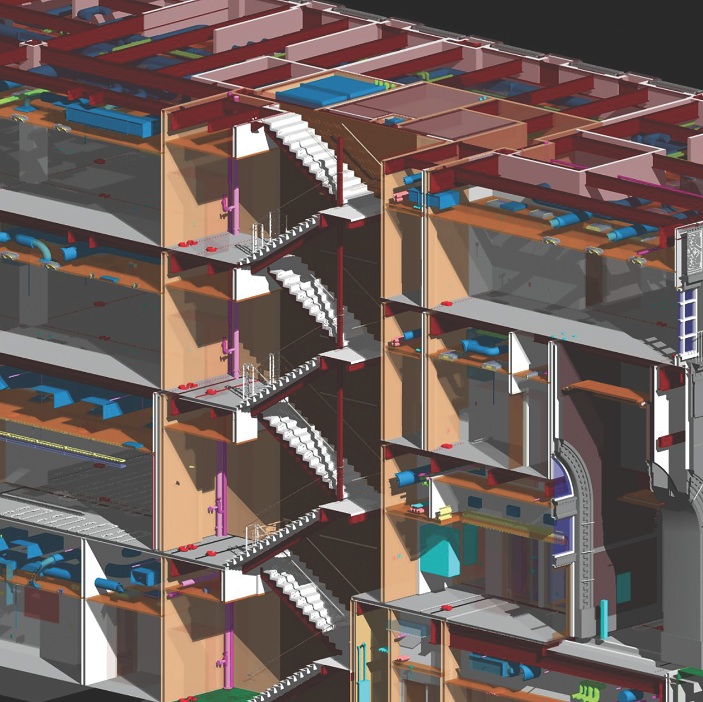

By employing basic process-mapping techniques at the outset of projects, Building Teams can reduce the amount of BIM modeling required on a project and develop models that offer increased value for the team and the client, says John Haymaker, PhD, AIA, LEED AP, Director of Research with Perkins+Will. Illustration: John Haymaker, Georgia Institute of Technology

“It’s troublesome to have, say, five people on the production team, none of whom had anything to do with the design,” says Chuparkoff. “They’re scratching their heads wondering why something was done the way it was. With construction schedules getting shorter, design teams don’t have time to go back and try to figure out what another team member was thinking.”

2. Master the art of the BIM coordination meeting

BIM/VDC tools are great, but if you can’t run efficient, productive coordination meetings, the Building Team will never realize the benefits of true BIM coordination. Gensler Project Architect and BIM/VDC expert Jared Krieger, AIA, LEED AP, recommends the following tips for making the most of virtual coordination meetings:

Practice and prepare. It takes skill to be able to navigate the project model and have the correct model views loaded and visibility settings adjusted for a meeting. Make the most of everyone’s time by allocating at least 15 minutes prior to each coordination meeting for one team member to load the model and specific views.

Assign a “designated driver,” someone who knows the model and is savvy about the software platform. Models can be cumbersome to navigate. Suffering through an inexperienced person trying desperately to steer the model will absolutely kill the momentum and productivity of the meeting.

“We often bypass conceptual 3D modeling software by encouraging the use of other mediums, such as clay and digital sketch models.”

—Thom Chuparkoff, AIA, LEED AP

Consider splitting meetings. Keep meetings focused on small components of the project, and include only the team members directly involved. Consider splitting meetings by profession. For example, meet with the structural engineer first to review structural-specific coordination. Then, have some overlap time with MEP and structural for common coordination. Finish the meeting with MEP coordination.

Use meeting notes to stay focused. Open action items and homework from the previous meeting should be the basis for discussion in your next meeting. Use this structure to keep your team on track, and resolve open coordination issues before moving on to new items.

3. Avoid double modeling whenever you can

Even with all the high-tech design and sketching tools available to designers, Chuparkoff advocates for a pen-and-paper approach to working with clients on early design concepts. He argues that firms allocate too much of their precious resources to creating overly complex 3D conceptual models, which then have to be painstakingly re-created in a BIM environment.

“At some firms, people will spend 40 hours or more building three different project models in SketchUp,” he says. “You don’t need three fully baked ideas, fully modeled, to present to the client. You need five or six good ideas, and not necessarily modeled. We often bypass conceptual 3D modeling software by encouraging the use of other mediums, such as clay and digital sketch models, early on to develop and refine ideas to the point where they can be modeled in BIM for the client one time. Before you get into the hard-line modeling, try to vet as much as you can the good old-fashioned way.”

4. Map your processes

AEC professionals have been trained to jump right in and start building the model. But this “rush to model” mentality often leads to inefficiencies, waste, and less-than-ideal models, says John Haymaker, PhD, AIA, LEED AP, Director of Research with Perkins+Will.

Haymaker, Assistant Professor of Architecture and Building Construction at Georgia Tech, recommends the use of process-mapping techniques—including value stream mapping and business process modeling—at the project outset to identify the decisions that need to be made during the design process, as well as the processes required to make those decisions. When done well, process mapping can help reduce the amount of BIM modeling required on a project and also lead to models that offer increased value for the team and the client, says Haymaker.

“For example, if an architect, mechanical engineer, and contractor can get together to map out their process for performing preliminary energy and cost analysis, the architect may realize that they only need to model spaces and exterior surfaces,” says Haymaker. “This would greatly simplify their modeling effort, and potentially eliminate useless or inaccurate data.”

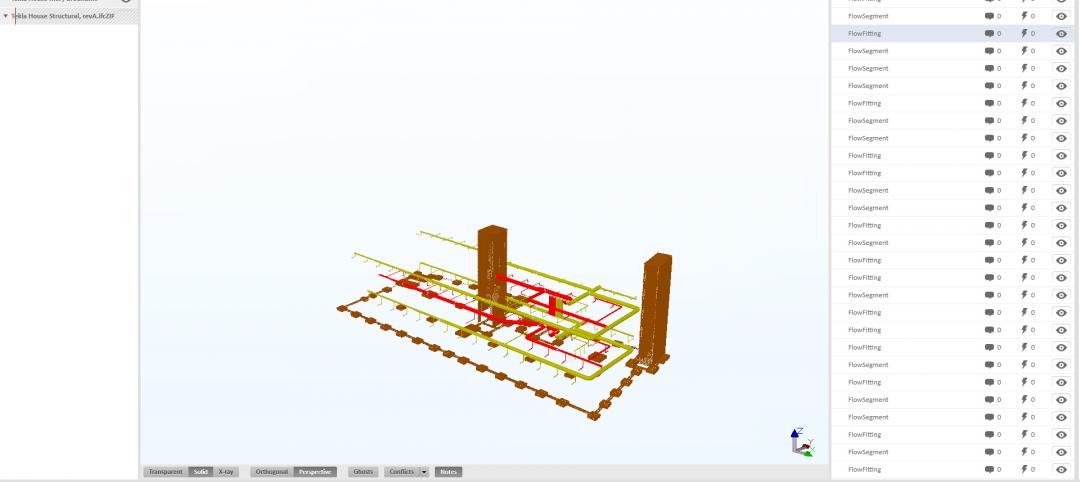

5. Divvy up the model to avoid unwieldy file sizes

Four years into the Tysons Tower project in Tysons Corner, Va., Gensler’s Krieger has just one minor regret: not managing the size of the BIM file more effectively. “Our model is pretty big, and even with great computers, it can become a bit of a bear at times when all the pieces are loaded in,” he says.

Working with a central BIM model has its benefits—notably, having a single repository for all project information. But on large, complex projects, BIM files can become ponderous, resulting in longer load times during virtual coordination meetings.

Splitting the model into chunks is one approach to managing the file size. “We try to think of logical pieces to keep as separate models,” says Krieger. “For example, if you have a tall building with a podium, you can keep the tower and podium as separate models and reference them into each other as needed. Or, on a building project with a complicated skin, you can keep the curtain wall as a separate model. The earlier you plan the split the better.”

Krieger also advises Building Teams to take note of the file size of BIM object families used on projects. Complicated projects can incorporate more than a thousand families, and some sets can exceed 10 megabytes in size. “We are very careful about how complicated and large the families can get,” he says.

6. Make sure someone ‘owns’ your companywide BIM/VDC standard

Given the rapid pace of change and innovation in the BIM/VDC software industry, it is imperative that AEC firms designate an in-house power user to maintain and update the company BIM/VDC standard.

“These tools are constantly evolving, and the company standard needs to evolve with them,” says Adam Lasota, Junior Architect with Rietveld Architects, New York. “Newer functions and features can make company standards obsolete, so it’s a matter of productivity.”

7. Create a simple BIM execution plan—and stick to it

Setting expectations and staying organized can be addressed through a simple, straightforward BIM execution plan that covers everything from schedule and roles to model sharing and level of development.

“It’s absolutely worth the effort,” says Gensler’s Krieger, referring to the firm’s work setting up an execution plan for Tysons Tower. “All the time we spent setting up views, sheet templates, and detail organization in the beginning is paying off in the construction administration process.”

When in the thick of a large, multi-year project, it’s easy for a team to stray from the original BIM execution plan. Fight that urge, because doing so can save thousands, perhaps millions, of dollars in avoided costs during construction.

“The biggest payoff has come from our team’s early commitment to have weekly BIM coordination sessions throughout the design process,” says Krieger. “It has resulted in a low number of RFIs and very few significant field coordination issues.”

Related Stories

| Feb 14, 2011

Sustainable Roofing: A Whole-Building Approach

According to sustainability experts, the first step toward designing an energy-efficient roofing system is to see roof materials and systems as an integral component of the enclosure and the building as a whole. Earn 1.0 AIA/CES learning units by studying this article and successfully completing the online exam.

| Feb 11, 2011

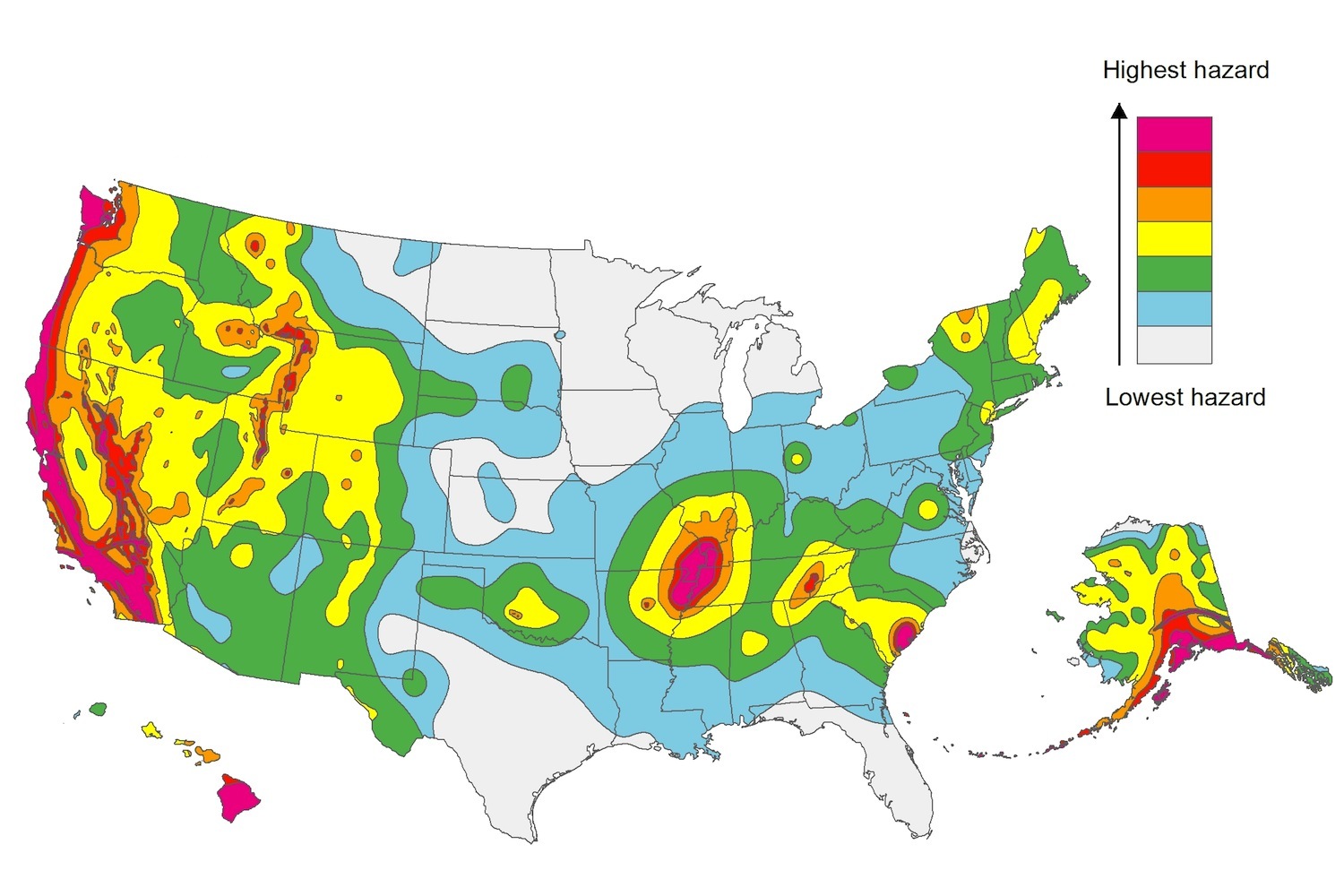

Four Products That Stand Up to Hurricanes

What do a panelized wall system, a newly developed roof hatch, spray polyurethane foam, and a custom-made curtain wall have in common? They’ve been extensively researched and tested for their ability to take abuse from the likes of Hurricane Katrina.

| Feb 11, 2011

RS Means Cost Comparison Chart: Office Buildings

This month's RS Means Cost Comparison Chart focuses on office building construction.

| Feb 11, 2011

Sustainable features on the bill for dual-building performing arts center at Soka University of America

The $73 million Soka University of America’s new performing arts center and academic complex recently opened on the school’s Aliso Viejo, Calif., campus. McCarthy Building Companies and Zimmer Gunsul Frasca Architects collaborated on the two-building project. One is a three-story, 47,836-sf facility with a grand reception lobby, a 1,200-seat auditorium, and supports spaces. The other is a four-story, 48,974-sf facility with 11 classrooms, 29 faculty offices, a 150-seat black box theater, rehearsal/dance studio, and support spaces. The project, which has a green roof, solar panels, operable windows, and sun-shading devices, is going for LEED Silver.

| Feb 11, 2011

BIM-enabled Texas church complex can broadcast services in high-def

After two years of design and construction, members of the Gateway Church in Southland, Texas, were able to attend services in their new 4,000-seat facility in late 2010. Located on a 180-acre site, the 205,000-sf complex has six auditoriums, including a massive 200,000-sf Worship Center, complete with catwalks, top-end audio and video system, and high-definition broadcast capabilities. BIM played a significant role in the building’s design and construction. Balfour Beatty Construction and Beck Architecture formed the nucleus of the Building Team.

| Feb 11, 2011

Kentucky’s first green adaptive reuse project earns Platinum

(FER) studio, Inglewood, Calif., converted a 115-year-old former dry goods store in Louisville, Ky., into a 10,175-sf mixed-use commercial building earned LEED Platinum and holds the distinction of being the state’s first adaptive reuse project to earn any LEED rating. The facility, located in the East Market District, houses a gallery, event space, offices, conference space, and a restaurant. Sustainable elements that helped the building reach its top LEED rating include xeriscaping, a green roof, rainwater collection and reuse, 12 geothermal wells, 81 solar panels, a 1,100-gallon ice storage system (off-grid energy efficiency is 68%) and the reuse and recycling of construction materials. Local firm Peters Construction served as GC.

| Feb 11, 2011

Former Richardson Romanesque hotel now houses books, not beds

The Piqua (Ohio) Public Library was once a late 19th-century hotel that sat vacant and deteriorating for years before a $12.3 million adaptive reuse project revitalized the 1891 building. The design team of PSA-Dewberry, MKC Associates, and historic preservation specialist Jeff Wray Associates collaborated on the restoration of the 80,000-sf Richardson Romanesque building, once known as the Fort Piqua Hotel. The team restored a mezzanine above the lobby and repaired historic windows, skylight, massive fireplace, and other historic details. The basement, with its low ceiling and stacked stone walls, was turned into a castle-like children’s center. The Piqua Historical Museum is also located within the building.

| Feb 11, 2011

Justice center on Fall River harbor serves up daylight, sustainable elements, including eucalyptus millwork

Located on historic South Main Street in Fall River, Mass., the Fall River Justice Center opened last fall to serve as the city’s Superior and District Courts building. The $85 million facility was designed by Boston-based Finegold Alexander + Associates Inc., with Dimeo Construction as CM and Arup as MEP. The 154,000-sf courthouse contains nine courtrooms, a law library, and a detention area. Most of the floors have the same ceiling height, which will makes them easier to reconfigure in the future as space needs change. Designed to achieve LEED Silver, the facility’s elliptical design offers abundant natural daylight and views of the harbor. Renewable eucalyptus millwork is one of the sustainable features.