In desert climates, extreme heat and dry air are not just uncomfortable, they can be life-threatening. Virginia San Fratello and Ronald Rael of The Emerging Objects Corporation may have found a natural cooling solution for increased safety and comfort in arid areas.

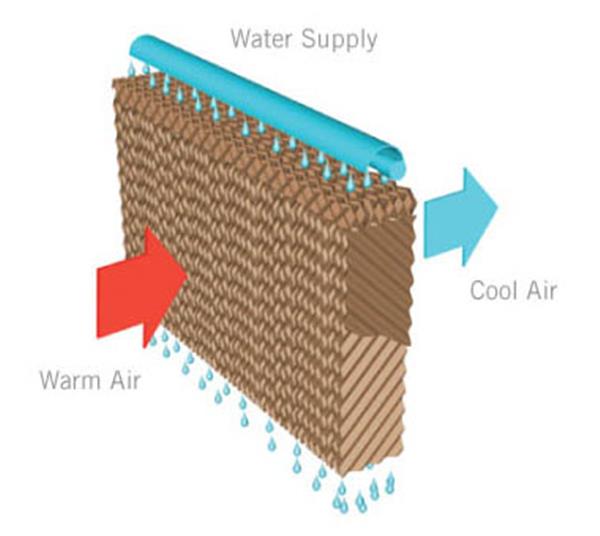

Evaporative cooling is the process of adding water to the air, causing the temperature to drop, and increasing the moisture in the air, 3ders reports. The technique itself is ancient, but San Fratello and Rael have applied it to a 3D-printed brick prototype, called Cool Brick.

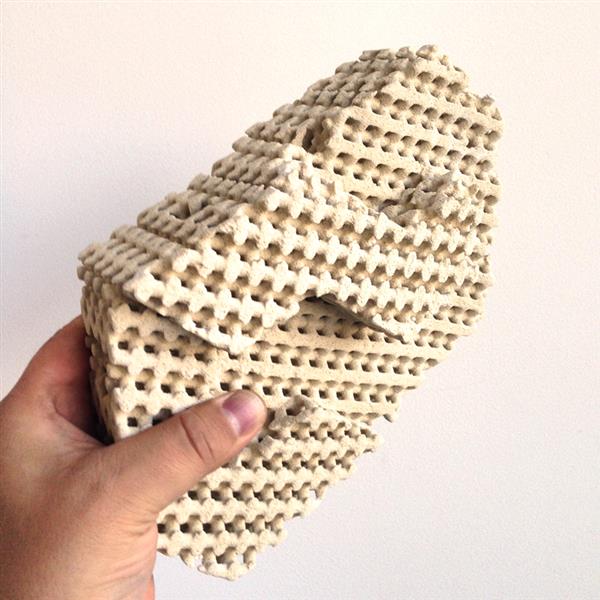

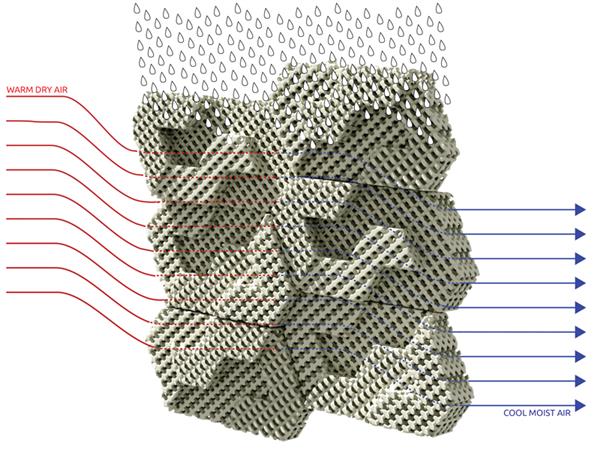

The prototype was inspired by the Muscatese Evaporative cooling window, a system that combines a wood screen and a ceramic vessel filled with water. The Cool Brick is made of porous ceramic bricks set in mortar. The bricks absorb water and are designed as 3D lattices that allow air to pass through the wall.

The water held in the micropores of the ceramic bricks evaporates as air moves through the system, bringing cool air into the building interior. This process results in cool, moist air while using less energy than other cooling techniques.

The Cool Bricks are modular and interlocking, meaning that they can be assembled as needed for the particular space where they’re installed. The lattice structure creates a tight bond when set in mortar. Meanwhile, the shape of the brick creates a shaded surface on the wall, keeping that portion of the wall cool.

The Cool Brick can be viewed at Data Clay: Digital Strategies for Parsing the Earth until April 19, 2015, at the San Francisco Museum of Craft and Design. Tehton 3D, a 3D printing company that specializes in custom applications for ceramic 3D printing, sponsored the project.

Related Stories

| Oct 6, 2011

GREENBUILD 2011: Growing green building market supports 661,000 green jobs in the U.S.

Green jobs are already an important part of the construction labor workforce, and signs are that they will become industry standard.

| Oct 5, 2011

GREENBUILD 2011: Brick offers growing options for sustainable building design

Brick exteriors, interiors and landscaping options can increase sustainability that also helps earn LEED certification.

| Oct 4, 2011

GREENBUILD 2011

Click here for the latest news and products from Greenbuild 2011, Oct. 4-7, in Toronto.

| Oct 4, 2011

GREENBUILD 2011: Methods, impacts, and opportunities in the concrete building life cycle

Researchers at the Massachusetts Institute of Technology’s (MIT) Concrete Sustainability Hub conducted a life-cycle assessment (LCA) study to evaluate and improve the environmental impact and study how the “dual use” aspect of concrete.

| Oct 3, 2011

Magellan Development Group opens Village Market in Chicago’s Lakeshore East neighborhood

Magellan Development Group and Hanwha Engineering & Construction are joint-venture development partners on the project. The Village Market was designed for Silver LEED certification by Loewenberg Architects and built by McHugh Construction.

| Sep 29, 2011

Busch Engineering, Science and Technology Residence Hall opens to Rutgers students

With a total development cost of $57 million, B.E.S.T. is the first on-campus residence hall constructed by Rutgers since 1994.

| Aug 31, 2011

Wythe Confectionary renovation in Brooklyn completed

Renovation retains architectural heritage while reflecting a modern urban lifestyle.

| Feb 22, 2011

New EcoSpec Tile company offers recycled tiles

EcoSpec Tile LLC, established February 1, 2011, is a new tile manufacturing company started by a group consisting of experienced/time-tested tile professionals who collectively feel a strong responsibility to their industry and to their planet. The initial product offering includes sustainable tile material composed of 50% pre-consumer waste, 20% post-consumer waste and 30% new material recycled contents.