This year, Philadelphia-based modular manufacturer and construction manager Volumetric Building Companies (VBC) is on track to produce somewhere between 800,000 and 1 million sf of modules for the residential and hospitality sectors.

The company has been in growth mode for nearly two years, during which it acquired the assets of the bankrupt modular tech firm Katerra that included a 577,000-sf manufacturing plant in Tracy, Calif.; and merged, in January 2022, with the Poland-based modular manufacturer Polcom, a marriage that added two steel module manufacturing facilities to VBC’s operations. VBC recently moved another plant from North Carolina to Pennsylvania. All told, the company operates within more than 1.25 million sf of manufacturing space.

VBC’s founder Vaughan Buckley told the Australian website builtoffsite.com last year that the goal for his company is to hit $1 billion in annual revenue by 2025. To that end, VBC last year set up a $100 million development fund. VBC's six-person board of directors includes Adam Hieber, Executive Vice President with the global investment firm PIMCO; and Fred Tuomi, the retired CEO and Trustee of Invitation Homes, the largest single-family rental REIT in the U.S.

Housing shortage opens door for more modular construction

In an interview with BD+C last week, Sara-Ann Logan, AIA, RIBA, NOMA, IIDA, VBC’s Vice President of Design, said that her company’s four factories were booked out for the next six to 12 months, depending on the location. This year, about half of VBC’s modular production will go toward the construction of affordable multifamily housing, with another 15 to 20 percent for market-rate multifamily housing, and the rest for hotels.

VBC has revved up its production capacity at a time when the U.S. housing market saw the gap between household formation and new-home construction widen to 6.5 million units over the past decade, according to the latest Realtor.com estimates.

Logan concedes that the localized nature of the American housing market mitigates against devising national solutions for this chronic housing shortage. So-called industrialized housing that is made off-site in factories and assembled onsite, still only accounts for a single-digit sliver of total annual single- and multifamily-housing construction.

But Logan is also heartened that community resistance to multifamily housing in general, and modular housing in particular, has waned as developers and producers have demonstrated that modular homes can be built faster and are amenable to a variety of designs, styles and materials.

VBC started as a construction company 12 years ago and has since evolved into what Logan calls “a one-stop shop” that can design, manufacture, and assemble large-scale modular buildings. As of March 2023, it had completed over 30 housing and hospitality projects in Philadelphia, London, Seattle, Canada, and the Netherlands. VBC claims that its projects are completed two times faster than traditional construction, and with considerably greater budgeting certainty.

“We focus on the efficiencies of each piece, and are trying to break the modular box,” she said.

Latest modular project would have all-electric infrastructure

One of the latest projects that VBC has self-developed is a 149-unit housing building located at 1314 Spring Garden Street in Philadelphia. Logan said this project, with five above-ground floors and a roof deck proposed, would be one of the more advanced that her company has tackled thus far, with “lots of balconies,” and carveouts in the façade.

According to the Civic Design Review application that VBC filed with the city’s Department of Planning and Development on March 13, the building, sitting on 0.47 acres, will include 96 studios sized at 432 sf, 48 junior one-bedroom apartments at 496 sf each, and five two-bedroom apartments that will be 992 sf. The building will include 1,598 sf of ground-floor retail or restaurant space, a below-ground fitness center, 28 underground parking spaces, 60 covered and secured bike racks, and a green and blue roof system to assist the city’s stormwater management.

Other sustainable features include an all-electric infrastructure, and a 50 percent reduction of construction waste. The apartments will be furnished and include “automated furniture” that, Logan explained, are motorized beds and closets for flexibility. “The key to affordability,” she said, “is learning to live in less space.”

VBC is tentatively scheduled to begin production of the modules for 1314 Spring Garden Street in late April or early May, and is targeting the summer of 2024 for the project’s completion.

Related Stories

Sponsored | | Nov 26, 2014

A conversation with Paul Raiford, Director of Energy Services

Q&A with Paul Raiford, Director of Energy Services with Williams Scotsman. SPONSORED CONTENT

| Nov 24, 2014

Must see: Plans released for underwater city that could house 5,000 people

The design centers around a floating, 500-meter-wide sphere linked to a resource center on the ocean floor via a 15-kilometer, helix-shaped path.

Sponsored | | Nov 19, 2014

Build green while you work green

Leading general contractors, including Skanska USA and Turner Construction, are implementing sustainable modular jobsite offices throughout the country. SPONSORED CONTENT

| Nov 18, 2014

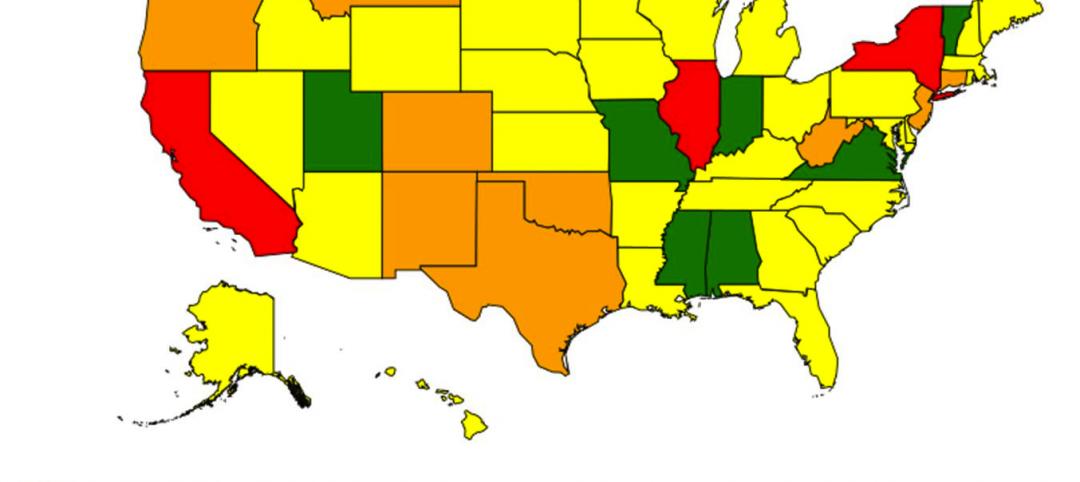

New tool helps developers, contractors identify geographic risk for construction

The new interactive tool from Aon Risk Solutions provides real-time updates pertaining to the risk climate of municipalities across the U.S.

Sponsored | | Nov 12, 2014

Williams Scotsman plugs into the jobsite

Many of our customers conduct important business from their temporary modular jobsite office and most require access to technology to get their job done effectively and efficiently. SPONSORED CONTENT

| Oct 29, 2014

Better guidance for appraising green buildings is steadily emerging

The Appraisal Foundation is striving to improve appraisers’ understanding of green valuation.

Sponsored | | Oct 29, 2014

Historic Washington elementary school incorporates modular design

More and more architects and designers are leveraging modern modular building techniques for expansion projects planned on historical sites. SPONSORED CONTENT

Sponsored | | Oct 24, 2014

Infographic: 5 key considerations for securing modular workspace

Keep these five considerations in mind for your next project that may benefit from modular space. SPONSORED CONTENT

| Oct 21, 2014

Check out BD+C's GreenZone Environment Education Classroom debuting this week at Greenbuild

At the conclusion of the show, the modular classroom structure will be moved to a permanent location in New Orleans' Lower 9th Ward, where it will serve as a community center and K-12 classroom.

Sponsored | | Oct 16, 2014

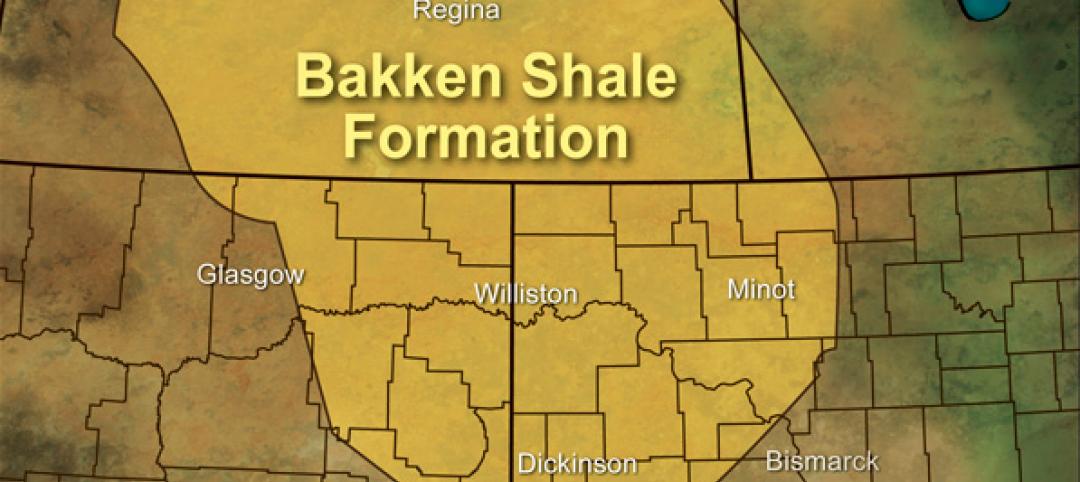

Drilling deeper: The booming Bakken Shale region

The Bakken Shale region, which spans from central North Dakota to the northeastern corner of Montana, is rapidly growing as a result of the oil and gas boom. SPONSORED CONTENT