Euclid Chemical, based in Cleveland, has been supplying the construction industry with products to improve the strength, appearance, and usability of concrete since 1910. Now a large, multi-national corporation, Euclid Chemical’s main offices are in a two-story, 15,000 square foot building that also contains laboratories where they develop products ranging from sealants to micro synthetic fibers.

Until recently, the building relied upon an aging VAV system with terminal reheat to keep their offices comfortable and to maintain environmental conditions in the laboratories. Even when new, records showed the system had not performed as designed. This inadequate performance was compounded by cumulative effects of years of normal wear and tear along with questionable modifications.

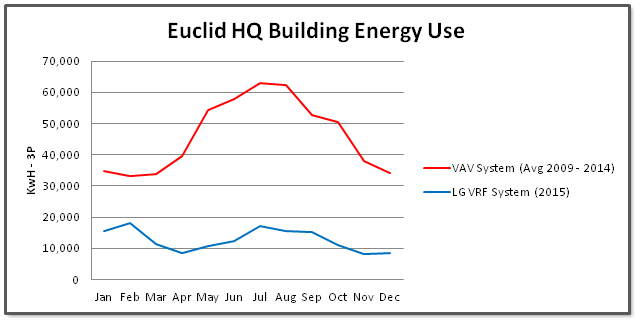

Ultimately, the system no longer kept people comfortable, broke down frequently and was incredibly inefficient. After analyzing the utility bills, Joe Messer, Director of Engineering for Euclid Chemical, realized that building had an average annual energy use of 38 kWh/square foot -- over twice the average consumption for offices in the same geographic area, and more than most of Euclid’s manufacturing facilities. Messer knew Euclid Chemical needed to upgrade to a dependable and efficient system that would meet their needs for years to come.

CRITERIA:

The building housed both office areas and laboratories, so throughout the facility the system had to provide individual temperature control which, at any given time, may require both heating and cooling in different areas.

In the lab, the system also had to account for the unique challenge of quickly adapting to rapidly changing make-up air requirements as laboratory fume hoods started and stopped. It also had to work in the Ohio climate where the outdoor temperature ranged from sub-zero weather in the winter to humid high-90’s in the summer. But above all else, the system had to have a manageable upfront cost and an attractive payback to the Euclid financial team.

SOLUTION:

Messer began the process of finding a new solution and reached out to trusted engineer Andy Culberson of Geisel Heating and Cooling. Culberson identified VRF (Variable Refrigerant Flow) technology as the optimum solution, and reached out to Peter Eno of Refrigeration Sales Corporation to collaborate on a best-in-class solution based on VRF technology from LG Electronics. Together they designed a system around LG Multi-V heat recovery systems.

The bulky 50 ton DX unit on the roof was replaced by a pair of small air-cooled outdoor units on the ground, and the VAV boxes inside the building were replaced with LG’s concealed high-static VRF indoor units. To account for the need for ventilation air and makeup air when the laboratory fume hoods were in use, a small makeup air unit with a water heating coil was added to provide ventilation air at a high-static pressure to the LG VRF indoor units. Since this was 100 percent outdoor air, the airflow could be adjusted to precisely meet the ventilation requirements as they changed. The LG Multi V is a heat recovery system, so it can heat the zones that need it while cooling others simultaneously which delivers precise temperature in all parts of the facility regardless of Ohio’s weather, including subzero winters.

After they presented the system proposal, everyone at Euclid Chemical was sold on the concept. Based on the problems and poor performance of the existing system, Messer conservatively estimated the new system would cut their utility bills by 40 percent. What’s more, they could reuse the existing distribution and supply ductwork, reducing upfront installation costs, which further sold the financial team.

RESULTS:

Once construction was completed, the system performance exceeded expectations, according to Messer. After implementation, the facility saw a 70 percent annual energy reduction compared to the average of the previous five years. (See graph.)

Equally important, the new system provides a quiet, comfortable environment for people to work. “Employees have definitely noticed an improvement in comfort,” said Messer. “This allowed us to focus on our core business instead of worrying about HVAC.” He is currently evaluating other buildings within the Euclid portfolio and, not surprisingly, he’s considering LG VRF solutions.

Related Stories

Affordable Housing | Feb 22, 2023

Passive House, sustainability standards meet multifamily development

These multifamily developments are not only Passive House (PHIUS) certified, but affordable for tenants.

Senior Living Design | Feb 15, 2023

Passive House affordable senior housing project opens in Boston

Work on Phase Three C of The Anne M. Lynch Homes at Old Colony, a 55-apartment midrise building in Boston that stands out for its use of Passive House design principles, was recently completed. Designed by The Architectural Team (TAT), the four-story structure was informed throughout by Passive House principles and standards.

Sustainability | Feb 9, 2023

University of Southern California's sustainability guidelines emphasize embodied carbon

A Buro Happold-led team recently completed work on the USC Sustainable Design & Construction Guidelines for the University of Southern California. The document sets out sustainable strategies for the design and construction of new buildings, renovations, and asset renewal projects.

Sustainability | Feb 8, 2023

A wind energy system—without the blades—can be placed on commercial building rooftops

Aeromine Technologies’ bladeless system captures and amplifies a building’s airflow like airfoils on a race car.

Green | Jan 26, 2023

Corporations fall short on climate pledges by failing to embed net-zero actions into operations

Many corporations are failing to implement simple, practical steps needed for them to hit their stated decarbonization goals, according to a survey of more than 300 operations managers across key industrial sectors including construction, energy, and chemicals in the U.S., U.K., and Germany.

Green | Jan 17, 2023

Top 10 U.S. states for green building in 2022

The U.S. Green Building Council (USGBC) released its annual ranking of U.S. states leading the way on green building, with Massachusetts topping the list. The USGBC ranking is based on LEED-certified gross square footage per capita over the past year.

Cladding and Facade Systems | Dec 20, 2022

Acoustic design considerations at the building envelope

Acentech's Ben Markham identifies the primary concerns with acoustic performance at the building envelope and offers proven solutions for mitigating acoustic issues.

Green | Dec 9, 2022

Reaching carbon neutrality in building portfolios ranks high for organizations

Reaching carbon neutrality with their building portfolios ranks high in importance among sustainability goals for organizations responding to a Honeywell/Reuters survey of senior executives at 187 large, multinational corporations. Nearly nine in 10 respondents (87%) say that achieving carbon neutrality in their building portfolio is either extremely (58%) or somewhat (29%) important in relation to their overall ESG goals. Only 4% of respondents called it unimportant.

Green | Dec 9, 2022

Newly formed Net Zero Built Environment Council aims to decarbonize the built world

Global management consulting firm McKinsey recently launched the Net Zero Built Environment Council, a cross-sector coalition of industry stakeholders aiming to decarbonize the built world. The council’s chief goal is to collaboratively create new pathways to cut greenhouse gas emissions from buildings.

Office Buildings | Dec 6, 2022

‘Chicago’s healthiest office tower’ achieves LEED Gold, WELL Platinum, and WiredScore Platinum

Goettsch Partners (GP) recently completed 320 South Canal, billed as “Chicago’s healthiest office tower,” according to the architecture firm. Located across the street from Chicago Union Station and close to major expressways, the 51-story tower totals 1,740,000 sf. It includes a conference center, fitness center, restaurant, to-go market, branch bank, and a cocktail lounge in an adjacent structure, as well as parking for 324 cars/electric vehicles and 114 bicycles.