London-based design firm Bryden Wood, with offices in Singapore, Barcelona, and Milan, will bolster its presence in the United States when it opens new headquarters in Boston this summer.

Founded in 1995, the firm now specializes in a value-oriented kit-of-parts “Platform” approach to design for manufacturing and assembly (DfMA). Bryden Wood’s North American expansion is being led by directors Jaimie Johnstone and Phil Langley, its head of global systems and creative technologies, respectively.

In an interview with BD+C last week, Johnston said that Bryden Wood’s plans to expand into the U.S. in 2020 were postponed because of the coronavirus pandemic. Prior to its moving into Boston, Bryden Wood had done some work in the U.S. for the pharmaceutical firm GlaxoSmithKline. Among the AEC and service-provider firms currently teaming with Bryden Wood on industrial projects in the U.S. are The Boldt Company, Amazon Web Services, and DPR Construction.

The timing of its expansion, said Johnston, was motivated by the slow-moving pace in the U.K. toward adopting offsite manufacturing as an element of commercial construction. “There have been pockets of excellence, but also more of a focus on volumetric modular for homebuilding.” The opposite is occurring in the U.S., he observed, where nonresidential developers and their AEC have been embracing prefabrication. Bryden Wood’s goal is to establish a North American supply network for industrial components.

Johnston noted that while “a lot of people” in the U.S. are prefabricating MEP components, that competitive advantage “can be diluted over time.” What Bryden Wood offers, he explained, is a merging of volumetric design with manufacturing for better and quicker results.

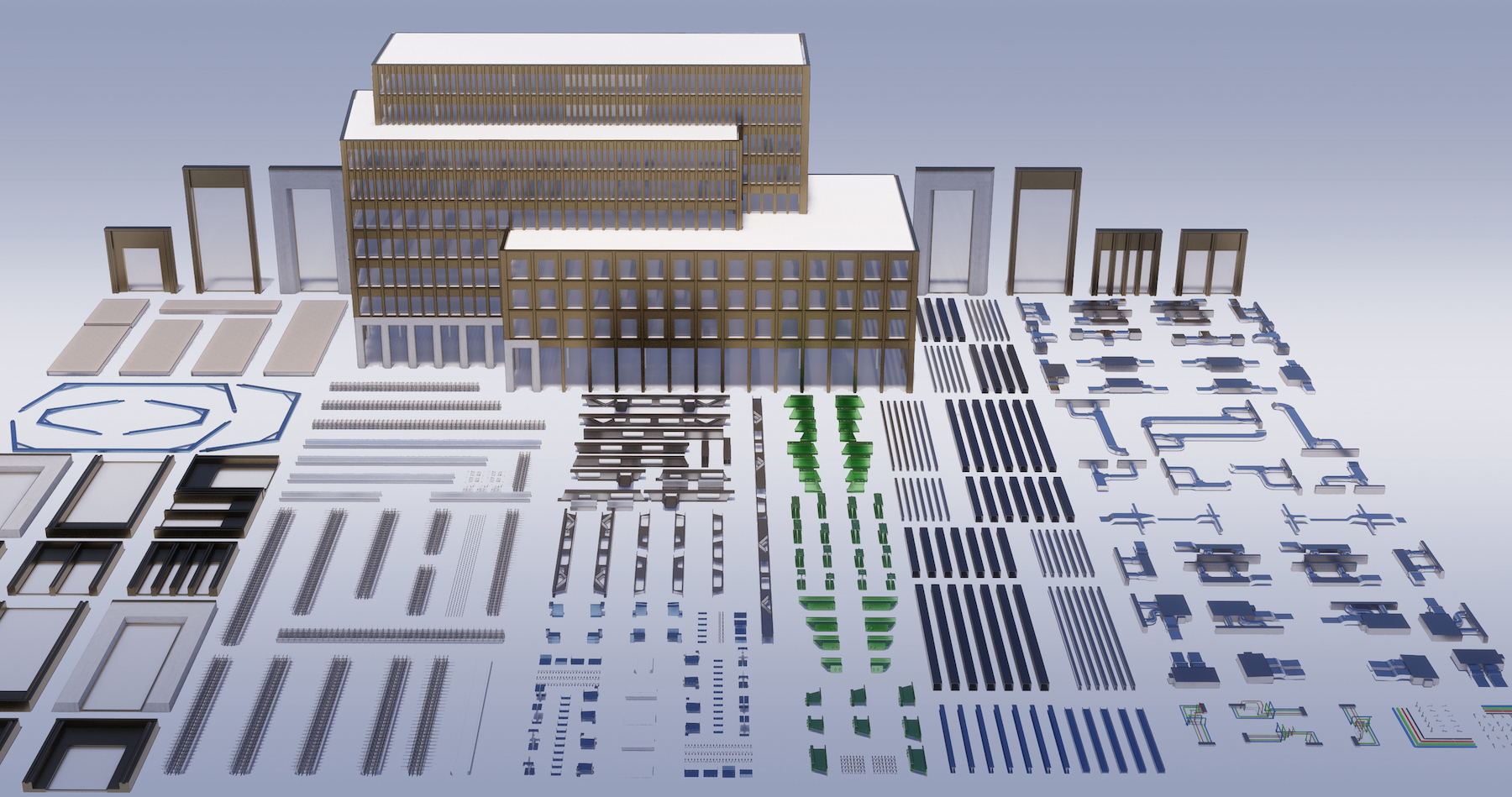

Bryden Wood’s Platform approach standardizes manufactured components that are made offsite and assembled onsite, thereby assuring greater certainty about schedules and budgets. Platforms also embed materials reuse and reductions in carbon into early stages of design.

The firm works with tech clients to develop design technologies such as “digital configurators” that rely on genetic algorithms to generate thousands of design and engineering solutions for sites around the world. By developing solutions that allow appropriate levels of repeatability in such building types as data centers, without sacrificing quality, “we’re helping [clients] transform their businesses,” said Johnston in a prepared statement.

THE FORGE SHOWCASES PLATFORM-DRIVEN SAVINGS

The Forge has been much quicker and more accurate.

The first major commercial project being delivered using the Platform approach to DfMA is The Forge, which topped out last December, and is scheduled for completion in the fourth quarter of this year. The Forge is comprised of two sustainably focused nine-story commercial buildings—90,000 and 49,000 sf, respectively—in central London, built around an accessible courtyard. Its projected efficiencies include a nearly 20 percent reduction in embodied carbon per square meter, a 36.4 percent reduction in the substructure, and a 20.2 reduction in superstructure and façade materials. Johnston said that the buildings’ façade panels could be installed in just 7½ minutes each, and with greater accuracy.

The Forge’s developer, Landsea, anticipates a 9.5 percent reduction in capital costs from this platform kit-of-parts approach. The Forge is also the U.K’s first net-zero energy project. The building team includes a joint venture between the construction firms Sir Robert McAlpine and Mace, and NG Bailey as the MEP engineer.

Johnston expected Bryden Wood to focus its attention in North American on projects for healthcare, data centers, pharma, and industrial, “wherever there’s a high degree of complexity and repetition.” On its website, Bryden Wood said it has been designing data centers since 1999, and has been delivering 30-40 percent reductions in capital build costs per kilowatt, and an average 40 percent increase in IT yield per square meter.

Scalability via industrialized construction for these building types is where clients are most likely to benefit from improvements in design and delivery, the firm contended. Johnston also foresaw Bryden Wood doing a bit more multifamily design in the U.S. than it does within its home market.

A few years ago, the firm launched a free-to-use and open-source housing design application called PRiSM that, it claims, brings together central and regional government, investors, developers, and manufacturers, with the goal of driving improved productivity and quality. The updated version of PRiSM incorporates Bryden Wood’s Platforms approach to DfMA.

Related Stories

| Aug 11, 2010

Goettsch Partners wins design competition for Soochow Securities HQ in China

Goettsch Partners (GP) has been selected as the winning firm in the competition to design the Soochow Securities Headquarters, the new office and stock exchange building for Soochow Securities Co. Ltd. The 21-story, 441,300-square-foot project includes 344,400 square feet of office space, an 86,100-square-foot stock exchange, meeting rooms, classrooms, a cafeteria, and underground parking for 400 cars and 800 bicycles.

| Aug 11, 2010

RMJM unveils design details for $1B green development in Turkey

International architecture company RMJM today announced details of the $1 billion Varyap Meridian development it is designing in Istanbul’s new residential and business district, which will be one of the "greenest" projects in Turkey. The luxury 372,000-square-meter development on a site totalling 107,000 square meters will be located in the Atasehir district of Istanbul, which the Turkish government intends to transform into the country’s new financial district and business center.

| Aug 11, 2010

Urban Land Institute honors five 'outstanding' developments in Europe, Middle East, and Africa

Five outstanding developments have been selected as winners of the Urban Land Institute (ULI) 2009 Awards for Excellence: Europe, Middle East, and Africa (EMEA) competition. This year, the competition also included the announcement of two special award winners. The Awards for Excellence competition is widely regarded as the land use industry’s most prestigious recognition program.

| Aug 11, 2010

Design firms slash IT spending in 2009

Over half of architecture, engineering, and environmental consulting firms (55%) are budgeting less for information technology in 2009 than they did in 2008, according to a new report from ZweigWhite. The 2009 Information Technology Survey reports that firms' 2009 IT budgets are a median of 3.3% of net service revenue, down from 3.6% in 2008. Firms planning to decrease spending are expected to do so by a median of 20%.

| Aug 11, 2010

A glimmer of hope amid grim news as construction employment falls in most states, metro areas

The construction employment picture brightened slightly with 18 states adding construction jobs from April to May according to a new analysis of data released today by the Bureau of Labor Statistics (BLS). However, construction employment overall continued to decline, noted Ken Simonson, the chief economist for the Associated General Contractors of America.

| Aug 11, 2010

Thom Mayne unveils 'floating cube' design for the Perot Museum of Nature and Science in Dallas

Calling it a “living educational tool featuring architecture inspired by nature and science,” Pritzker Prize Laureate Thom Mayne and leaders from the Museum of Nature & Science unveiled the schematic designs and building model for the Perot Museum of Nature & Science at Victory Park. Groundbreaking on the approximately $185 million project will be held later this fall, and the Museum is expected to open by early 2013.

| Aug 11, 2010

SOM's William F. Baker awarded Fritz Leonhardt Prize for achievement in structural engineering

In recognition of his engineering accomplishments, which include many of the tallest skyscrapers of our time, William F. Baker received the coveted Fritz Leonhardt Prize in Stuttgart, Germany. He is the first American to receive the prize.

| Aug 11, 2010

American Concrete Institute forms technical committee on BIM for concrete structures

The American Concrete Institute (ACI) announces the formation of a new technical committee on Building Information Modeling (BIM) of Concrete Structures.