This fall, the world’s tallest modular hotel—a 26-story, 360-foot-tall building that will be branded AC Hotel New York NoMad when it opens late next year—will start stacking prefabricated and prefurnished guestrooms for assembly in New York City.

This is one of 50 projects that Marriott International, since launching its pilot modular initiative in 2015, has incorporated prefab guestrooms or bathrooms.

In May, the hotelier developed specific modular concepts for its Fairfield Inn, Courtyard, SpringHill Suites, TownePlace, and Four Points by Sheraton brands. It deploys modular construction for its AC Hotels brand, and later this year will start stacking its first modular-built Moxy hotel in the U.S., in Oakland, Calif.

Jennifer Abuzeid, Senior Director–Global Design Strategies, says that Marriott began exploring modular construction in response to its post-recession pipeline expanding. (That pipeline currently exceeds 4,000 hotels for all of its brands.) Couple that with a dicey labor market, which put a major crimp in scheduling: a 120- to 150-room Courtyard hotel was taking 21 months to complete, compared to 12 months prerecession, says Abuzeid.

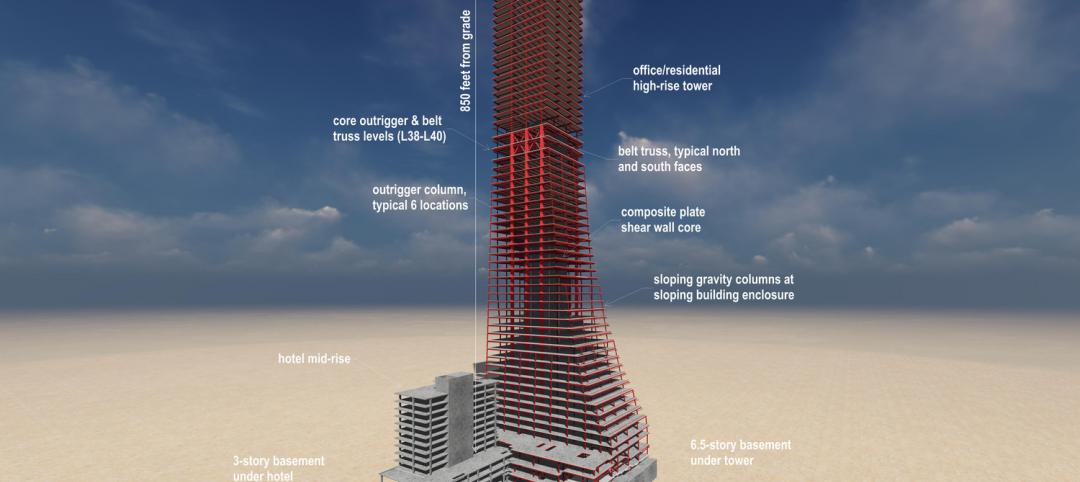

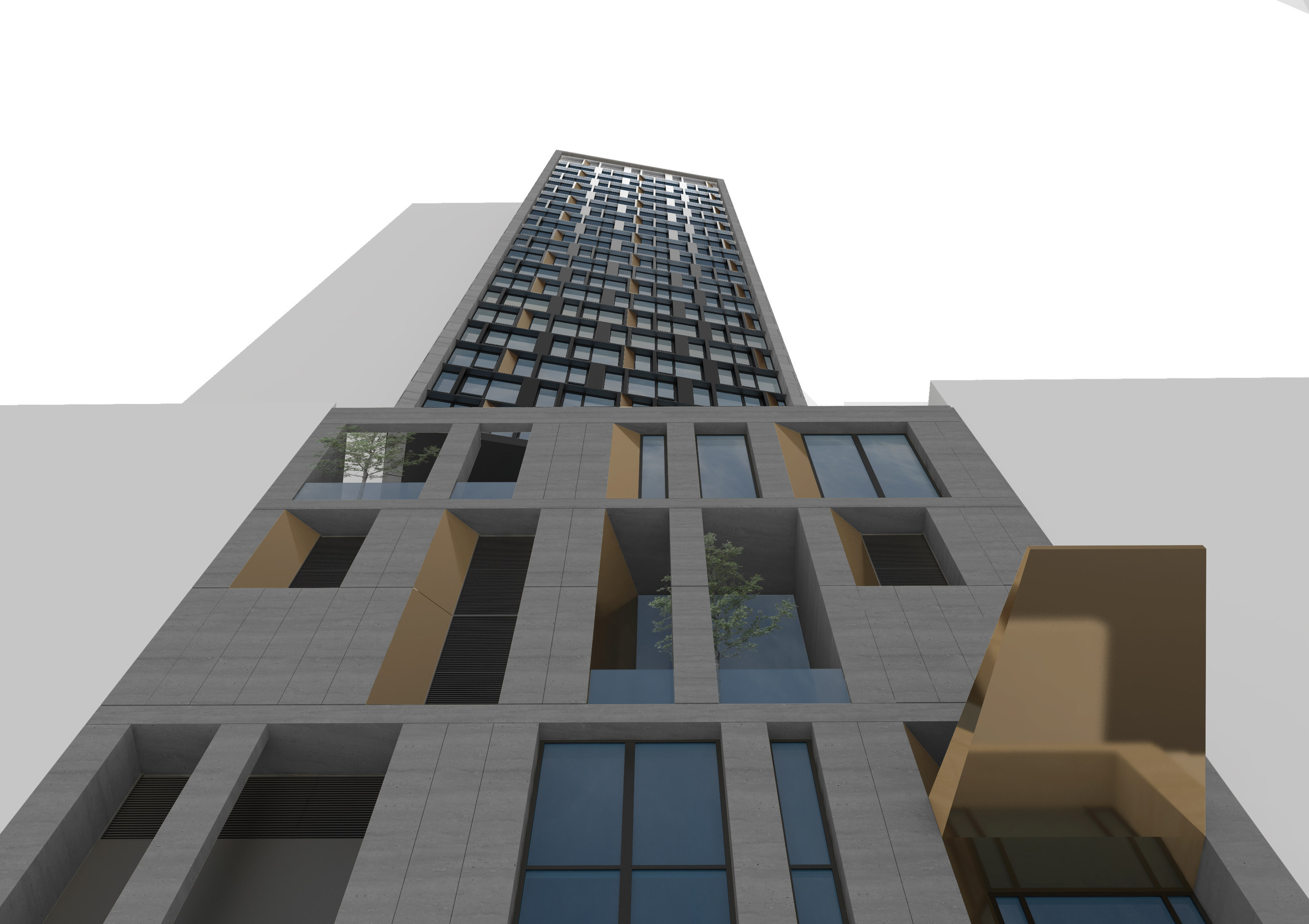

At 26 stories and 360 feet, Marriott International's AC Hotel New York NoMad will be the world’s tallest modular hotel when it opens next year. Besides finished, painted walls, each module will contain a fully outfitted guest room, with beds, sheets, pillows, flooring, even toiletries, according to architect Danny Forster & Architecture. Associate architect: Epstein. Photo courtesy Marriott Intl. and Danny Forster & Architecture

At 26 stories and 360 feet, Marriott International's AC Hotel New York NoMad will be the world’s tallest modular hotel when it opens next year. Besides finished, painted walls, each module will contain a fully outfitted guest room, with beds, sheets, pillows, flooring, even toiletries, according to architect Danny Forster & Architecture. Associate architect: Epstein. Photo courtesy Marriott Intl. and Danny Forster & Architecture

Abuzeid admits that Marriott’s embrace of modular construction has been a learning curve. Finding enough module manufacturers to meet its needs continues to be a battle. Skystone Group is the General Contractor and Modular Manufacturer on this New York AC Hotel project. It manufactures the modules using a Europe-based supply chain: DMD Modular, STP Elbud, and Aluprof are the main subcontractors contributing to the modular scope, according to Greg Thompson, Chief Financial Officer for Skystone Group.*

But the “great benefits” of modular, she says, include consistent product quality, eliminating change orders, and reducing punch lists and jobsite waste.

Marriott has an in-house design team that sets the prototype parameters for its brands. Its franchisees hire the building teams and module suppliers to construct the hotels. This year, Marriott began offering incentives to developers that leverage prefabrication for guestroom construction.

SEE ALSO: Mace Group built working factories on top of under-construction skyscrapers

Abuzeid estimates that modular production and assembly shave anywhere from three to eight months off of a hotel’s construction time. She adds that the franchisee that built the 354-key, dual-branded Courtyard and TownePlace Suites by Marriott property in Hawthorne, Calif., may have reduced its construction period by a year “in a very difficult real estate market.”

Abuzeid estimates that 40% of Marriott’s Select brands in North America, which account for more than two-fifths of its backlog, has the potential for modular construction.

“We consider modular design and construction very important to our expansion strategy in North America, where it’s currently not as commonly leveraged as in other parts of the world,” says Eric Jacobs, Marriott International’s Chief Development Officer for Marriott Select Service and Extended Stay Brands in North America.

*Information about Skystone Group's role Marriott's AC Hotel project was added after this story was originally posted.

Marriott's Jennifer Abuzeid, Senior Director–Global Design Strategies, estimates that modular production and assembly shave anywhere from three to eight months off of a hotel’s construction time. She adds that the franchisee that built the 354-key, dual-branded Courtyard and TownePlace Suites by Marriott property in Hawthorne, Calif., may have reduced its construction period by a year “in a very difficult real estate market.” Photo: Marriott

Marriott's Jennifer Abuzeid, Senior Director–Global Design Strategies, estimates that modular production and assembly shave anywhere from three to eight months off of a hotel’s construction time. She adds that the franchisee that built the 354-key, dual-branded Courtyard and TownePlace Suites by Marriott property in Hawthorne, Calif., may have reduced its construction period by a year “in a very difficult real estate market.” Photo: Marriott

Related Stories

AEC Innovators | Mar 5, 2020

These 17 women are changing the face of construction

During this Women in Construction Week, we shine a spotlight on 17 female leaders in design, construction, and real estate to spur an important conversation of diversity, inclusion, and empowerment.

AEC Innovators | Aug 27, 2019

7 AEC industry disruptors and their groundbreaking achievements

From building prefab factories in the sky to incubating the next generation of AEC tech startups, our 2019 class of AEC Innovators demonstrates that the industry is poised for a shakeup. Meet BD+C’s 2019 AEC Innovators.

AEC Innovators | Aug 27, 2019

How engineering giant BuroHappold democratizes tech innovation

The firm's Computational Collective initiative presents employees with “a different way of thinking and working.”

AEC Innovators | Aug 26, 2019

Clayco seeks the cutting edge as a competitive advantage

Innovation has been in Clayco’s DNA since this general contractor was founded in 1984.

AEC Innovators | Aug 15, 2019

Oracle’s replica of a construction jobsite creates an immersive environment for AEC professionals

The Oracle Construction and Engineering Innovation Lab allows visitors to walk through five different stages of construction work, to test new AEC technologies and training techniques.

AEC Innovators | Aug 9, 2019

Improving architectural designs through iteration

Computational design lets ZGF Architects see patterns that renderings and even models can’t show.

AEC Innovators | Aug 6, 2019

Structural engineer speeds skyscraper construction with novel building core design

With its Speed Core composite core wall system, Magnusson Klemencic Associates thinks it’s found a faster way to complete high-rise buildings.

AEC Innovators | Aug 5, 2019

Mace Group builds working on top of under-construction skyscrapers

The six-story factories eliminated the need for tower cranes, and increased productivity to the point where crews could complete 18 floors in 18 weeks.