A 19-story building under construction in San Jose, Calif., will be the second in the country to be built with a concrete-filled composite plate shear wall system, which was first used successfully two years ago for construction of the 58-story Rainer Square tower in Seattle.

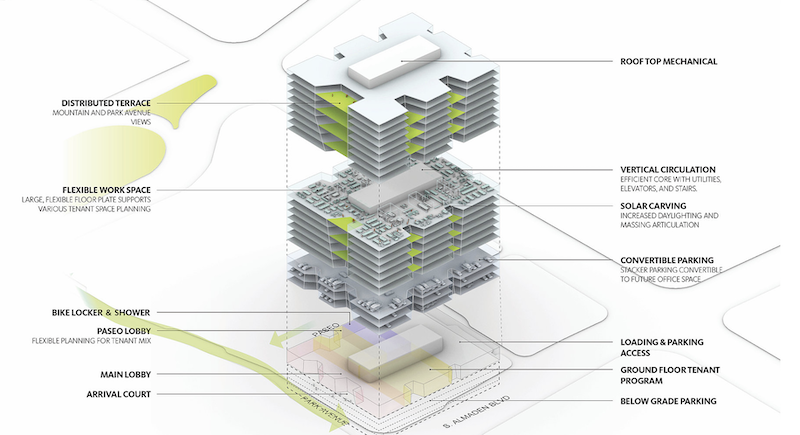

Level 10 Construction is the general contractor on the San Jose project, known locally as 200 Park, a Class A office building that, when it’s completed in May 2023, will have 937,000 sf that include 26,000 sf of outdoor terraces. The building’s owner, Jay Paul Company, is targeting LEED Gold certification. When it’s completed, 200 Park will be San Jose’s tallest office tower.

200 Park Conceptual Structural Steel Sequence from Level 10 Construction on Vimeo.

The wall system, known as Speed Core, is expected to reduce the construction time for 200 Park by three months, according to Kevin Englund, Level 10’s Partner and Vice President. Level 10 started construction on this project in March, and the Speed Core portion should be completed next year.

The building team on this project includes Gensler (architect), and Magnusson Klemencic Associates (SE and CE), which has been Speed Core’s biggest advocate. MKA was part of the project team that completed Rainer Square tower’s core nine months ahead of schedule.

200 Park in San Jose, Calif., will have 937,000 of rentable square footage, and 26,000 sf of outdoor terraces (below). Images: Jay Paul Company

FASTER AND SAFER CONSTRUCTION

The SpeedCore system relies on two steel plates connected with steel cross ties, which are then filled with high-strength concrete. (For the San Jose project, the steel section is filled with 10,000-psi grout for the structural core.) The modular nature of these prefabricated “sandwich” panels allows for faster erection speed, since the system provides stability without requiring traditional rebar reinforcing or the temporary formwork of a typical concrete core, and progress is not dependent on concrete curing times.

Also see: 3D conceptual video of the structural steel sequence

Also see: The American Institute of Steel Construction’s profile of Speed Core

Off-site, Schuff Steel fabricated the panels for 200 Park, which weigh up to 12.5 tons, and then shipped the panels to the construction site.

As described in a 3D conceptual video of Speed Core’s steel structure sequence that Level 10 posted, stanchions are embedded in concrete shear walls and the floor slab is cast. Below-grade wall panels are erected and welded into place. Grade-level seismic struts are installed. Grade-level slab is cast and the erection proceeds. Speed Core wall panels carry up to eight floors of steel prior to concrete.

200 Park Avenue Mock-Up Installation from Level 10 Construction on Vimeo.

The average floorplate at 200 Park will be 54,000 sf. Image: Jay Paul Company

Related Stories

| Aug 11, 2010

Two Rivers Marketing: Industrial connection

It was supposed to be the perfect new office. In July 2003, Two Rivers Marketing Group of Des Moines, Iowa, began working with Shiffler Associates Architects on a 14,000-sf building to house their rapidly growing marketing firm. Over the next six months they put together an innovative program that drew on unprecedented amounts of employee feedback.

| Aug 11, 2010

AIA Course: Enclosure strategies for better buildings

Sustainability and energy efficiency depend not only on the overall design but also on the building's enclosure system. Whether it's via better air-infiltration control, thermal insulation, and moisture control, or more advanced strategies such as active façades with automated shading and venting or novel enclosure types such as double walls, Building Teams are delivering more efficient, better performing, and healthier building enclosures.

| Aug 11, 2010

Glass Wall Systems Open Up Closed Spaces

Sectioning off large open spaces without making everything feel closed off was the challenge faced by two very different projects—one an upscale food market in Napa Valley, the other a corporate office in Southern California. Movable glass wall systems proved to be the solution in both projects.

| Aug 11, 2010

Silver Award: Pere Marquette Depot Bay City, Mich.

For 38 years, the Pere Marquette Depot sat boarded up, broken down, and fire damaged. The Prairie-style building, with its distinctive orange iron-brick walls, was once the elegant Bay City, Mich., train station. The facility, which opened in 1904, served the Flint and Pere Marquette Railroad Company when the area was the epicenter of lumber processing for the shipbuilding and kit homebuilding ...

| Aug 11, 2010

Special Recognition: Durrant Group Headquarters, Dubuque, Iowa

Architecture firm Durrant Group used the redesign of its $3.7 million headquarters building as a way to showcase the firm's creativity, design talent, and technical expertise as well as to create a laboratory for experimentation and education. The Dubuque, Iowa, firm's stated desire was to set a high sustainability standard for both itself and its clients by recycling a 22,890-sf downtown buil...

| Aug 11, 2010

Thrown For a Loop in China

While the Bird's Nest and Water Cube captured all the TV coverage during the Beijing Olympics in August, the Rem Koolhaas-designed CCTV Headquarters in Beijing—known as the “Drunken Towers” or “Big Shorts,” for its unusual shape—is certain to steal the show when it opens next year.

| Aug 11, 2010

Top of the rock—Observation deck at Rockefeller Center

Opened in 1933, the observation deck at Rockefeller Center was designed to evoke the elegant promenades found on the period's luxury transatlantic liners—only with views of the city's skyline instead of the ocean. In 1986 this cultural landmark was closed to the public and sat unused for almost two decades.

| Aug 11, 2010

200 Fillmore

Built in 1963, the 32,000-sf 200 Fillmore building in Denver housed office and retail in a drab, outdated, and energy-splurging shell—a “style” made doubly disastrous by 200 Fillmore's function as the backdrop for a popular public plaza and outdoor café called “The Beach.

| Aug 11, 2010

Integrated Project Delivery builds a brave, new BIM world

Three-dimensional information, such as that provided by building information modeling, allows all members of the Building Team to visualize the many components of a project and how they work together. BIM and other 3D tools convey the idea and intent of the designer to the entire Building Team and lay the groundwork for integrated project delivery.

| Aug 11, 2010

Inspiring Offices: Office Design That Drives Creativity

Office design has always been linked to productivity—how many workers can be reasonably squeezed into a given space—but why isn’t it more frequently linked to creativity? “In general, I don’t think enough people link the design of space to business outcome,” says Janice Linster, partner with the Minneapolis design firm Studio Hive.