A recent survey of AEC firms and real estate owners and developers found a strong majority that had deployed off-site construction in the previous 12 months and planned to utilize it to a greater extent going forward.

The Off-Site Construction Council of the National Institute of Building Sciences in Washington, D.C. conducted its 2018 Off-Site Construction Industry Survey as a follow-up to a 2014 survey to gauge the industry’s interest in off-site construction, which it defines as the planning, design, fabrication, and assembly of building elements at a location other than their final point of assembly onsite.

Ryan Smith of Washington State University and Kambaja Tarr of the University of Utah conducted and compiled the latest survey for NIBS.

“With the ongoing shortage of skilled craft workers (which exceeded two million in 2017), prefabrication in a controlled, off-site environment may become a necessity for many U.S. contractors attempting to remain competitive with a lower-skilled workforce,” the survey states. But as with any new process or technology innovation, and despite growing demand, ”uncertainties accompany the utilization of off-site construction.”

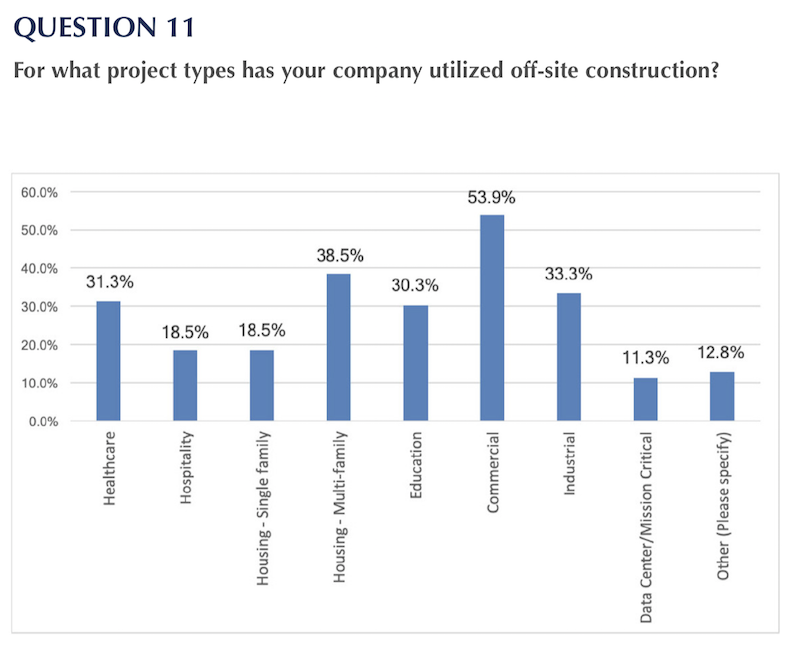

The commercial, multifamily and healthcare sectors are where off-site construction has been finding its greatest demand. Image: NIBS

A total of 205 participants responded to the 2018 Off-Site Construction Industry survey, versus 312 respondents to the 2014 poll. The participating companies provide a variety of different services, including construction management/general contracting (24.75% in 2018; 46.7% in 2014), engineering (21.72% and 38.3%), trade contracting (2.53% and 27.3%), architecture (87.88% and 15%), and owners/developers (10.1% and 8.3%).

Nearly nine of 10 respondents to the 2018 survey (87.72%) had used off-site fabricated components to some degree over the previous 12 months, and more than eight in 10 (81.63%) expected to engage off-site construction more often or the same amount in the following 12 months. (Both percentages were down slightly from the 2014 survey.)

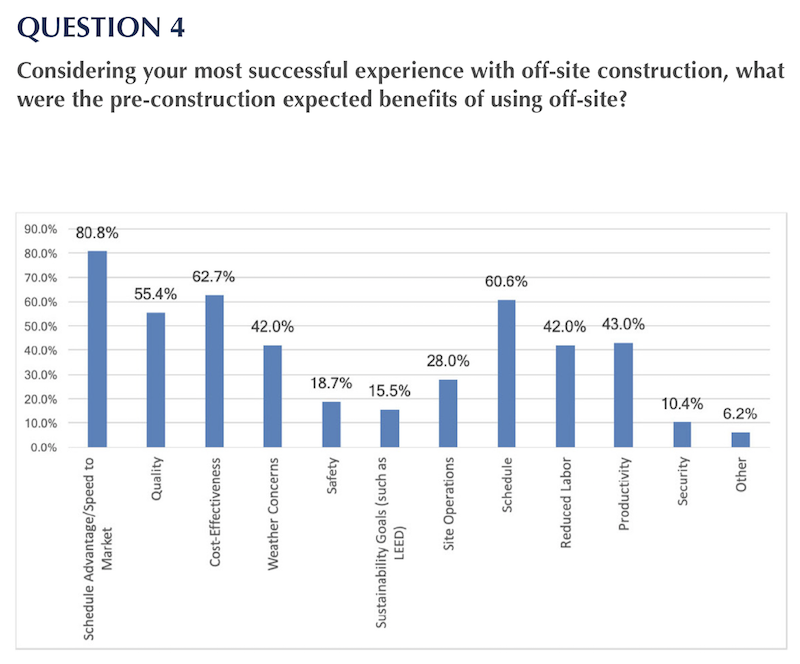

The primary benefit identified in both surveys is a reduced overall project schedule, specifically the duration of the construction phase.

For more than three fifths of respondents (63.22%) designers, architects and engineers were the primary decision makers about when off-site construction is implemented, followed by construction managers or general contractors (47.67%), clients (41.97%), and others, primarily subcontractors (21.24%).

Keeping projects on schedule is where companies that deploy off-site construction have been seeing the greatest benefit. Image: NIBS

Interestingly, however, respondents stated that the most significant barrier to off-site construction is the culture of design and construction in general. Comments indicated that late design changes, lack of collaboration and an adversarial climate for project delivery leads to difficulties in realizing the benefits of off-site construction.

The survey notes that the building component fabrication industry is still maturing and needs more time to integrate effectively with site-built work. In addition, contractors are still learning how to manage off-site products for assembly on-site.

Transportation is another significant barrier: specifically, how far away a factory is located from the construction site.

Respondents in both surveys qualitatively noted that some projects, particularly those with long spans, may not be suited for the use of pre-fabricated elements, and that each project has unique requirements that must be met through an appropriate technical solution.

Related Stories

| Aug 11, 2010

Will Alsop to head up new RMJM studio

Will Alsop, the internationally acclaimed British architect and designer of the Glenwood Waterfront project on the Hudson River, is to turn his attention once again to the U.S. after announcing he is to create a studio called “Will Alsop at RMJM,” as part of the RMJM worldwide architectural firm.

| Aug 11, 2010

AECOM, WATG top BD+C's ranking of the nation's 75 largest hotel design firms

A ranking of the Top 75 Hotel Design Firms based on Building Design+Construction's 2009 Giants 300 survey. For more Giants 300 rankings, visit http://www.BDCnetwork.com/Giants

| Aug 11, 2010

YKK AP launches enerGfacade family of building envelope products

YKK AP America, the leader in manufacturing high quality architectural products, today announced enerGfacade™, its new family of energy-efficient products, as part of the YKK Group’s 50 year anniversary in the architectural products business. The family includes several products, such as Luminance™, ThermaShadeTM and YOW350T.

| Aug 11, 2010

Parsons Brinckerhoff, Dewberry among nation's largest multifamily design firms, according to BD+C's Giants 300 report

A ranking of the Top 75 Multifamily Design Firms based on Building Design+Construction's 2009 Giants 300 survey. For more Giants 300 rankings, visit /giants

| Aug 11, 2010

USGBC’s Greenbuild 2009 brings global ideas to local main streets

Save the planet with indigenous knowledge. Make permanent water part of your life. Dive deep water for clues to environmental success. Connect site selection to successful creative concepting. Explore the unknown with Discovery Channel’s best known guide. These are but a few of the big ideas participants can connect to at USGBC’s Greenbuild International Conference and Expo, taking place on November 11-13, 2009 in Phoenix, Ariz.

| Aug 11, 2010

Goettsch Partners wins design competition for Soochow Securities HQ in China

Goettsch Partners (GP) has been selected as the winning firm in the competition to design the Soochow Securities Headquarters, the new office and stock exchange building for Soochow Securities Co. Ltd. The 21-story, 441,300-square-foot project includes 344,400 square feet of office space, an 86,100-square-foot stock exchange, meeting rooms, classrooms, a cafeteria, and underground parking for 400 cars and 800 bicycles.

| Aug 11, 2010

New York Mayor Bloomberg opens nation's first multi-story green industrial facility and announces new green manufacturing plant at Brooklyn Navy Yard

Mayor Michael R. Bloomberg, Deputy Mayor for Economic Development Robert C. Lieber, and Brooklyn Navy Yard Development Corporation Chairman Alan Fishman and President Andrew H. Kimball today opened the Perry Avenue Building, the nation's first multi-story green industrial facility at the Brooklyn Navy Yard. Mayor Bloomberg also announced the creation of Duggal Greenhouse, a 60,000-square-foot LEED Platinum certified facility.