A recent survey of AEC firms and real estate owners and developers found a strong majority that had deployed off-site construction in the previous 12 months and planned to utilize it to a greater extent going forward.

The Off-Site Construction Council of the National Institute of Building Sciences in Washington, D.C. conducted its 2018 Off-Site Construction Industry Survey as a follow-up to a 2014 survey to gauge the industry’s interest in off-site construction, which it defines as the planning, design, fabrication, and assembly of building elements at a location other than their final point of assembly onsite.

Ryan Smith of Washington State University and Kambaja Tarr of the University of Utah conducted and compiled the latest survey for NIBS.

“With the ongoing shortage of skilled craft workers (which exceeded two million in 2017), prefabrication in a controlled, off-site environment may become a necessity for many U.S. contractors attempting to remain competitive with a lower-skilled workforce,” the survey states. But as with any new process or technology innovation, and despite growing demand, ”uncertainties accompany the utilization of off-site construction.”

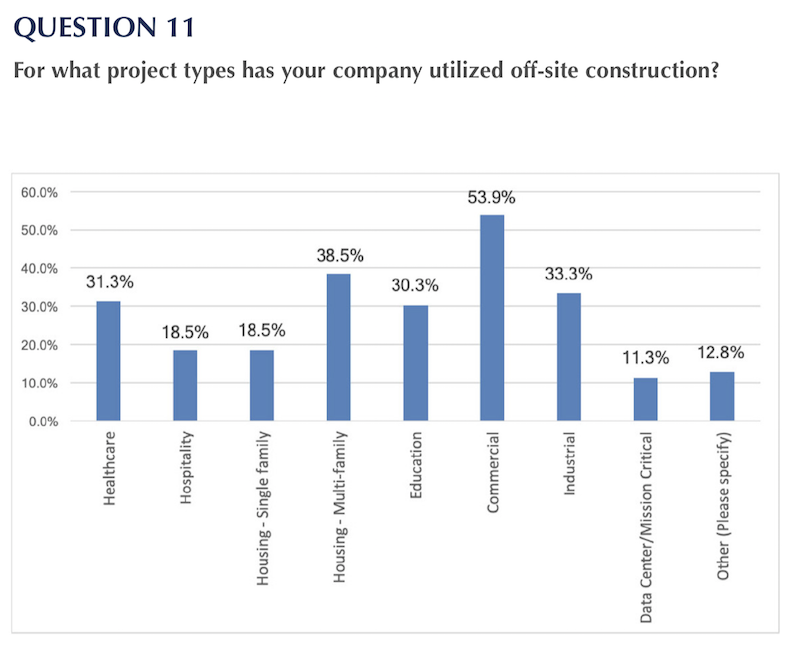

The commercial, multifamily and healthcare sectors are where off-site construction has been finding its greatest demand. Image: NIBS

A total of 205 participants responded to the 2018 Off-Site Construction Industry survey, versus 312 respondents to the 2014 poll. The participating companies provide a variety of different services, including construction management/general contracting (24.75% in 2018; 46.7% in 2014), engineering (21.72% and 38.3%), trade contracting (2.53% and 27.3%), architecture (87.88% and 15%), and owners/developers (10.1% and 8.3%).

Nearly nine of 10 respondents to the 2018 survey (87.72%) had used off-site fabricated components to some degree over the previous 12 months, and more than eight in 10 (81.63%) expected to engage off-site construction more often or the same amount in the following 12 months. (Both percentages were down slightly from the 2014 survey.)

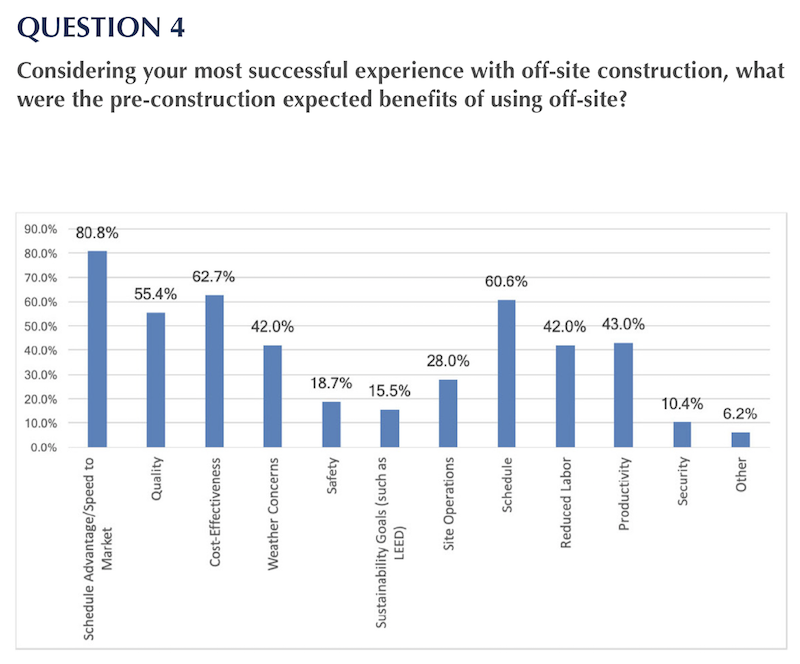

The primary benefit identified in both surveys is a reduced overall project schedule, specifically the duration of the construction phase.

For more than three fifths of respondents (63.22%) designers, architects and engineers were the primary decision makers about when off-site construction is implemented, followed by construction managers or general contractors (47.67%), clients (41.97%), and others, primarily subcontractors (21.24%).

Keeping projects on schedule is where companies that deploy off-site construction have been seeing the greatest benefit. Image: NIBS

Interestingly, however, respondents stated that the most significant barrier to off-site construction is the culture of design and construction in general. Comments indicated that late design changes, lack of collaboration and an adversarial climate for project delivery leads to difficulties in realizing the benefits of off-site construction.

The survey notes that the building component fabrication industry is still maturing and needs more time to integrate effectively with site-built work. In addition, contractors are still learning how to manage off-site products for assembly on-site.

Transportation is another significant barrier: specifically, how far away a factory is located from the construction site.

Respondents in both surveys qualitatively noted that some projects, particularly those with long spans, may not be suited for the use of pre-fabricated elements, and that each project has unique requirements that must be met through an appropriate technical solution.

Related Stories

Airports | Jul 8, 2022

Phoenix Sky Harbor Airport’s new terminal prioritizes passenger experience and sustainability

McCarthy Building Companies recently completed construction of the final concourse in Terminal 4 at Phoenix Sky Harbor International Airport.

Architects | Jul 7, 2022

Page acquires AE giant EYP to form 1,300-person international design firm

The combined firm will “be able to invest in research and thought leadership to co-create with our clients,” stated Page CEO Thomas McCarthy.

Building Team | Jul 7, 2022

Report explores improving architect/contractor relationship

A new study by the American Institute of Architects and the Associated General Contractors of America focuses on improving the relationship between architects and contractors.

Airports | Jul 7, 2022

Love at first flight: The power of first impressions in airports

As architects, how we design a terminal and choreograph the passenger experience can stir up strong feelings.

Building Team | Jul 7, 2022

Amenity-rich rental property in Chicago includes seven-story atrium with vertical landscaping

The recently opened 198-unit Optima Lakeview luxury rental apartment building in Chicago is bursting with amenities such as the region’s first year-round rooftop pool, contact-free in-home package delivery, housekeeping services, on-site room service, fitness programming, and a virtual personal assistant.

Multifamily Housing | Jul 6, 2022

The power of contextual housing development

Creating urban villages and vibrant communities starts with a better understanding of place, writes LPA's Matthew Porreca.

Building Team | Jul 6, 2022

Buro Happold selects Jennifer Price for top role, US Managing Director

Buro Happold, a world-class practice of 2,200 engineers and consultants, has announced the appointment of Seattle-based Jennifer Price as US Managing Director and Partner.

University Buildings | Jul 6, 2022

Wenzhou-Kean University opens a campus building that bridges China’s past and future

After pandemic-related stops and starts, Wenzhou-Kean University’s Ge Hekai Hall has finally begun to see full occupancy.

Security and Life Safety | Jul 5, 2022

What AEC firms should look for in a cybersecurity partner

When looking for expert partners in cybersecurity, AEC firms will find quite a lot of companies claiming to be at the forefront of modern threats. Here are five key points to look for when choosing a cybersecurity firm.

Performing Arts Centers | Jul 5, 2022

Tour the new Patricia Reser Center for the Arts in Oregon

This month, the community of Beaverton, Oregon, welcomed a new haven for artistic expression with the opening of Patricia Reser Center for the Arts (The Reser).