Trade labor shortages. Thinner margins. Tighter schedules. Quality control issues. Weather events. Increased complexity. Safety concerns. There is a laundry list of reasons why general contractors, construction managers, and subcontractors should be jumping in with both feet to adopt prefabrication on projects.

Many of the nation’s largest contractors, including Gilbane, Mortensen, Skanska, and Turner, have been utilizing prefab techniques on select projects for a decade or more. Mortensen, in a 2014 study, even quantified the cost and schedule savings from select prefab approaches—exterior panel walls, bathroom pods, multi-trade racks, patient room headwalls—implemented on a Denver hospital project. The company’s conclusion: For every dollar it spent on prefab, 13% of the investment was returned as a “quantifiable benefit to the project”—through schedule and cost certainty, improved productivity, fewer safety incidents, and manpower consistency. That’s a 1.13 benefit-to-cost ratio. Not too shabby.

Yet the prefab movement—while growing—has been relatively slow to take hold in a big way in the U.S. construction market, especially among GCs and CMs, according to a newly released joint study by FMI and BIM Forum.

Of the 156 firms surveyed for the report, nearly three-quarters (74%) indicated that they use some level of prefab on select projects. Solid adoption rate, right?

Now look at the numbers based on the volume of project work. Just 23% of respondents use prefab assemblies on more than half of their projects, and less than a third (32%) utilize the process on 21-50% of their firm’s projects.

Shockingly, among the firms that have adopted prefab construction, the overwhelming majority (86%) admit that the process is either “not effective” or “needs improvement.”

Even the most ardent users of prefab concede that the movement, for most firms, is still in the R&D phase. Construction teams don’t have the luxury of repetition. Each project comes with a different set of circumstances—location, client, project team, building program requirements, cost restraints, and schedule demands.

Trial and error testing requires multiple projects spanning several years to see what works and what doesn’t. Early prefab adopters like Birmingham, Ala.-based Golden Construction are just coming out of that cycle. “Ten years ago, we were just trying to prove that prefabrication worked,” the firm’s President Geoffrey Golden told FMI. “Today, the conversations have shifted to, ‘Just how much can we impact projects’ bottom line and schedule?’”

Mastering prefab, say the authors of the FMI/BIM Forum report, requires a top-down commitment to the process, a willingness to fail and try again, and an “all or nothing” mindset. Dabbling in prefab often turns into an expensive mistake.

Related Stories

| May 30, 2018

Accelerate Live! talk: An AEC giant’s roadmap for integrating design, manufacturing, and construction

In this 15-minute talk at BD+C’s Accelerate Live! conference (May 10, 2018, Chicago), Skender CEO Mark Skender and Chief Design Officer Tim Swanson present the construction giant’s vision for creating a manufacturing-minded, vertically-integrated design-manufacturing-build business model.

Augmented Reality | May 30, 2018

HoloLens used as wayfinding device to guide blind people through complex buildings

Neither training nor modification of the physical environment are required to use the system.

Architects | May 14, 2018

4 tactics for our digital transformation

While our technology is becoming more advanced, the fundamental processes at the core of design and construction businesses have largely remained unchanged for decades.

Virtual Reality | May 8, 2018

‘Bespoke’ VR apps give Woods Bagot an edge in presenting design ideas

The architectural firm is finding that some clients respond quicker to proposals as a result.

Architects | Apr 16, 2018

Is the AEC industry ready to shake off its retrograde image?

Technology has been and always will be perceived as a source for wonder and worry.

Building Technology | Apr 10, 2018

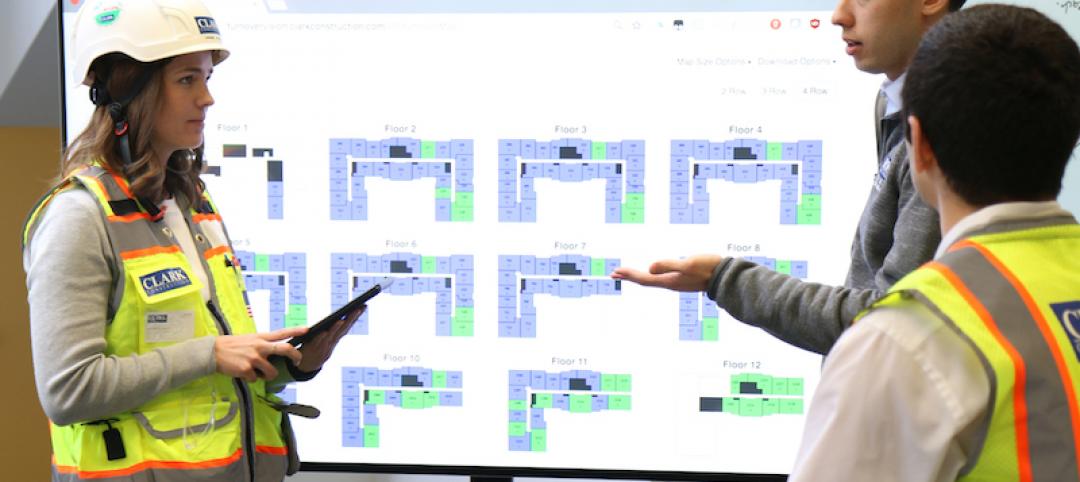

A jobsite dashboard is helping Clark Construction take the drudgery out of managing punch lists

Turnover Vision is the latest example of Clark digitizing its construction management process.

Contractors | Apr 9, 2018

Tech Report 5.0: Smart(er) Jobsites

Real-time construction analysis, just-in-time materials delivery, digital production planning systems—these are just a few of the novel approaches construction firms are implementing to take control of their jobsites.

Building Technology | Apr 9, 2018

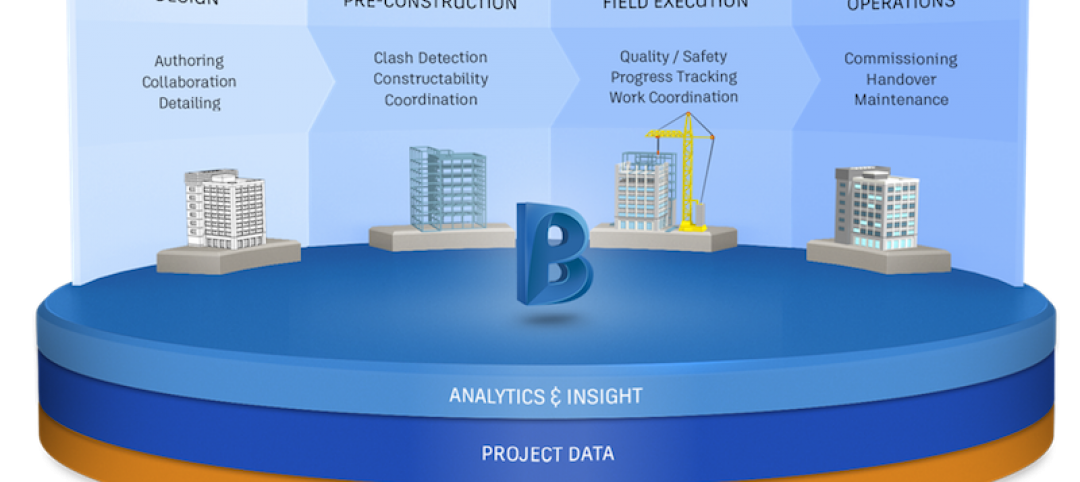

Autodesk opens its Forge platform, encouraging more suppliers to build onto it

The goal is to further streamline the construction process, from design to commissioning.

Architects | Apr 5, 2018

Tech Report 5.0: The Human Touch

Can studying humans at a behavioral level produce better buildings? Cognitive architecture experts are working to find out.

Building Technology | Apr 4, 2018

Tech Report 5.0: Digital Immersion

Indoor digital media changes the identities of buildings by stimulating occupant interaction.