In December 2019, a piece of terra cotta fell from a Manhattan tower, killing a passerby and prompting the New York City Department of Buildings to step up enforcement of the Façade Inspection and Safety Program (FISP). A new rule adopted on January 14, 2020 makes substantial changes to the inspection and reporting requirements for FISP, commonly known as Local Law 11. Here is a summary of the changes ahead.

New Standards for Qualified Exterior Wall Inspectors (QEWIs)

In past cycles, the QEWI responsible for façade inspection and report filing needed to be a registered design professional (architect or engineer) with at least one year of relevant experience. Now, a QEWI must have seven years of experience, specifically with façades over six stories. Those applying for QEWI status now must provide a detailed résumé and demonstrate familiarity with codes, laws, and rules pertaining to façades.

Prompting these changes were deficient façade inspection reports, which came to light when follow-up inspections revealed inaccuracies. Ramping up qualification requirements for QEWIs helps the Department of Buildings (DOB) ensure that inspectors have sufficient knowledge and experience to accurately inspect exterior walls.

QEWIs have new responsibilities, too. No longer can a QEWI delegate the inspection to tradesmen and technicians; only architects, engineers, and individuals with a bachelor’s degree in architecture or engineering and three years of FISP experience – or those without a degree who have at least five years of FISP experience – can perform inspection tasks, and then only under a QEWI’s direct supervision. These new requirements are bound to increase costs for owners, who now must retain more a highly credentialed and experienced FISP team.

Close-up Inspection Intervals Mandated

Previously, close-up inspection from scaffolding or other platforms was required for “a representative sample” of the exterior wall (minimum one physical examination), as determined by the QEWI. No longer. The rule now specifies that close-up inspections must be performed at least every 60 feet along the length of every exterior wall fronting a public right-of-way (not just street fronts, but now also sidewalks, easements, plazas, and other public places). The QEWI’s discretion is reserved for determining which locations along those walls are “most deleterious,” and performing the examinations there.

Some expressed interest in seeing the DOB allow the use of drones to facilitate close-up inspections. The amended rule dismisses these suggestions, stating unequivocally that the use of drones and high-resolution photography may not take the place of a hands-on inspection.

The new close-up inspection requirements are big news, as they likely mean more time and expense to meet the minimum number of physical examinations. However, with aging, fragile materials like the terra cotta that recently killed a pedestrian, even these more stringent requirements may not be enough. At the public hearing for the rule, some called for 100% hands-on inspection of terra cotta, an ambitious and costly proposal that may nonetheless become part of the rule in the future.

Cavity Wall Probes Now Required

The other big news in Cycle 9 is the requirement for cavity wall probes. Starting this cycle, and in every odd-numbered cycle thereafter, probes must be performed on all cavity wall construction. At a minimum, a probe must be completed along each required close-up inspection interval, with the QEWI ultimately determining the number, size, and location of the probes to best identify the condition and spacing of wall ties.

Exceptions to this requirement include buildings that underwent cavity wall rehabilitation, specifically addressing wall ties, within the past ten years; new buildings less than ten years old for which evidence of wall tie installation is provided; or buildings for which an alternative method of evaluating wall ties is proposed by the QEWI and accepted by the DOB.

The impetus for this new provision is clear: recent failures of cavity walls due to missing or deficient ties. Still, the destructive nature of invasive probes should not be taken lightly. Punching holes in the façade every 60 feet is no small thing, and historic buildings may need additional permitting from the Landmarks Preservation Commission. Sidewalk protection will need to be erected, and relevant permits obtained. For large buildings where the cumulative area of probes exceeds 150 sf of masonry, RCNY §101-14 requires a work permit. Finding a contractor to undertake this work when thousands of buildings are under the gun to meet filing deadlines may also be a significant consideration.

SWARMP and Unsafe Condition Categories Clarified

To better distinguish Safe with a Repair and Maintenance Program (SWARMP) conditions from Unsafe ones, the new rule specifies that conditions requiring repair or maintenance within one year must be considered Unsafe, while those that need to be addressed in the next five years – but not less than one year – should be classified as SWARMP.

Reports Must Include New Information

The critical examination report must specify not only the age and type of construction, but also “all materials present in the exterior wall,” which could prove a challenge. The rule provides specific distress conditions to be described in the report, ranging from cracking and displacement to loosening of metal anchors and water infiltration, and now requires the location diagram to include dimensions for each façade elevation. All significant conditions must now be documented with photographs that are mapped to key plans, elevations, and locator drawings.

The time frame by which Unsafe and SWARMP conditions must be addressed can no longer be a general month and year. Instead, the QEWI must provide an exact date by which work must be completed. For Unsafe conditions, time frames of more than five years are not acceptable.

QEWI selfies will now appear in reports, as dated photo documentation of QEWIs (and their staff) performing close-up inspections is required.

Other new photography requirements include:

- Elevation photos;

- Detailed condition photos of all SWARMP and Unsafe conditions, labeled with status designation and mapped on the building façade;

- Typical condition photos for buildings classified as Safe; and

- Cavity wall probe photos for each opening, including measurement and spacing of wall ties, close-ups of wall tie type and installation, and condition of relieving angles and substrate.

With phone cameras making high-resolution photography simple, the new rule demands comprehensive documentation of every detail. The advantage of this photographic record is that those who review reports in the future need not rely solely on interpretation, as the evidence for finding conditions deleterious – or not – will be clearly illustrated.

Public Protection Measures Added

Not only must QEWIs identify the location of Unsafe conditions, they are now specifically charged with advising the owner of the appropriate protective measures, including recommended type and location of public protection – and reporting these recommendations to the DOB.

New Requirements for Correcting Unsafe Conditions

To give owners enough time to make repairs, the updated rule extends the 30-day period for correcting Unsafe conditions to 90 days. And owners may have even longer: if, due to the scope of repairs, an Unsafe condition cannot be corrected in that time, the QEWI may recommend an extended time frame (not more than five years). If owners can’t meet the deadline, they must notify the DOB and provide supporting documents from the QEWI in a subsequent report justifying the delay.

Corrections made in the previous cycle will now need to be reported as Unsafe if they need further or repeated repair at the time of the Cycle 9 inspection. This new stipulation aims to close the loophole on conditions that are barely stabilized through multiple “band-aid” repairs.

Increase in Civil Penalties for Noncompliance

Penalties receive a big boost in the new version of the rule, so there is more incentive for owners to comply. Failing to file an acceptable inspection report now means a civil penalty of $5,000, a five-fold increase over previous cycles. Owners who file late incur a penalty of $1,000 per month, four times the $250-per-month penalty of the last cycle.

In addition, owners who fail to correct Unsafe conditions are liable for a $1,000-per-month penalty, plus a monthly fine for each linear foot of sidewalk shed, starting at $10 per linear foot of shed per month after the first year, and increasing each year thereafter, up to $40/lf/month in year five. Keeping sidewalk sheds up for years is a poor solution to façade hazards, so the updated rule aims to motivate owners to take down sheds – and properly address Unsafe conditions – as quickly as possible.

Failing to correct a SWARMP condition from the previous cycle, so it must be filed as Unsafe this cycle, now carries a penalty of $2,000.

In anticipation of natural disasters, a new stipulation waives penalties if a state of emergency is declared that prevents the owner from conducting an inspection, filing a report, or correcting Unsafe conditions.

Owners Must Post Building Façade Status in the Lobby

Like restaurant health grades, façade condition status must now be posted in the lobby or vestibule of the building, within 30 days of issuance. Having to prominently display a certificate announcing the building status as “Unsafe” might be just the motivator an owner needs to make needed repairs promptly. At least, that’s the City Council’s hope.

Continuation of Staggered Filing Windows

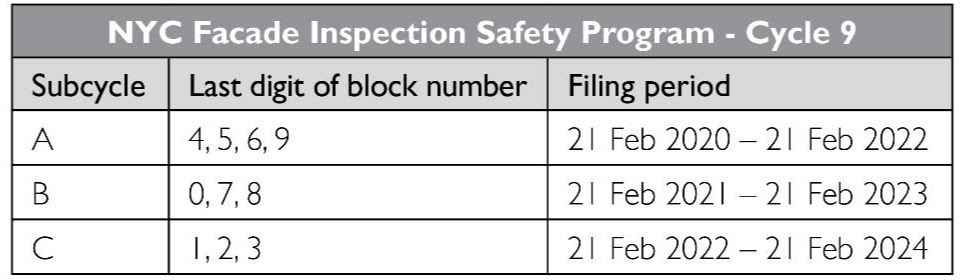

Beginning with Cycle 7 in 2010, the DOB instituted staggered filing windows. For Cycle 9, the report deadlines are as follows:

Take-Home Message for Building Owners

With penalties at four and five times what they were in the last cycle, and the reputation of a building hanging in the balance, the incentive to inspect thoroughly, file on time, and make repairs within the allotted time frame couldn’t be more clear. The New York City Council – and city residents – are worn down by reports of citizens struck by flying façade debris, and the drive to make buildings safer has reached a tipping point.

Owners should act now to:

- Make sure the FISP inspector meets the new QEWI requirements.

- Address remaining Unsafe and SWARMP conditions from Cycle 8.

- Determine the Cycle 9 filing deadline based on the block number.

- Plan for additional drops to meet close-up inspection requirements.

- Budget for exploratory probes, if the building has cavity walls.

- Allow additional time to arrange for lifts, scaffolding, sidewalk bridging, and contractors as part of the inspection process.

New York wasn’t the first U.S. city to enact façade inspection legislation (that honor goes to Chicago), but with more than 14,500 buildings covered by the rule, it tops the nation in mandated exterior wall evaluations. Those inspections are only as effective as the repairs and maintenance plans they engender, and New York is motivated to make those corrections happen.

Related Stories

| Mar 11, 2011

Chicago office building will serve tenants and historic church

The Alter Group is partnering with White Oak Realty Partners to develop a 490,000-sf high-performance office building in Chicago’s West Loop. The tower will be located on land owned by Old St. Patrick’s Church (a neighborhood landmark that survived the Chicago Fire of 1871) that’s currently being used as a parking lot.

| Mar 11, 2011

Community sports center in Nashville features NCAA-grade training facility

A multisport community facility in Nashville featuring a training facility that will meet NCAA Division I standards is being constructed by St. Louis-based Clayco and Chicago-based Pinnacle.

| Mar 11, 2011

Slam dunk for the University of Nebraska’s basketball arena

The University of Nebraska men’s and women’s basketball programs will have a new home beginning in 2013. Designed by the DLR Group, the $344 million West Haymarket Civic Arena in Lincoln, Neb., will have 16,000 seats, suites, club amenities, loge, dedicated locker rooms, training rooms, and support space for game operations.

| Mar 10, 2011

Steel Joists Clean Up a Car Wash’s Carbon Footprint

Open-web bowstring trusses and steel joists give a Utah car wash architectural interest, reduce its construction costs, and help green a building type with a reputation for being wasteful.

| Mar 10, 2011

How AEC Professionals Are Using Social Media

You like LinkedIn. You’re not too sure about blogs. For many AEC professionals, it’s still wait-and-see when it comes to social media.

| Mar 9, 2011

Hoping to win over a community, Facebook scraps its fortress architecture

Facebook is moving from its tony Palo Alto, Calif., locale to blue-collar Belle Haven, and the social network want to woo residents with community-oriented design.

| Mar 9, 2011

Winners of the 2011 eVolo Skyscraper Competition

Winners of the eVolo 2011 Skyscraper Competition include a high-rise recycling center in New Delhi, India, a dome-like horizontal skyscraper in France that harvests solar energy and collects rainwater, and the Hoover Dam reimagined as an inhabitable skyscraper.

| Mar 9, 2011

Igor Krnajski, SVP with Denihan Hospitality Group, on hotel construction and understanding the industry

Igor Krnajski, SVP for Design and Construction with Denihan Hospitality Group, New York, N.Y., on the state of hotel construction, understanding the hotel operators’ mindset, and where the work is.

| Mar 3, 2011

HDR acquires healthcare design-build firm Cooper Medical

HDR, a global architecture, engineering and consulting firm, acquired Cooper Medical, a firm providing integrated design and construction services for healthcare facilities throughout the U.S. The new alliance, HDR Cooper Medical, will provide a full service design and construction delivery model to healthcare clients.

| Mar 2, 2011

Design professionals grow leery of green promises

Legal claims over sustainability promises vs. performance of certified green buildings are beginning to mount—and so are warnings to A/E/P and environmental consulting firms, according to a ZweigWhite report.