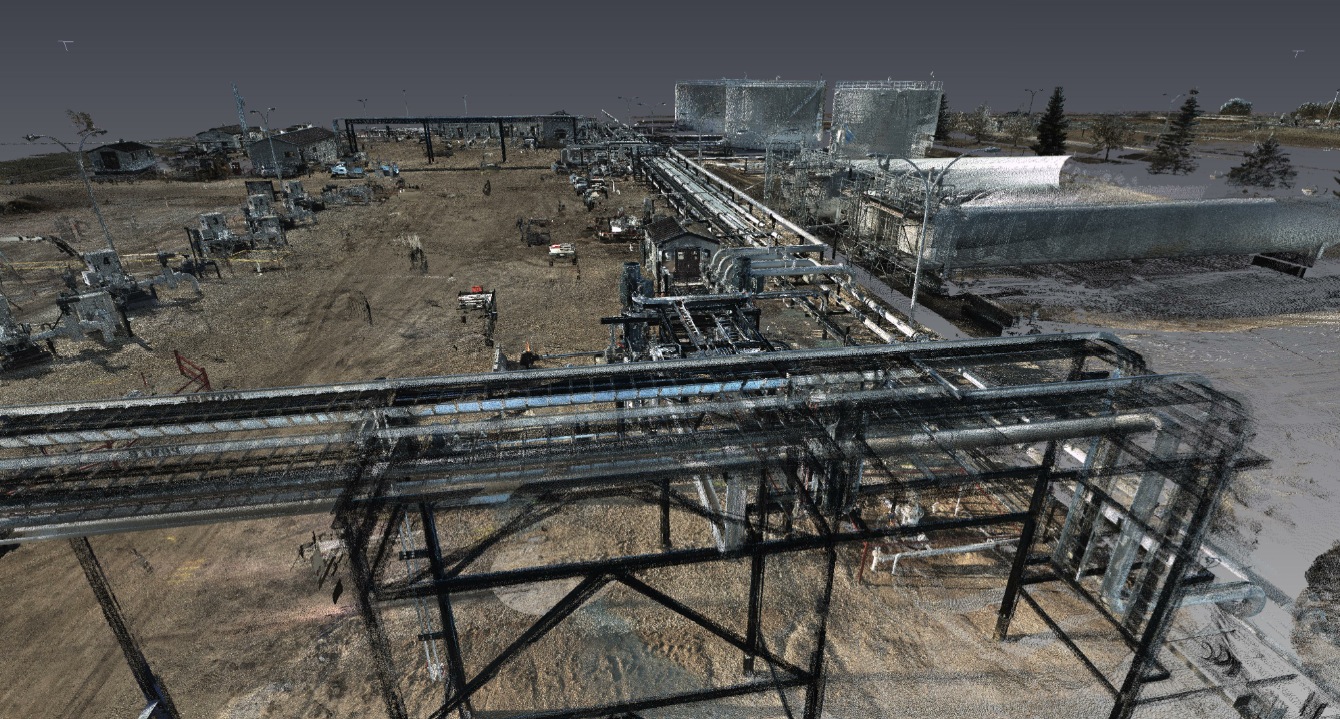

When the engineering/architecture firm SSOE performed laser scanning for projects in the past, it was always client driven. The scanning, data processing, and modeling were done only when customers demanded them.

But about two years ago, the firm “took a leap of faith,” recalls its Technology Leader Mark LaBell, when he convinced his boss to approve a $2,500 one-day scan. Since then, SSOE has made a deeper dive into this service by significantly increasing its investments in servers, computers, and personnel training, and widening the network of third-party scanning companies it uses.

The result, says LaBell, “has been a fire hose” of client interest. As of late January, SSOE had 16 projects that were either being scanned or for which laser scanning was part of the proposal. “That’s just in the last six weeks,” says LaBell. He estimates the firm will deploy laser scanning on 75 projects this year.

Coverage of 3D Laser Scanning brought to you by:

Laser scanning has become an essential reality-capture tool and competitive advantage for a growing number of AEC firms. It provides an extra layer of quality control and accuracy, and allows firms to expand their portfolios.

Linn Bjornrud, AIA, Associate and BIM Manager with Leo A Daly, says his firm has clients that are conducting scientific studies deep within the Earth, “and we have architecture we need to build there that, prior to laser scanning, would have been quite a feat to accomplish.”

Ryan Martin, AIA, NCARB, Leo A Daly’s Director of Design–Hospitality Architecture, adds that laser scanning is useful when renovating and repositioning a building above ground, too. On one such hospitality project in Colorado, Leo A Daly scanned the exterior to view the building from all angles, “and take off dimensions as we work through design issues,” says Martin.

Increasingly, AEC firms are using laser scanning as a risk management tool, says Matthew Daly, Regional Manager–Western U.S. for FARO Technologies, a supplier of scanning equipment and software. He elaborates that a contractor might scan concrete as it’s being pored, or steel as it’s being erected, to track the integrity of the materials and their installation before the next construction phase proceeds.

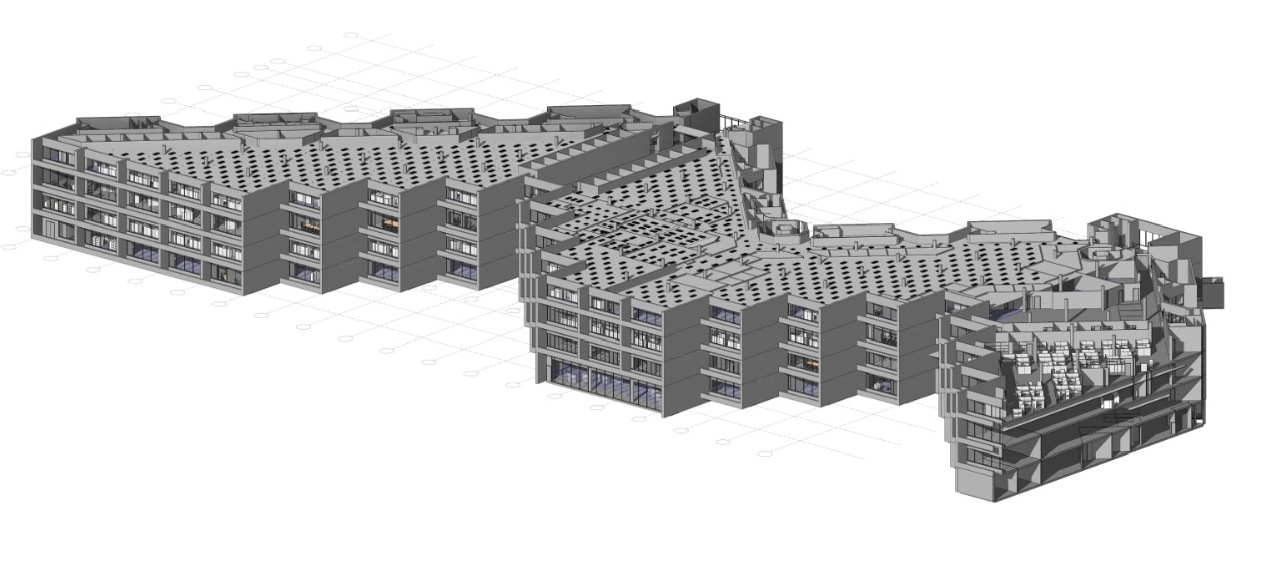

The utility of laser scanning was demonstrated recently when AE firm Nelson scanned the entire 700,000 sf of Prudential’s headquarters in Minneapolis, Minn., for a major renovation project. Nelson used scans to confirm the original blueprints’ dimensions and positioning. Image courtesy Nelson.

The utility of laser scanning was demonstrated recently when AE firm Nelson scanned the entire 700,000 sf of Prudential’s headquarters in Minneapolis, Minn., for a major renovation project. Nelson used scans to confirm the original blueprints’ dimensions and positioning. Image courtesy Nelson.

OUTSOURCE OR IN-HOUSE?

WD Partners owns its scanning hardware and software, which amounts to a six-figure cost proposition, says Andrew Maletz, AIA, NCARB, LEED AP, Executive Vice President. The number of projects it scans justifies the cost, he explains. But the first cost for the equipment and software definitely makes other firms think twice about committing more fully to scanning technology.

Over the past five years, Nelson has bought a few scanners. But it prefers to draw upon a network of certified scanning providers it has developed by region. The difficulty of outsourcing laser scanning, though, is establishing standards, says Brandon Pike, Nelson’s Strategic Manager, BIM Services. His firm also prefers providers that can deliver BIM models from scan data.

Daly counters that the price of scanning and data processing has come down in recent years. FARO’s scanners run around $60,000, and Daly says AEC firms are using this equipment for a variety of projects, including hospital construction and renovation, and commercial building rehabs.

Scanning comes in handy when firms don’t have access to a building’s original documents, or question the accuracy of legacy documents. “Understanding what’s going on with the floors is a big reason for using scanners,” says Daly.

He and other AEC experts point out that laser scanning often shows walls inside buildings that aren’t plumb. “So interpretation needs to happen” for design purposes, says Leo A Daly’s Bjornrud. “The question, then, is how many points of interpretation are there between the scans and when we get the product?”

It’s the very objectivity of scanned data that Maletz of WD Partners thinks is laser scanning’s biggest value. “With handheld methods, there is often a degree of subjectivity and interpretation required when analyzing existing conditions.”

Laser scanning captures huge amounts of data; so much so, in fact, that scan files can overwhelm a firm’s servers. It can take months to corral and manipulate this information for modeling purposes. Maletz says that while there are more software tools that help streamline this conversion, “the process is not yet automated, and those who consider reality capture need to have a well-thought-out BIM execution plan.”

SSOE’s LaBell says his firm has been using Autodesk’s ReCap software to make laser-scanning data easier to work with. He says SSOE is currently involved in an ongoing project for which seven of its offices have been sharing 500-plus gigabytes of scanned data.

“We can edit the point cloud to engineer around the things that weren’t going to be there” after construction, says LaBell. That data could be edited for use with Revit, CAD, or other modeling software.

Because this process reduces time and expenses, “we have been able to go after projects more aggressively, with the promise that the design and engineering would be quicker,” he says.

APPS HELP CAPTURE REAL, VIRTUAL IMAGES

As laser scanning is more widely used, AEC firms are also weighing the pros and cons of other tools that capture and augment real images, or create virtual realities.

Daqri recently launched an updated version of its Smart Helmet for commercial use. The high-tech hardhat features a 4D visor that relies heavily on the Internet of Things and a sensor and camera array to provide users with the means to analyze and detect objects from the worker’s surroundings.

Nelson and Clark Nexsen are among the firms that are evaluating software and apps, such as Trimble’s Project Tango, Matterport, and DotProduct’s Phi.3D, which run on professional-grade or mobile devices to capture 3D images and video of rooms on the fly. These tools allow users to augment and convert that data into 3D models.

The gaming industry seems to be the starting point for many of the AR and VR options that AEC firms are eyeing. Last year, Autodesk launched a game engine called Stingray, derived from an engine called Bitsquid, which Autodesk acquired in 2014. VIMtrek has licensed gaming software for AEC usage: a Revit add-on called Producer that quickly converts project files into 3D environments; and Viewer, which allows users to navigate around that environment as if they were moving through a video game.

Daly believes that as demand for more immersive visual experiences increases, so will the demand for laser scanning that, “can still provide the highest-quality reality-capture data.”

Related Stories

AEC Tech | Jan 8, 2020

Thornton Tomasetti launches open-source embodied carbon measurement tool

Beacon is a Revit plugin that generates a comprehensive data visualization of a project’s embodied carbon.

| Dec 18, 2019

Reconsidering construction robotics

After decades when experts predicted that robots would become more prevalent on construction sites, it would appear that the industry has finally reached that point where necessity, aspiration, and investment are colliding.

Big Data | Dec 4, 2019

AEC data's coming out party

AEC firms are finally putting to use project information they’ve been storing in their computers for years.

AEC Tech | Oct 30, 2019

Robot masons work with humans on a $52 million housing project in Illinois

The machines address trade labor shortages, as well as worker wellbeing and safety.

AEC Tech | Oct 29, 2019

Bluebeam launches Revu 2019, with accelerated rendering and enhanced measurement functionality

The latest version of the company's flagship tool focuses on accuracy, speed, standardization.

AEC Tech | Sep 27, 2019

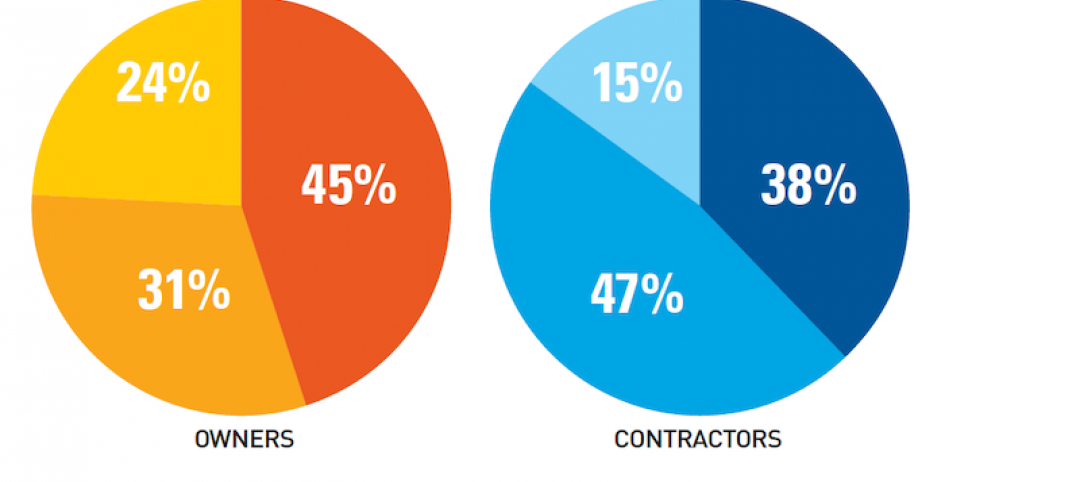

Dual, often incompatible, management systems add work and cost to projects

A new survey finds that contractors and owners differ about the urgency of getting to single, seamless platforms.

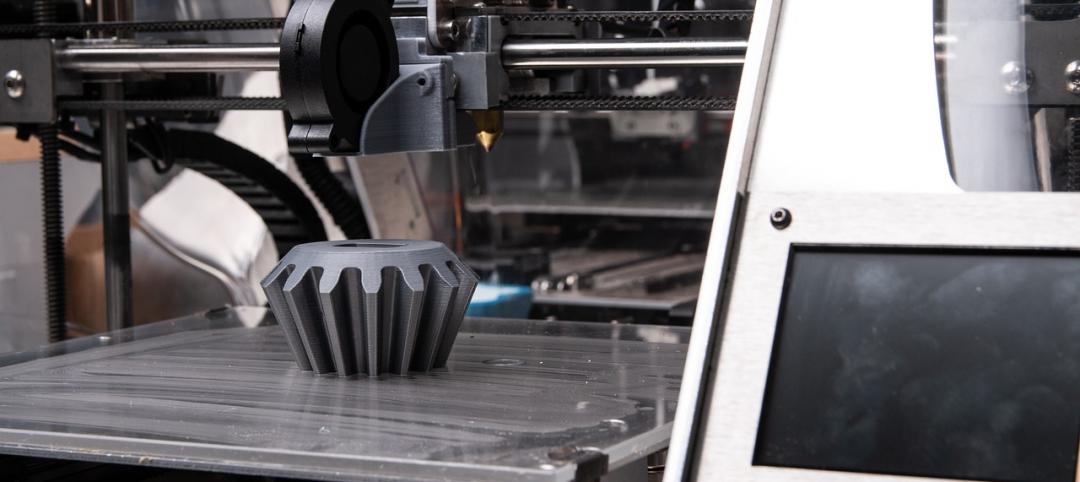

3D Printing | Sep 17, 2019

Additive manufacturing goes mainstream in the industrial sector

More manufacturers now include this production process in their factories.

Multifamily Housing | Sep 12, 2019

Meet the masters of offsite construction

Prescient combines 5D software, clever engineering, and advanced robotics to create prefabricated assemblies for apartment buildings and student housing.

AEC Innovators | Aug 27, 2019

7 AEC industry disruptors and their groundbreaking achievements

From building prefab factories in the sky to incubating the next generation of AEC tech startups, our 2019 class of AEC Innovators demonstrates that the industry is poised for a shakeup. Meet BD+C’s 2019 AEC Innovators.

AEC Tech | Aug 25, 2019

Deluxe parking: A condo building in Philadelphia offers its owners a completely automated parking service

This is the first “palletless” system that Westfalia Technologies has installed.