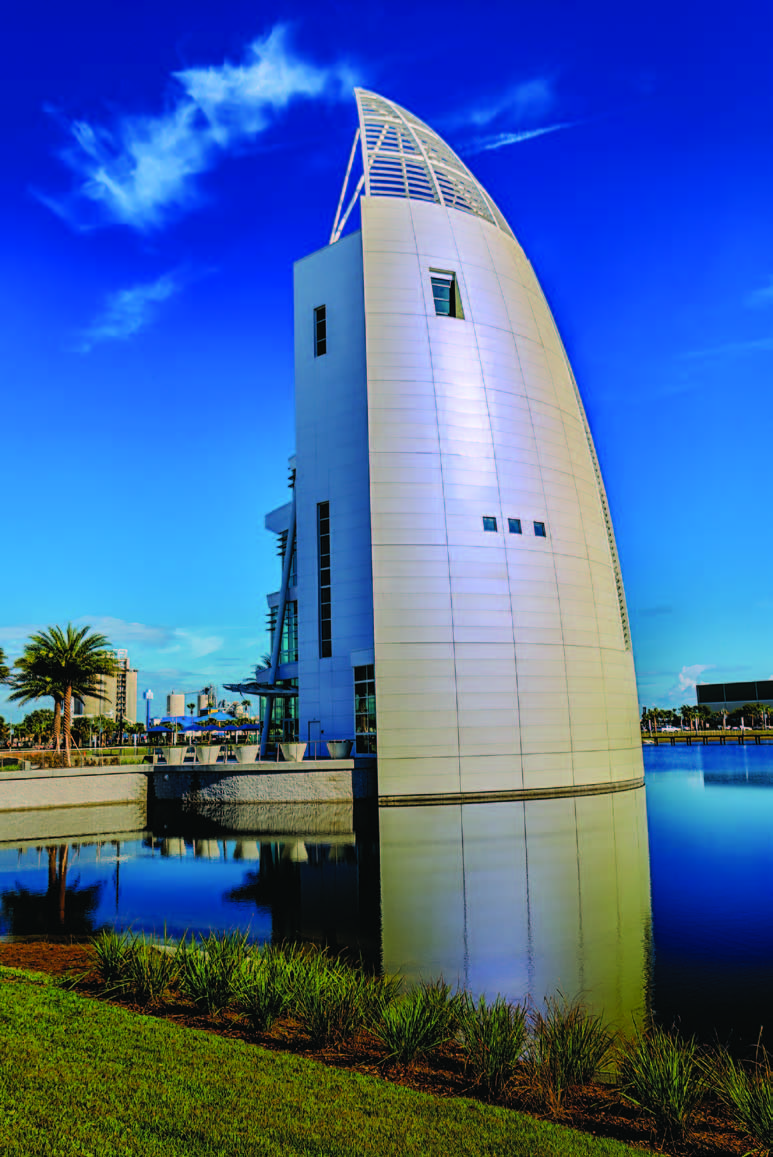

With its shimmering, iridescent exterior, Exploration Tower at Port Canaveral, Fla., beckons visitors with its unique appearance as its color changes in different light and at different angles.

Opened in November 2013, the Port’s iconic welcome center showcases the first use of Valspar’s new Kameleon™ Color mica coating as spray-applied to Firestone Metal Products’ UNA-CLAD™ metal wall panels by Linetec, one the nation’s largest finishers of architectural aluminum.

An integral part of Florida’s Space Coast and Canaveral Cove’s revitalization, Exploration Tower is owned by Canaveral Port Authority. Its opening coincided with the Port’s 60th anniversary of its establishment and the 500th anniversary of Ponce de Leon’s landing on Florida’s east coast.

Taking its cues from the shapes and hues of the port, GWWO Inc./Architects designed the $23 million, seven-story, sail-shaped structure to express the common characteristics of “transience, function and imagery.” The building’s southern elevation soars from the water to the sky. It narrows in scale and reduces its exterior coverage until only the steel frame remains to outline the curvature and comes together at a peak 60-feet above the main roof level.

The architects elaborate, “The building’s dynamic form and features – sun louvers, exposed structure and iridescent skin -- contribute to a constant sense of movement as the sun plays across the structure, meet functional needs, and evoke imagery of the Port and [Brevard] County. A rocket ready to launch, a surfboard in the sand, a ship’s hull, a rocket contrail; all can be seen in the structure’s striking presence.”

Skanska USA served as the general contractor of the 23,000-sf project. Kenpat USA was the subcontractor responsible for the exterior metal façades and wall system. Working closely with Kenpat, Firestone engineered and fabricated the façade’s metal panel system.

Radius Track Corporation fabricated the curved structural faming and provided the 3-D building information modeling (BIM) to coordinate the connection points for each panel in the building’s parabolic curve. In total, Kenpat installed 42 pre-fabricated structural panelized units as sub-structure for the cladding, with the largest being 36 feet by 10 feet.

GWWO selected Valspar’s Blue Pearl II color-changing paint to capture the themes of revitalization and change it sought to represent for the Port Canaveral area. Along with its unique appearance, the finish must withstand Florida’s hurricane wind speeds, unrelenting sun and salt spray.

Kameleon Colors offer the same, advanced protection as Valspar’s 70% PVDF Fluropon® product family in rich, pearlescent pigments that shift in color when viewed from different angles. Applied in a three-coat system, Kameleon colors consist of a primer, basecoat and color coat, and are available for both extrusion and coil products.

“When creating a unique design that requires a vibrant color scheme, Kameleon Color is an excellent choice. This innovative, multicolored system uses mica flakes to create a consistent, iridescent look,” notes Tim Tritch, Valspar’s director of sales. The coating utilizes a blend of ceramic and inorganic pigments create this rich look that is both brilliant and subtle.”

Linetec also applied a clear coat over the Blue Pearl II for enhanced durability. As with other 70% PVDF resin-based coatings, Kameleon Colors meet the most stringent, exterior, architectural specification, American Architectural Manufacturers Association’s AAMA-2605. This specification requires paint coatings to meet rigorous testing performance standards, including more than 2,000 hours of cyclic corrosion per ASTM G85 annex 5, and heat- and humidity-resistance. Per AAMA-2605, the coating also must maintain its film integrity, color retention, chalk resistance, gloss retention, and erosion resistance properties for a minimum of 10 years on the South Florida testing site.

“If anyone can spray this and make it look good, it would be Linetec,” said GWWO’s senior associate, John Gregg, AIA, LEED AP, AVS, during a project planning meeting.

Accepting the praise with confidence, Linetec’s paint plant manager Paul Bratz says, “No one has sprayed this before, but our knowledgeable staff was up to the challenge. There was some trial and error during the process. It was critical that each paint run maintained the same parameters. The spray conditions, paint prep and application consistency of the paint itself were all critical. The slightest change could alter the look of the paint.”

To ensure consistency and minimize variation, Linetec modified its existing paint protocol process. Bratz explains, “The amount of paint needed for the entire project was determined and ordered as a single batch at the beginning of the project. Valspar prepared the special mica technology paint all at one time with excellent consistency, taking out the variable of multiple paint batches.”

In addition to the Kameleon Colors’ Blue Pearl II finish on southern seaside elevation, Linetec also applied Valspar’s Fluropon White finish to the northern elevation’s aluminum-framed curtainwall offering views of the bustling port. The entire project was painted in four phases, starting in March 2013 and ending in May.

Owner: Canaveral Port Authority

Master planning: AECOM, GWWO Inc./Architects

Architect: GWWO Inc./Architects

General contractor: Skanska USA Building

Structural engineer: Thornton Tomasetti

Exterior cladding system – installing contractor: KENPAT USA LLC

Exterior cladding system – manufacturer: Firestone Metal Products

Exterior cladding system – 3-D modeling: Radius Track Corporation

Exterior cladding system – coatings manufacturer: The Valspar Corporation

Exterior cladding system – finisher: Linetec

Related Stories

| Aug 11, 2010

Utah research facility reflects Native American architecture

A $130 million research facility is being built at University of Utah's Salt Lake City campus. The James L. Sorenson Molecular Biotechnology Building—a USTAR Innovation Center—is being designed by the Atlanta office of Lord Aeck & Sargent, in association with Salt-Lake City-based Architectural Nexus.

| Aug 11, 2010

San Bernardino health center doubles in size

Temecula, Calif.-based EDGE was awarded the contract for California State University San Bernardino's health center renovation and expansion. The two-phase, $4 million project was designed by RSK Associates, San Francisco, and includes an 11,000-sf, tilt-up concrete expansion—which doubles the size of the facility—and site and infrastructure work.

| Aug 11, 2010

Goettsch Partners wins design competition for Soochow Securities HQ in China

Chicago-based Goettsch Partners has been selected to design the Soochow Securities Headquarters, the new office and stock exchange building for Soochow Securities Co. Ltd. The 21-story, 441,300-sf project includes 344,400 sf of office space, an 86,100-sf stock exchange, classrooms, and underground parking.

| Aug 11, 2010

New hospital expands Idaho healthcare options

Ascension Group Architects, Arlington, Texas, is designing a $150 million replacement hospital for Portneuf Medical Center in Pocatello, Idaho. An existing facility will be renovated as part of the project. The new six-story, 320-000-sf complex will house 187 beds, along with an intensive care unit, a cardiovascular care unit, pediatrics, psychiatry, surgical suites, rehabilitation clinic, and ...

| Aug 11, 2010

Colonnade fixes setback problem in Brooklyn condo project

The New York firm Scarano Architects was brought in by the developers of Olive Park condominiums in the Williamsburg section of Brooklyn to bring the facility up to code after frame out was completed. The architects designed colonnades along the building's perimeter to create the 15-foot setback required by the New York City Planning Commission.

| Aug 11, 2010

Wisconsin becomes the first state to require BIM on public projects

As of July 1, the Wisconsin Division of State Facilities will require all state projects with a total budget of $5 million or more and all new construction with a budget of $2.5 million or more to have their designs begin with a Building Information Model. The new guidelines and standards require A/E services in a design-bid-build project delivery format to use BIM and 3D software from initial ...

| Aug 11, 2010

Opening night close for Kent State performing arts center

The curtain opens on the Tuscarawas Performing Arts Center at Kent State University in early 2010, giving the New Philadelphia, Ohio, school a 1,100-seat multipurpose theater. The team of Legat & Kingscott of Columbus, Ohio, and Schorr Architects of Dublin, Ohio, designed the 50,000-sf facility with a curving metal and glass façade to create a sense of movement and activity.

| Aug 11, 2010

Residence hall designed specifically for freshman

Hardin Construction Company's Austin, Texas, office is serving as GC for the $50 million freshman housing complex at the University of Houston. Designed by HADP Architecture, Austin, the seven-story, 300,000-sf facility will be located on the university's central campus and have 1,172 beds, residential advisor offices, a social lounge, a computer lab, multipurpose rooms, a fitness center, and a...