More owners and developers are latching onto design-build as a preferred delivery method for projects large and small. And a new paper from FMI, the construction management consultant and investment banking firm, outlines how AEC firms and their clients that enter into such contracts are avoiding stress points that often bog down construction.

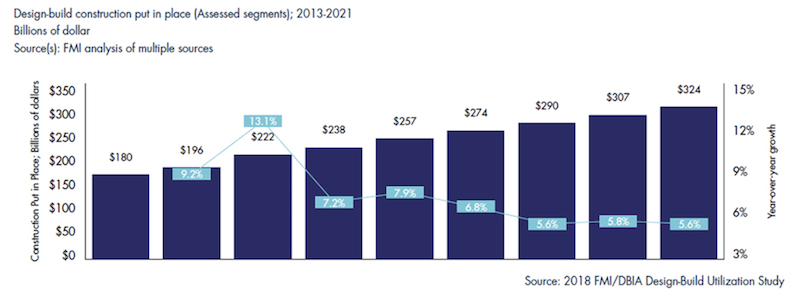

Drawing on FMI’s “2018 Design-Build Utilization” report, “the paper, “The Growing World of Design-Build,” written by FMI senior consultant Paul Trombitas, estimates that design-build project delivery will increase by 18% between 2018 and 2021, and comprise 44% of total construction spending, or the equivalent of $1.19 trillion over that four-year span.

A sustained emphasis toward educating owners and project stakeholders on the process and benefits associated with design-build has facilitated continued adoption and greater utilization industrywide. On the public side, increased design-build legislation has helped push the adoption of such projects. On the private side, owners tend to select design-build for unique and challenging projects that require lots of collaboration.

Design-build is projected to account for 44% of all construction spending for the years 2018 through 2021. Image: FMI

Design-build is projected to account for 44% of all construction spending for the years 2018 through 2021. Image: FMI

Of the various customer segments that use design-build, manufacturing, road infrastructure, and education will represent the greatest percentage of design-build construction spending over the next three years, states FMI.

In addition to larger and more complex projects, design-build continues to expand into project sizes of less than $25 million, as owners continue to gain exposure to the benefits of the delivery method.

However, design-build has its own set of challenges that, according to FMI principal Bill Spragins, revolve around the differing roles assumed by the parties, the number of decisions that must be made simultaneously, and the increased speed of decision-making associated with compression of the design and construction cycle.

For example, a project is potentially set up fail when owners confine their use of this delivery method to procurement without aligning the decision-making and approval processes within the organization to meet scheduling needs. A project can also be derailed by misaligned expectations between the owner and design-builder regarding the level of control that the owner’s team retains over design decisions.

Consequently, for a design-build delivery method to work, specific parameters need to be established about project scope, scheduling, and who’s responsible for what.

FMI states that AEC firms looking to win design-build projects need to think strategically: What slices of the market are they targeting, who are the right customers, what services do they need, and how do these offerings set a firm apart from its competition?

FMI recommends that AEC firms take a customer-focused approach when trying to win design-build contracts. Image: FMI

FMI uses a “4C model” to illustrate the context of profitable growth. Its starts with defining the business “climate” that the AEC firm is operating in—from demographics to regulations—and then digging deeper into possible changes, expectations, and needs of customers

AEC firms need to find out what criteria owners use to select contractors. They also need to weigh their own strengths and weaknesses against competitors’ for a given project.

FMI singles out a number of steps for winning design-build projects:

•Build a compelling story about why your firm is right for the project

•Build a go-to-market strategy that defines customers before an RFP hits the street

•Think like a customer

•Find out what the customer wants and why it’s important.

•Put your time where your strategy is. Build in organizational capacity that’s centered on a key focus, such as spending time with customers in advance.

The paper provides some avenues for minimizing stress points that can arise during a design-build contract. Having early and continued alignment among all project owners and stakeholders can help remove or limit these issues.

Make sure you completely understand requirements or other bidding assumptions, particularly on design-build projects. Of the projects FMI studied, 25% fell victim to this. At times, even the owner won’t understand the true impact of some of the requirements that are written into the contract.

Make sure there are formal internal hand-off meeting(s) between estimating/preconstruction and project management/field operations. This should include subcontractor involvement in planning the work.

Within the design-build arena, public-private partnerships (P3s) have emerged as a way for public and private sector entities to align on the provision of assets and the delivery of services and then effectively manage that partnership. To assemble the most successful P3 project teams, contractors should:

•Build your expertise through strategic joint ventures. Pick your partners carefully.

•Plan comprehensively for project complexities. Be smart about your business decisions.

•Understand the cost and risk barriers to entry. You need deep pockets and a thick skin.

•Have a deep understanding of an owner’s “ecosystem.”

•Start building relationships with public officials and finance representatives now.

•Collaborate and innovate.

Related Stories

| Aug 11, 2010

Special Recognition: Triple Bridge Gateway, Port Authority Bus Terminal New York, N.Y.

Judges saw the Triple Bridge Gateway in Midtown Manhattan as more art installation than building project, but they were impressed at how the illuminated ramps and bridges—14 years in the making—turned an ugly intersection into something beautiful. The three bridges span 9th Avenue at the juncture where vehicles emerge from the Lincoln Tunnel heading to the Port Authority of New Yor...

| Aug 11, 2010

World's tallest all-wood residential structure opens in London

At nine stories, the Stadthaus apartment complex in East London is the world’s tallest residential structure constructed entirely in timber and one of the tallest all-wood buildings on the planet. The tower’s structural system consists of cross-laminated timber (CLT) panels pieced together to form load-bearing walls and floors. Even the elevator and stair shafts are constructed of prefabricated CLT.

| Aug 11, 2010

Setting the Green Standard For Community Colleges

“Ohlone College Newark Campus Is the Greenest College in the World!” That bold statement was the official tagline of the festivities surrounding the August 2008 grand opening of Ohlone College's LEED Platinum Newark (Calif.) Center for Health Sciences and Technology. The 130,000-sf, $58 million community college facility stacks up against some of the greenest college buildings in th...

| Aug 11, 2010

School Project Offers Lessons in Construction Realities

Imagine this scenario: You're planning a $32.9 million project involving 112,000 sf of new construction and renovation work, and your job site is an active 32-acre junior-K-to-12 school campus bordered by well-heeled neighbors who are extremely concerned about construction noise and traffic. Add to that the fact that within 30 days of groundbreaking, the general contractor gets canned.

| Aug 11, 2010

CityCenter Takes Experience Design To New Heights

It's early June, in Las Vegas, which means it's very hot, and I am coming to the end of a hardhat tour of the $9.2 billion CityCenter development, a tour that began in the air-conditioned comfort of the project's immense sales center just off the famed Las Vegas Strip and ended on a rooftop overlooking the largest privately funded development in the U.

| Aug 11, 2010

University of Arizona College of Medicine

The hope was that a complete restoration and modernization would bring life back to three neoclassic beauties that formerly served as Phoenix Union High School—but time had not treated them kindly. Built in 1911, one year before Arizona became the country's 48th state, the historic high school buildings endured nearly a century of wear and tear and suffered major water damage and years of...

| Aug 11, 2010

Top of the rock—Observation deck at Rockefeller Center

Opened in 1933, the observation deck at Rockefeller Center was designed to evoke the elegant promenades found on the period's luxury transatlantic liners—only with views of the city's skyline instead of the ocean. In 1986 this cultural landmark was closed to the public and sat unused for almost two decades.

| Aug 11, 2010

200 Fillmore

Built in 1963, the 32,000-sf 200 Fillmore building in Denver housed office and retail in a drab, outdated, and energy-splurging shell—a “style” made doubly disastrous by 200 Fillmore's function as the backdrop for a popular public plaza and outdoor café called “The Beach.

| Aug 11, 2010

Integrated Project Delivery builds a brave, new BIM world

Three-dimensional information, such as that provided by building information modeling, allows all members of the Building Team to visualize the many components of a project and how they work together. BIM and other 3D tools convey the idea and intent of the designer to the entire Building Team and lay the groundwork for integrated project delivery.

| Aug 11, 2010

High Tech High International used to be a military facility

High Tech High International, reconstructed inside a 1952 Navy metal foundry training facility, incorporates the very latest in teaching technology with a centerpiece classroom known as the UN Theater, which is modeled after the UN chambers in New York. The interior space, which looks more like a hip advertising studio than a public high school, provides informal, flexible seating areas, abunda...