More owners and developers are latching onto design-build as a preferred delivery method for projects large and small. And a new paper from FMI, the construction management consultant and investment banking firm, outlines how AEC firms and their clients that enter into such contracts are avoiding stress points that often bog down construction.

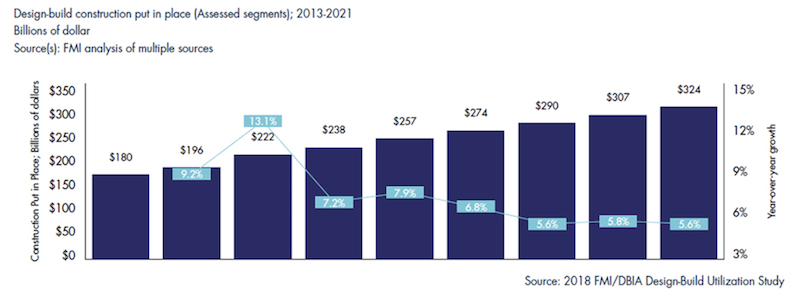

Drawing on FMI’s “2018 Design-Build Utilization” report, “the paper, “The Growing World of Design-Build,” written by FMI senior consultant Paul Trombitas, estimates that design-build project delivery will increase by 18% between 2018 and 2021, and comprise 44% of total construction spending, or the equivalent of $1.19 trillion over that four-year span.

A sustained emphasis toward educating owners and project stakeholders on the process and benefits associated with design-build has facilitated continued adoption and greater utilization industrywide. On the public side, increased design-build legislation has helped push the adoption of such projects. On the private side, owners tend to select design-build for unique and challenging projects that require lots of collaboration.

Design-build is projected to account for 44% of all construction spending for the years 2018 through 2021. Image: FMI

Design-build is projected to account for 44% of all construction spending for the years 2018 through 2021. Image: FMI

Of the various customer segments that use design-build, manufacturing, road infrastructure, and education will represent the greatest percentage of design-build construction spending over the next three years, states FMI.

In addition to larger and more complex projects, design-build continues to expand into project sizes of less than $25 million, as owners continue to gain exposure to the benefits of the delivery method.

However, design-build has its own set of challenges that, according to FMI principal Bill Spragins, revolve around the differing roles assumed by the parties, the number of decisions that must be made simultaneously, and the increased speed of decision-making associated with compression of the design and construction cycle.

For example, a project is potentially set up fail when owners confine their use of this delivery method to procurement without aligning the decision-making and approval processes within the organization to meet scheduling needs. A project can also be derailed by misaligned expectations between the owner and design-builder regarding the level of control that the owner’s team retains over design decisions.

Consequently, for a design-build delivery method to work, specific parameters need to be established about project scope, scheduling, and who’s responsible for what.

FMI states that AEC firms looking to win design-build projects need to think strategically: What slices of the market are they targeting, who are the right customers, what services do they need, and how do these offerings set a firm apart from its competition?

FMI recommends that AEC firms take a customer-focused approach when trying to win design-build contracts. Image: FMI

FMI uses a “4C model” to illustrate the context of profitable growth. Its starts with defining the business “climate” that the AEC firm is operating in—from demographics to regulations—and then digging deeper into possible changes, expectations, and needs of customers

AEC firms need to find out what criteria owners use to select contractors. They also need to weigh their own strengths and weaknesses against competitors’ for a given project.

FMI singles out a number of steps for winning design-build projects:

•Build a compelling story about why your firm is right for the project

•Build a go-to-market strategy that defines customers before an RFP hits the street

•Think like a customer

•Find out what the customer wants and why it’s important.

•Put your time where your strategy is. Build in organizational capacity that’s centered on a key focus, such as spending time with customers in advance.

The paper provides some avenues for minimizing stress points that can arise during a design-build contract. Having early and continued alignment among all project owners and stakeholders can help remove or limit these issues.

Make sure you completely understand requirements or other bidding assumptions, particularly on design-build projects. Of the projects FMI studied, 25% fell victim to this. At times, even the owner won’t understand the true impact of some of the requirements that are written into the contract.

Make sure there are formal internal hand-off meeting(s) between estimating/preconstruction and project management/field operations. This should include subcontractor involvement in planning the work.

Within the design-build arena, public-private partnerships (P3s) have emerged as a way for public and private sector entities to align on the provision of assets and the delivery of services and then effectively manage that partnership. To assemble the most successful P3 project teams, contractors should:

•Build your expertise through strategic joint ventures. Pick your partners carefully.

•Plan comprehensively for project complexities. Be smart about your business decisions.

•Understand the cost and risk barriers to entry. You need deep pockets and a thick skin.

•Have a deep understanding of an owner’s “ecosystem.”

•Start building relationships with public officials and finance representatives now.

•Collaborate and innovate.

Related Stories

| Aug 11, 2010

200 East Brady

Until July 2004, 200 East Brady, a 40,000-sf, 1920s-era warehouse, had been an abandoned eyesore in Tulsa, Okla.'s Brady district. The building, which was once home to a grocery supplier, then a steel casting company, and finally a casket storage facility, was purchased by Tom Wallace, president and founder of Wallace Engineering, to be his firm's new headquarters.

| Aug 11, 2010

Great Solutions: Business Management

22. Commercial Properties Repositioned for University USE Tocci Building Companies is finding success in repositioning commercial properties for university use, and it expects the trend to continue. The firm's Capital Cove project in Providence, R.I., for instance, was originally designed by Elkus Manfredi (with design continued by HDS Architects) to be a mixed-use complex with private, market-...

| Aug 11, 2010

Reaching For the Stars

The famed Griffith Observatory, located in the heart of the Hollywood hills, receives close to two million visitors every year and has appeared in such films as the classic “Rebel Without a Cause” and the not-so-classic “Charlie's Angels: Full Throttle.” Complete with a solar telescope and a 12-inch refracting telescope, multiple scientific exhibits, and one of the world...

| Aug 11, 2010

Holyoke Health Center

The team behind the new Holyoke (Mass.) Health Center was aiming for more than the renovation of a single building—they were hoping to revive an entire community. Holyoke's central business district was built in the 19th century as part of a planned industrial town, but over the years it had fallen into disrepair.

| Aug 11, 2010

The Art of Reconstruction

The Old Patent Office Building in Washington, D.C., completed in 1867, houses two Smithsonian Institution museums—the National Portrait Gallery and the American Art Museum. Collections include portraits of all U.S. presidents, along with paintings, sculptures, prints, and drawings of numerous historic figures from American history, and the works of more than 7,000 American artists.

| Aug 11, 2010

Seven tips for specifying and designing with insulated metal wall panels

Insulated metal panels, or IMPs, have been a popular exterior wall cladding choice for more than 30 years. These sandwich panels are composed of liquid insulating foam, such as polyurethane, injected between two aluminum or steel metal face panels to form a solid, monolithic unit. The result is a lightweight, highly insulated (R-14 to R-30, depending on the thickness of the panel) exterior clad...

| Aug 11, 2010

Back to Nature: Can wood construction create healthier, more productive learning environments?

Can the use of wood in school construction create healthier, safer, more productive learning environments? In Japan, there's an ongoing effort by government officials to construct school buildings with wood materials and finishes—everything from floors and ceilings to furniture and structural elements—in the belief that wood environments have a positive impact on students.

| Aug 11, 2010

Nurturing the Community

The best seat in the house at the new Seahawks Stadium in Seattle isn't on the 50-yard line. It's in the southeast corner, at the very top of the upper bowl. "From there you have a corner-to-corner view of the field and an inspiring grasp of the surrounding city," says Kelly Kerns, project leader with architect/engineer Ellerbe Becket, Kansas City, Mo.

| Aug 11, 2010

Two Rivers Marketing: Industrial connection

It was supposed to be the perfect new office. In July 2003, Two Rivers Marketing Group of Des Moines, Iowa, began working with Shiffler Associates Architects on a 14,000-sf building to house their rapidly growing marketing firm. Over the next six months they put together an innovative program that drew on unprecedented amounts of employee feedback.

| Aug 11, 2010

AIA Course: Historic Masonry — Restoration and Renovation

Historic restoration and preservation efforts are accelerating throughout the U.S., thanks in part to available tax credits, awards programs, and green building trends. While these projects entail many different building components and systems, façade restoration—as the public face of these older structures—is a key focus. Earn 1.0 AIA learning unit by taking this free course from Building Design+Construction.