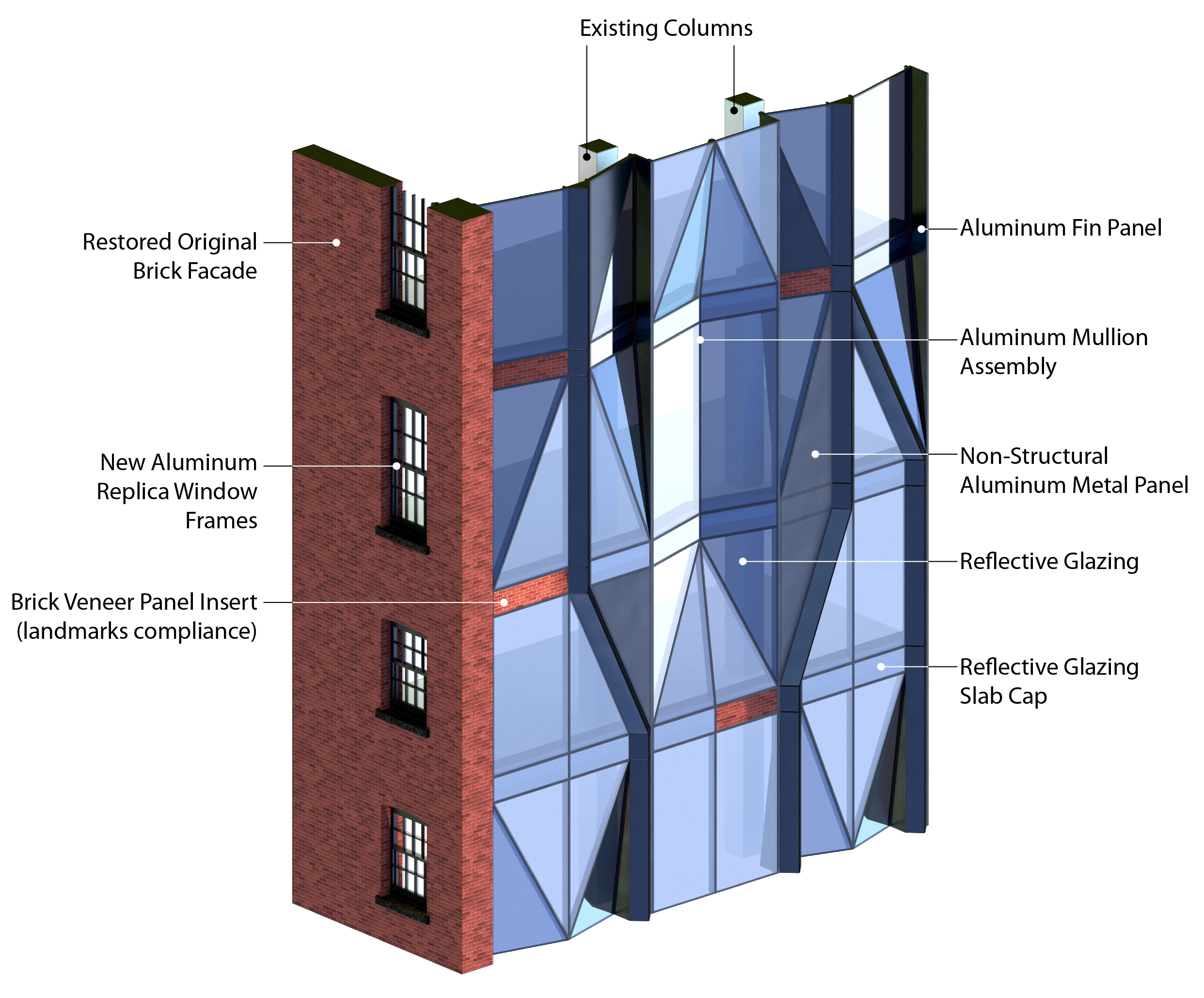

Who says the façade for a renovation and restoration project needs to be stodgy? Certainly not New York-based architecture firm ODA, which recently finished its conversion of the former Arbuckle Sugar Refinery on New York City’s East River into 10 Jay Street, a Brooklyn waterfront jewel box with 10 stories of open floor plates.

The 230,000-sf building combines three of the building’s original brick façades with a new unitized glass-and-steel waterfront curtain wall. (The original waterfront façade was torn off the building in the early half of the 20th century.)

The new curtain wall’s design was inspired by the form of a sugar crystal, meant to harken back to the building’s original use as a sugar refinery, while also adding a contemporary touch to the landmarked building. Additionally, through the use of parametric modeling, the façade will produce dynamic fragments of reflections of the river, the park, and the surrounding city.

The 10 Jay project had to manage a delicate balancing act to maintain the relationship between the neighborhood and the waterfront, as well as heritage and innovation. Photo: Pavel Bendov

The 10 Jay project had to manage a delicate balancing act to maintain the relationship between the neighborhood and the waterfront, as well as heritage and innovation. Photo: Pavel Bendov

“The intent was to restore the parts of the building that are historical and add a contemporary architectural element,” says Christian Bailey, AIA, LEED AP, Founding Principal, ODA.

Before 10 Jay Street’s new sugar-crystal-inspired design could be put into motion, it needed to be approved by the Landmarks Commission Board, which typically does not approve such modern interpretations in DUMBO and can hold jewel-box designs to intense scrutiny. Ultimately, the façade and interior earned 15 permits from New York City’s Landmarks Preservation Commission, with one permit noting the new look “aligns in keeping with the utilitarian character of the building.”

A new way of doing things: unitized curtain wall

ODA took advantage of the technical advances the AEC industry has developed in recent years with regards to unitizing the wall. In the past, the primary way to assemble curtain walls was through “stick building.” With this type of construction, the curtain wall frame is constructed primarily on site, piece by piece.

On the 10 Jay project, ODA decided to forgo the traditional stick building technique and instead opted for a unitized construction approach. The firm, after a global search for a manufacturer that could produce what was needed within budget, selected KPA Studio to construct the curtain wall.

‘10 Jay Street honors the relationship between neighborhood and waterfront, heritage and innovation.’ — Christian Bailey, AIA, LEED AP, ODA

Engineering and fabrication assembly took place in a factory in a controlled environment. The curtain wall units were then transferred to the site, which enabled “superior quality and facilitated ease of installation once on site,” says Bailey.

The unitized construction approach and the fact that the waterfront façade was installed simultaneously while the landmark restorative work was done on the other three façades helped the project stay on schedule and within budget.

In order for the new glass-and-steel façade to connect to the existing brick façades (and for restorative work to continue during installation), tolerances needed to be built in. “Items such as building and thermal movement and seismic anchoring requirements needed to be incorporated within the tolerance set in the design,” says Bailey. “Once this has been engineered, then you can start to incorporate the marriage of the two wall types as it pertains to weatherability and waterproofing.”

Weatherability and waterproofing are an important consideration when designing and installing an exterior assembly. The 10 Jay Street façade included a couple curveballs the team needed to consider: the myriad angles required to achieve the sugar crystal design, the fact that the new façade would connect to a restored brick exterior, and the building’s location right on the riverfront in New York’s flood zone.

The building’s location on the East River means the façade will be subjected to high winds and moisture, making the connection points between the restored brick walls and the new glass exterior critical. Source: ODA

The building’s location on the East River means the façade will be subjected to high winds and moisture, making the connection points between the restored brick walls and the new glass exterior critical. Source: ODA

“Resiliency was at the forefront of our thought process when designing the building,” says Bailey. The waterfront façade was specially engineered to resist the high winds and moisture coming off the river, and because a unitized approach was taken, stringent quality was maintained as the curtain wall was assembled in the factory before being transferred to site. This meant, despite the multifaceted design and the combination of new construction and renovation, the façades came together and formed a waterproof seal without issue.

ODA hopes the resulting building, a successful marriage between old and new, will act as an example of how cities around the world can recover and readapt buildings without completely obfuscating a given building or neighborhood’s heritage.

“10 Jay Street honors the relationship between neighborhood and waterfront, heritage and innovation,” adds Bailey. “A delicate balance of glass, steel, brick, and spandrels gives the building gravitas without compromising industrial heritage.”

Photos: Pavel Bendov

Photos: Pavel Bendov

Related Stories

Great Solutions | Jun 6, 2017

Good vibrations: Portable tuned mass damper provides lightweight, cost-effective way to reduce structural vibrations

Developed by a team at Virginia Tech, the PTMD has been shown to reduce vibrations by as much as 75%.

Building Tech | Feb 23, 2017

Designing an inclusive, automated city

How can cities of the near future put an emphasis on equality while also reaping the abundant benefits of technological progress?

Sponsored | | Jan 31, 2017

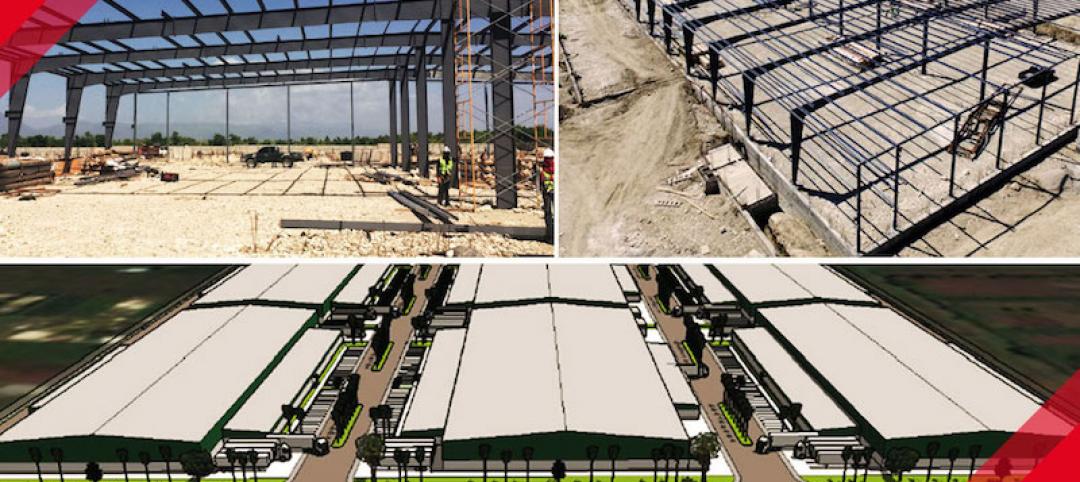

From devastation to hope in Haiti

GF Construction, led by Charles and Jerry Fombrun, designed an industrial manufacturing development in Haiti that spans one million square feet, providing both a bank and a medical facility for employees, and housing for staff.

Game Changers | Jan 19, 2017

Piezoelectric hits the road

GTRI recently got the OK from the Georgia Department of Transportation to test embedded PZ material supplied by Tencate in a stretch of road and rest stop surfaces at West Point, Ga.

Building Tech | Nov 9, 2016

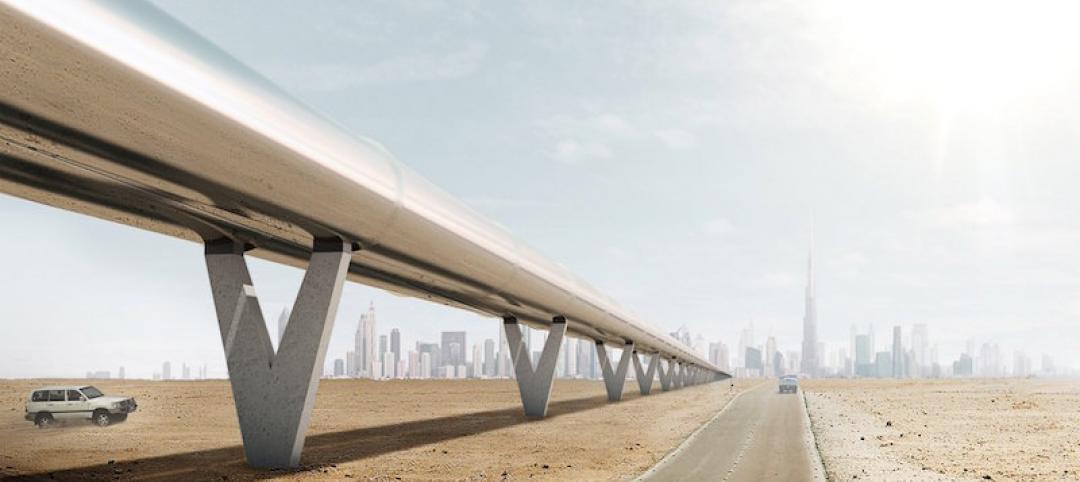

Dubai to Abu Dhabi in 12 minutes: A hyperloop from Hyperloop One and BIG could make it possible

The pods can reach speeds of up to 1,100 kilometers per hour.

Building Tech | Aug 26, 2016

NBBJ’s Goldilocks sensor technology can help employees find a workspace that is just right

The technology measures light levels, humidity and temperature, motion, and sound.

Cultural Facilities | Aug 1, 2016

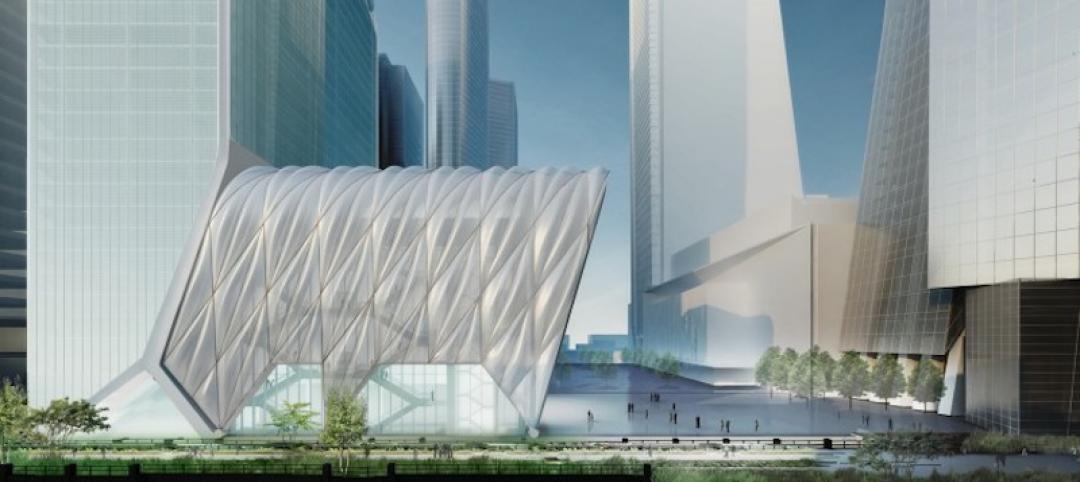

A retractable canopy at Hudson Yards will transform into a large performing and gallery space

The Shed could become the permanent home for New York’s Fashion Week event.

Building Tech | Jul 14, 2016

Delegates attending political conventions shouldn’t need to ask ‘Can you hear me now?’

Each venue is equipped with DAS technology that extends the building’s wireless coverage.

Sponsored | AEC Tech | Jun 9, 2016

With all these sharks in the water… (No Predictions Here...Part 2)

Rather than fighting to control the proliferation of apps, perhaps we should be training our eyes to look for signs of long-term viability among all the fins in the water

Building Materials | Jun 1, 2016

MIT study: Microscopic structure of natural materials can inspire better concrete

Bones and sea sponges are highly organized at the molecular level, while concrete consists of random composites.