The U.S. Department of Energy’s Research Support Facility (RSF), in Golden, Colo., is arguably America’s most significant building of the last decade, at least in terms of energy consumption.

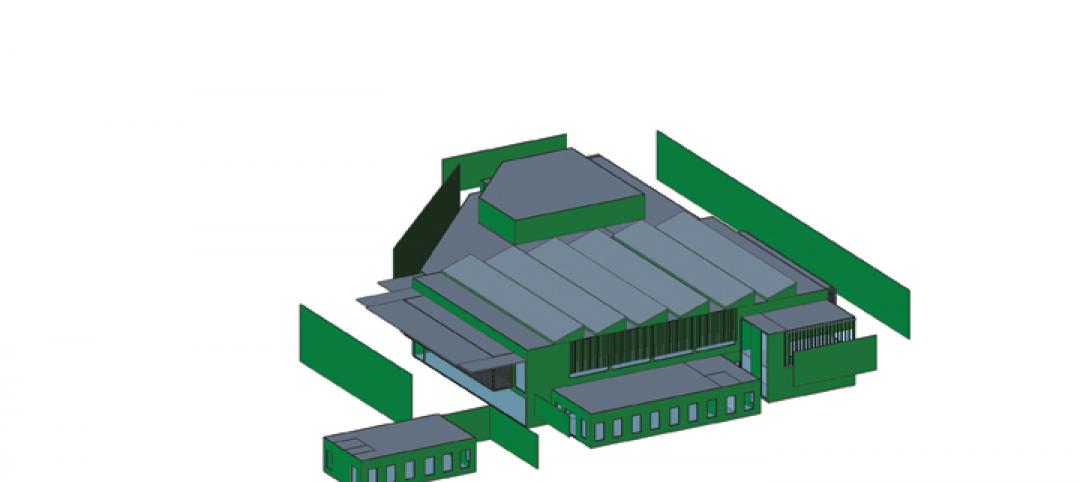

The 220,000-sf, slanted H-shaped office building, on the site of the DOE’s National Renewable Energy Laboratory, produces as much or more energy than it uses—to be specific, 35 kBtu/sf/year, which is 50% below ASHRAE 90.1-2004. The building, which also includes a data center that serves the entire campus, can accommodate 825 staff; it provides 61% more space to the NREL building stock yet adds only 6% in energy demand (which is provided by photovoltaics). Yet it came in at $57.4 million in construction costs, $64 million furnished—or $288/sf complete.

More importantly, the Building Team achieved these remarkable numbers through rigorous energy-conservation methods that brought the RSF’s energy use down by about 80% compared to a conventional building. Only after all energy-saving strategies were applied were renewable energy sources used. In all cases, only readily available, made-in-the-USA technologies and systems were used.

The DOE and NREL held a national design competition to pick the team, setting forth 26 project objectives in a fast-track, multi-bid proposal. Three objectives were deemed “mission critical”: a LEED Platinum rating, Energy Star First “Plus,” and safe work performance. The other 23 were termed “highly desirable”—such as providing room for at least 742 staff—or “if possible,” notably net-zero energy use, “most energy-efficient building in the world,” and a LEED Platinum “Plus” rating. Moreover, the project had to demonstrate that a “distinctively new class of real estate” was feasible and replicable by the private sector.

The winning team, led by design firm RNL and GC Haselden Construction (with engineering from Stantec Consulting), vowed to meet or exceed all 26 objectives. This was risky, since the team would be paid only 50% of the cost of completing the preliminary design; if the DOE didn’t like it, the feds could terminate the contract with no additional payment.

The Building Team evaluated and tested a multitude of technologies before choosing the systems that would go into the structure. These included hydronic radiant slab heating and cooling employing 45 miles of piping; a below-grade maze of heavy concrete structures to store thermal energy for passive cooling and heating; a dedicated outside air system that provides fresh air via raised floors when the windows are closed; and a thermally massive exterior wall system using insulated precast tilt-up panels.

Modular workstations, raised floor systems, and demountable walls were tested via full-scale mockups to provide optimal daylighting, thermal comfort and control, sound control, and indoor air quality. Occupied spaces are no more than 30 feet from an operable window. A mechanical system opens the windows on cool summer nights.

Working intensively with subcontractors, the team installed a standing seam metal roof 90 days ahead of schedule so that photovoltaics could be installed on time. Two of the technologies used in the RSF—transpired solar collectors and electrochromic windows—were co-developed by NREL scientists. Nearly 600 windows were placed, many of them crowned with specially designed “bonnets” to control interior heat buildup (see http://www.bdcnetwork.com/article/windows-keep-green-goals-view).

As impressive as the technological innovations were, the real breakthrough had to do with the team’s embrace of the DOE performance-based procurement process. In a radical departure from standard DOE procedures, the Building Team negotiated with DOE over a two-month period to redefine standard construction contracts, federal acquisition regulations, and RFP contract terms.

The final contract contained more than a dozen specially crafted clauses, and the new contracting method—performance-based design-build—proved so successful that it has become the new NREL model for subsequent high-performance DOE construction projects, including a new building at NREL that Haselden and RNL are working on. In fact, the team’s performance was rated “superior” on each of the 26 objectives, qualifying them for $2 million in contract incentives.

“This would have to be one of the most collaborative projects I’ve seen in recent years,” said juror Michael Damore, Executive Managing Director of A/E firm Epstein, Chicago. Said J.A. Detamore, PhD, PE, PMP, Director, NREL Infrastructure and Campus Development, “The level of innovation and creativity that went into this [project] is simply outstanding. The project represents the highest level of partnering I have ever been part of in my 29 years of experience.”

The lesson of the NREL Research Support Facility is clear: If the U.S. government can build a net-zero energy office building at market-rate cost, why can’t the private sector do so?

Related Stories

| Nov 2, 2010

Wind Power, Windy City-style

Building-integrated wind turbines lend a futuristic look to a parking structure in Chicago’s trendy River North neighborhood. Only time will tell how much power the wind devices will generate.

| Nov 2, 2010

Energy Analysis No Longer a Luxury

Back in the halcyon days of 2006, energy analysis of building design and performance was a luxury. Sure, many forward-thinking AEC firms ran their designs through services such as Autodesk’s Green Building Studio and IES’s Virtual Environment, and some facility managers used Honeywell’s Energy Manager and other monitoring software. Today, however, knowing exactly how much energy your building will produce and use is survival of the fittest as energy costs and green design requirements demand precision.

| Nov 2, 2010

Yudelson: ‘If It Doesn’t Perform, It Can’t Be Green’

Jerry Yudelson, prolific author and veteran green building expert, challenges Building Teams to think big when it comes to controlling energy use and reducing carbon emissions in buildings.

| Nov 2, 2010

Historic changes to commercial building energy codes drive energy efficiency, emissions reductions

Revisions to the commercial section of the 2012 International Energy Conservation Code (IECC) represent the largest single-step efficiency increase in the history of the national, model energy. The changes mean that new and renovated buildings constructed in jurisdictions that follow the 2012 IECC will use 30% less energy than those built to current standards.

| Nov 1, 2010

Vancouver’s former Olympic Village shoots for Gold

The first tenants of the Millennium Water development in Vancouver, B.C., were Olympic athletes competing in the 2010 Winter Games. Now the former Olympic Village, located on a 17-acre brownfield site, is being transformed into a residential neighborhood targeting LEED ND Gold. The buildings are expected to consume 30-70% less energy than comparable structures.

| Oct 27, 2010

Grid-neutral education complex to serve students, community

MVE Institutional designed the Downtown Educational Complex in Oakland, Calif., to serve as an educational facility, community center, and grid-neutral green building. The 123,000-sf complex, now under construction on a 5.5-acre site in the city’s Lake Merritt neighborhood, will be built in two phases, the first expected to be completed in spring 2012 and the second in fall 2014.

| Oct 21, 2010

GSA confirms new LEED Gold requirement

The General Services Administration has increased its sustainability requirements and now mandates LEED Gold for its projects.

| Oct 18, 2010

World’s first zero-carbon city on track in Abu Dhabi

Masdar City, the world’s only zero-carbon city, is on track to be built in Abu Dhabi, with completion expected as early as 2020. Foster + Partners developed the $22 billion city’s master plan, with Adrian Smith + Gordon Gill Architecture, Aedas, and Lava Architects designing buildings for the project’s first phase, which is on track to be ready for occupancy by 2015.

| Oct 13, 2010

Editorial

The AEC industry shares a widespread obsession with the new. New is fresh. New is youthful. New is cool. But “old” or “slightly used” can be financially profitable and professionally rewarding, too.

| Oct 13, 2010

Prefab Trailblazer

The $137 million, 12-story, 500,000-sf Miami Valley Hospital cardiac center, Dayton, Ohio, is the first major hospital project in the U.S. to have made extensive use of prefabricated components in its design and construction.