Roofing industry expert Joseph Schwetz maintains that there is an important difference between what building codes require and what the construction insurance industry—notably mutual insurance firm Factory Mutual—demands—and that this difference can lead to problems in designing a roof.

Founded in 1835 by Zachariah Allen, Factory Mutual, Johnston, R.I., insures about 15-20% of the nation's building stock. However, “they insure a majority of the larger buildings, and their insured properties are ones that cannot afford the major financial loss of being down—not even one day,” says Schwetz, a 30-year veteran of the roofing industry and manager of technical services at Canton, Mass.-based Sika Sarnafil.

To protect its assets and clients and shield itself from significant financial loss, FM has developed its own very strict building requirements that exceed those of most building codes. Over the years the insurer has continued tightening its requirements, thus making its influence felt strongly within the AEC industry.

“It's important for those involved in roof design to know the difference between FM [requirements] and building code,” says Schwetz. “However, I'm not sure many roofing designers do.” And therein lies the problem.

Designing a roof to meet FM requirements when it's not required can drive up project costs. He says that the standard building code, which follows ASCE 7-05, is not as stringent as FM's requirements and should work for most projects.

Schwetz offers eight valuable tips every roofing designer needs to know about dealing with FM specs and building codes.

1 Be sure to ask if the building is insured by Factory Mutual.

This may seem obvious, but Schwetz says many roofing designers don't think to ask about the building's insurance carrier when they're sorting out roof geometry, waterproofing, materials selection, and the dynamics of wind uplift, among other concerns. Be warned, however, that even if your project isn't FM insured, many other insurance firms reference FM specs or have agreements with FM, so you need to check the building's insurance status.

2 Don't design the roof to FM standards if you don't have to.

“The roofing industry, including manufacturers, is guilty of creating generic, boilerplate specifications that state a building shall meet FM 1-90 UL Class A,” says Schwetz. However, once wind-speed calculations are determined for the building, it may not need to meet this high standard. As a result, using boilerplate specs can lead you to overdesign the roof system, thereby needlessly driving up construction costs.

3 Before you start designing, check out FM's requirements online.

Go to the firm's RoofNav site: https://roofnav.fmglobal.com/RoofNav/Login.aspx. See accompanying box for advice on how to use this tool.

4 Be aware that FM is the only body that can approve roof assemblies for its insured buildings.

Virtually all roofing manufacturers use Factory Mutual's wind-uplift testing facility in West Gloucester, R.I. “This way, manufacturers have an approved assembly that can meet both FM and building code, which is important in the market,” says Schwetz. As far as FM is concerned, it is not sufficient to have a product tested at a lab certified by the International Code Council; to get FM's OK, it has to be done in their test facility. “For the purpose of efficiency, most manufacturers test at FM's lab,” says Schwetz.

5 Understand that FM specs will always be more stringent than building code specs.

Schwetz says some proposed changes to wind load calculations should be incorporated into ICC in 2012, but they are minor—and they “won't be as tough as FM requirements.”

6 Be on the lookout for changes in FM's specifications.

Factory Mutual does not issue changes on a regular basis; more likely, such changes are issued based on conditions in the insurance industry. For example, Hurricane Katrina prompted FM to tighten up its standards.

Schwetz says that because FM has such an influence on the roofing industry, the insurer is open to working with roofing manufacturers. “They want to be very involved with the industry and in the specification development process” he says.

Nonetheless, FM is, according to Schwetz, “very particular” about whom they will insure. “Not every owner will fit FM's criteria,” says Schwetz, who adds that once he knows FM is insuring one of his projects, he gets FM on the case. “There's a huge advantage to involving FM's field people right away,” he says.

7 Understand Factory Mutual's approval process.

After reviewing a roofing package and approving it, the insurer sends field engineers to make follow-up inspections to ensure the roofing system is installed according to FM guidelines.

8 Be prepared to do extra work to get approval for a green roof.

Schwetz says that FM is close to finalizing its requirements for vegetated roofing. In the meantime, he says, “If you can make a case”—especially with regard to how much weight the green roof adds and how it meets wind uplift requirements—“they should be able to make a decision and come up with an acceptable design on a case-by-case basis.”

Related Stories

| Nov 14, 2011

VanSumeren appointed to Traco general manager

VanSumeren will draw on his more than 20 years of experience in manufacturing management and engineering to deliver operational and service excellence and drive profitable growth for Traco.

| Nov 11, 2011

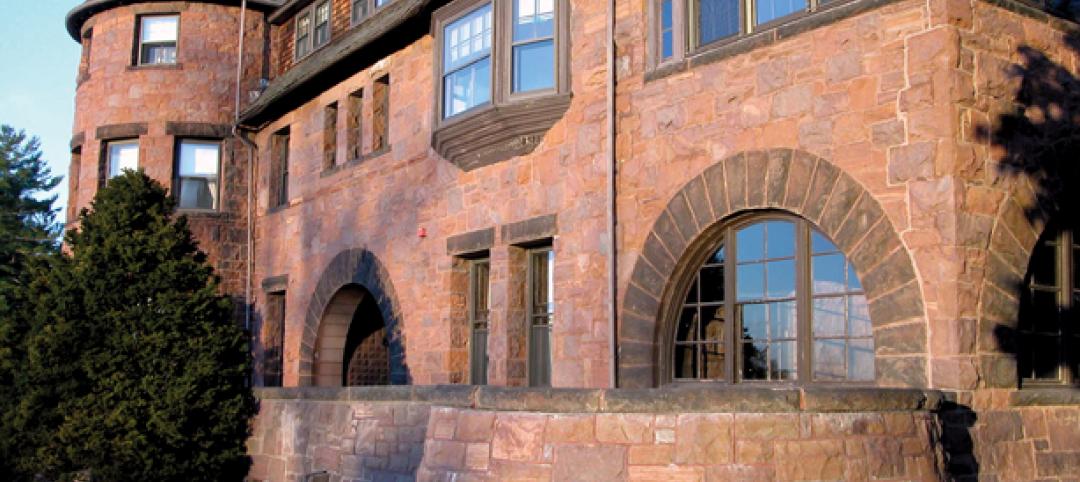

AIA: Engineered Brick + Masonry for Commercial Buildings

Earn 1.0 AIA/CES learning units by studying this article and successfully completing the online exam.

| Nov 11, 2011

How Your Firm Can Win Federal + Military Projects

The civilian and military branches of the federal government are looking for innovative, smart-thinking AEC firms to design and construct their capital projects. Our sources give you the inside story.

| Oct 25, 2011

Universal teams up with Earthbound Corp. to provide streamlined commercial framing solutions

The primary market for the Intact Structural Frame is light commercial buildings that are typically designed with concrete masonry walls, steel joists and steel decks.

| Oct 17, 2011

THOUGHT LEADER: Allan Bilka, Senior Staff Architect and Secretariat to the IGCC

Allan Bilka, RA, is a Senior Staff Architect and Secretariat to the International Green Construction Code (IgCC) with the International Code Council, based in the ICC’s Chicago district office. He also serves as staff liaison to the ICC-700 National Green Building Standard. He has written several ICC white papers on green building and numerous green-related articles for the ICC. A registered architect, Bilka has over 30 years of combined residential design/build and commercial consulting engineering experience.

| Oct 14, 2011

AIA Continuing Education: optimizing moisture protection and air barrier systems

Earn 1.0 AIA/CES learning units by studying this article and passing the online exam.

| Oct 12, 2011

Building a Double Wall

An aged federal building gets wrapped in a new double wall glass skin.

| Oct 7, 2011

GREENBUILD 2011: Transparent concrete makes its North American debut at Greenbuild

The panels allow interior lights to filter through, from inside.

| Oct 6, 2011

GREENBUILD 2011: Dow Corning features new silicone weather barrier sealant

Modular Design Architecture >Dow Corning 758 sealant used in GreenZone modular high-performance medical facility.

| Oct 4, 2011

GREENBUILD 2011

Click here for the latest news and products from Greenbuild 2011, Oct. 4-7, in Toronto.