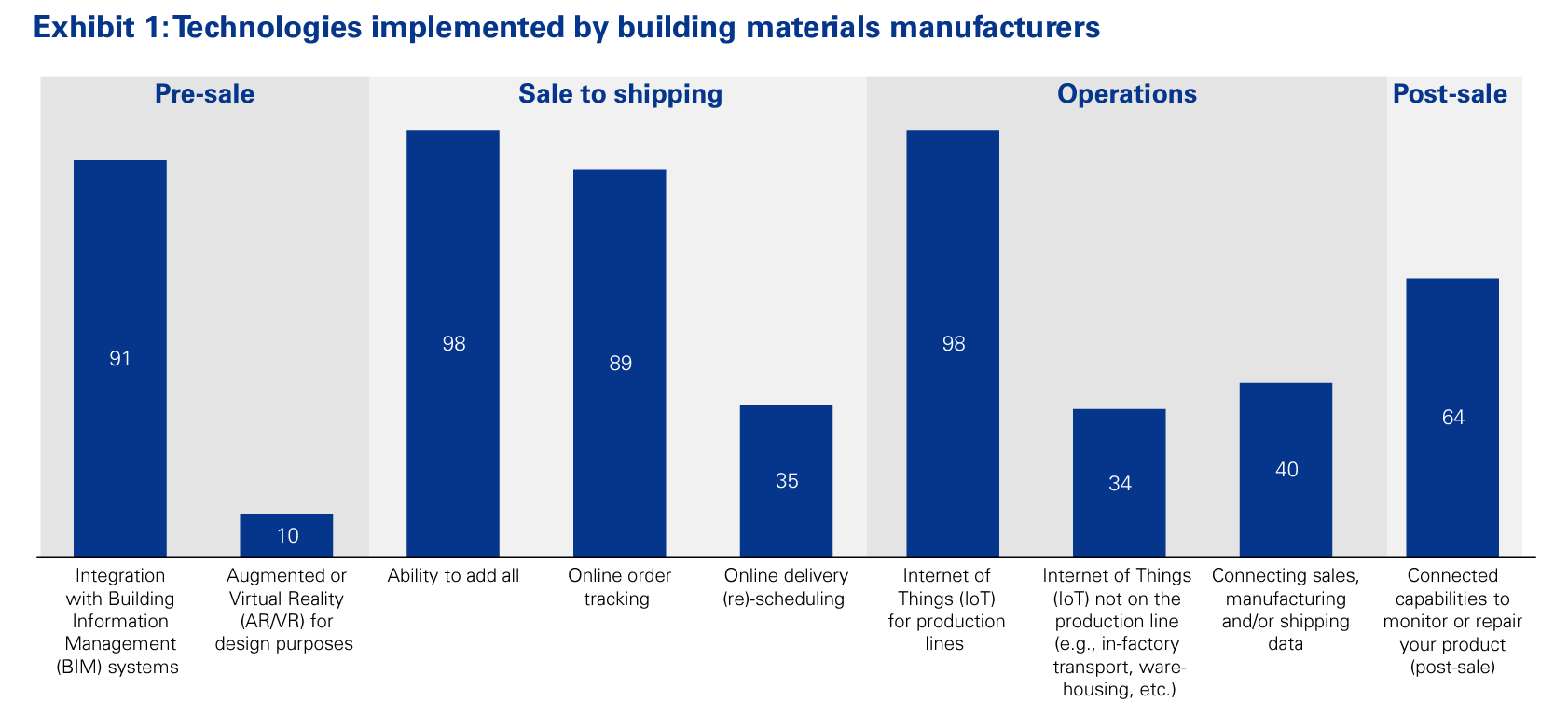

KPMG, an organization of firms that provide audit, tax and advisory services, surveyed 100 U.S. building material manufacturing executives to understand what technological investments they had made—or were planning to make—and why.

These digital developments range from Building Information Management (BIM) integration to e-commerce and online delivery. Regardless of the method, KPMG pulled out four surprising insights from the results of the survey.

Overall, half of building product manufacturers plan to invest in one or more areas of technology in the next three years. The survey breaks down technology categories by product journey, from pre-sale, sale to shipping, operations, and post-sale groups. Pre-sale technology would include BIM systems and AR/VR design, for example.

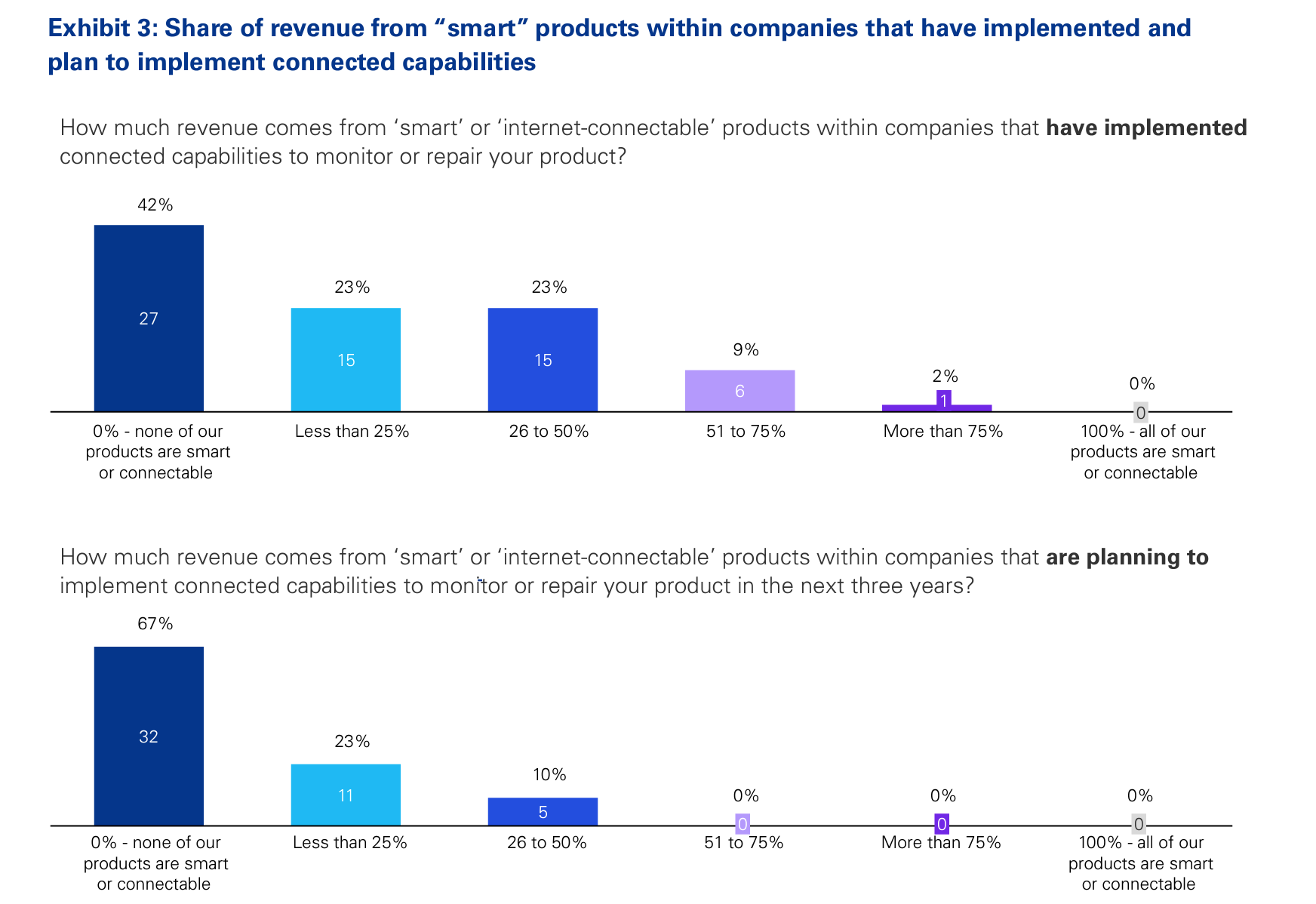

1. Connected capabilities can work without ‘smart’ products

In the study, KPMG expected to see post-sale connected capabilities to only be applicable to smart products, such as thermostats, security systems, and air conditioners. However, 42% of respondents that have already implemented such connected capabilities have no products with any smart features.

Likewise, 67% of respondents who plan to implement these technologies in the next three years said the same.

2. Technology can drive both revenue and cost benefits

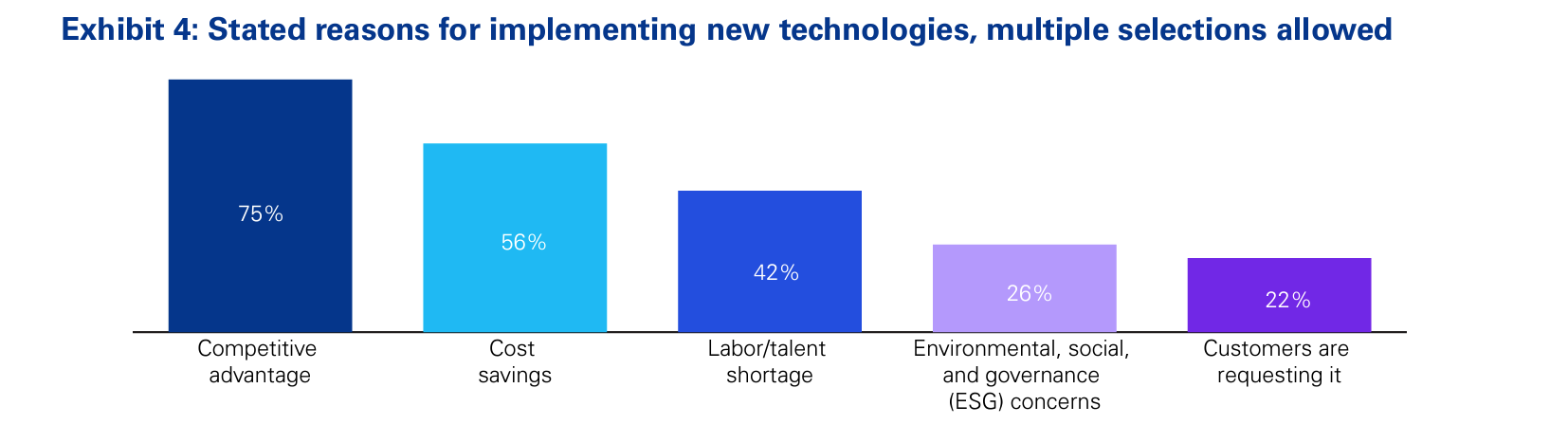

What are the largest influences behind implementing new technologies? Over half (56%) of building materials manufacturers report cost savings as one of the biggest reasons. Forty-two percent attribute their influence towards the labor/talent shortage, while 75% of manufacturers planning to implement new technologies do so for a competitive advantage.

Alternatively, one-quarter (26%) of respondents listed ESG concerns as an influence, and just 22% said that customers were requesting it. KPMG finds that the reasons did not differ significantly across company types or types of technology.

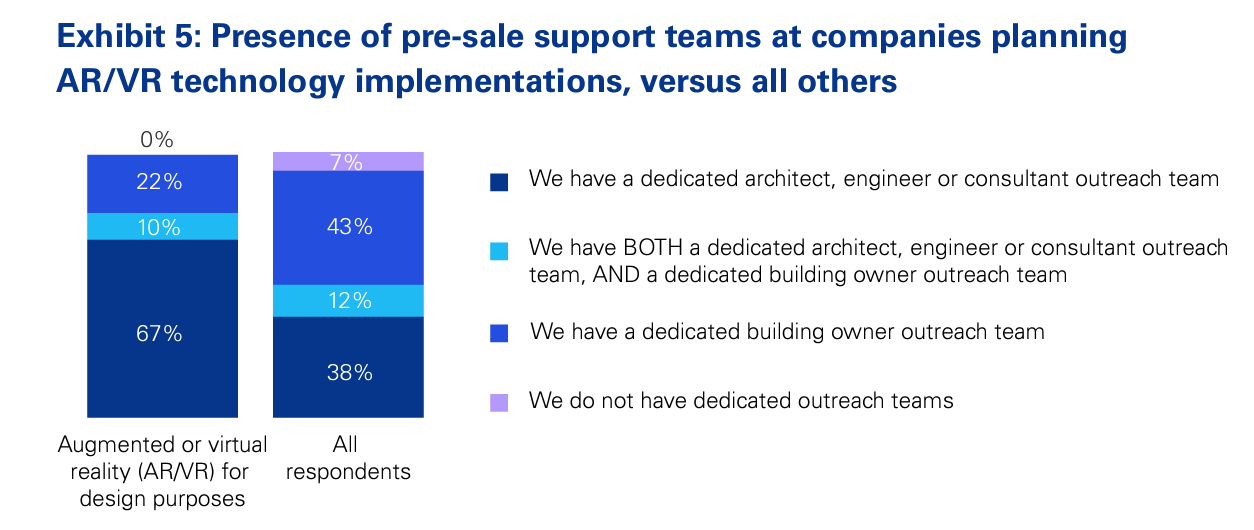

3. AR/VR technology is in addition to—not a replacement for—outreach teams

Rather than displacing the role of sales support teams, AR/VR tech was found to be an additional tool for architects, engineers, and consultant outreach teams. The survey shows that 78% of companies investing in AR/VR and remote monitoring to help the pre-sale process have a dedicated support team.

This is above the general average of 50% of respondents with the same teams, but without AR/VR technology in place, according to the report.

4. Companies overestimate their technological sophistication levels

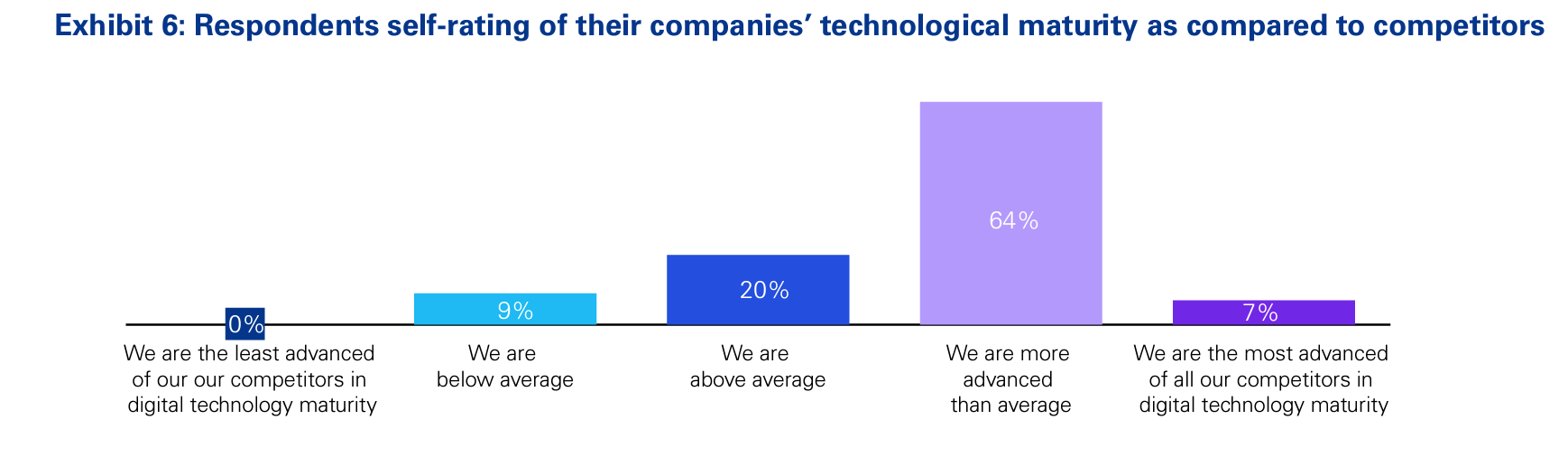

When asked about their companies’ technological maturity compared to competitors, a majority of respondents (70%) believe they are more advanced than average. Only 9% believe their company is below average, but no respondents claimed to be “the least advanced of all our competitors in digital maturity.”

Furthermore, KPMG saw that the more technologies a company selected as “implemented,” the more likely they were to self-rate as being above average or best-in-class.

“While quantity certainly helps, quality of execution is a determining factor in how effective these technologies are,” says Serena Crivellaro and Len Prokopets, Managing Directors, Advisory, KPMG. “Unfortunately, with technological deployments being so broad-based across the industry, competitors may be more advanced than companies expect.”

Click here to view the entire report.

Related Stories

AEC Tech | Apr 12, 2019

NBBJ creates Design Performance Group whose goal is to connect building design with occupant wellbeing

The firm also wants to advance energy efficiency in its projects.

AEC Tech | Apr 10, 2019

Speaker Update! Accelerate AEC Innovation Conference, May 13-14, NYC

BD+C's third-annual Accelerate AEC Innovation Conference (May 13-14, NYC) will explore AI in architecture, offsite construction, smart buildings, AEC business innovations, big data in construction, and much more.

AEC Tech | Mar 26, 2019

Embracing collaboration tools from outside the AEC industry

Let's take a look at the available technologies from outside AEC that are seeing greater adoption within the industry.

AEC Tech | Mar 24, 2019

5 ways designers and builders can use business intelligence with data they already have

Tricky construction budgets, large project teams, and unique designs needing extensive coordination are all problems increasingly being handled with new software tools and data.

AEC Tech | Feb 8, 2019

BI(m): BIM data without models

A new breed of data tools creates a valuable opportunity for the next wave of BIM and facilities management, one where “pure data” is at the center, writes John Tobin of SMRT Architects.

AEC Tech | Jan 9, 2019

Our robotic future: Assessing AI's impact on the AEC profession and the built environment

This is the first in a series by Lance Hosey, FAIA, on how automation is disrupting design and construction.

3D Printing | Dec 7, 2018

Additive manufacturing heads to the jobsite

Prototype mobile 3D printing shop aims to identify additive manufacturing applications for construction jobsites.

AEC Tech | Sep 27, 2018

BD+C editors want your input on AEC technology

Please help us improve our editorial coverage by taking this brief survey.

Sponsored | AEC Tech | Sep 14, 2018

Sponsored webinar: Benefits of traceable construction

In this free 60-minute webinar, Keith Alcorn of FARO Technologies will talk about the concept of traceable construction and how 3D reality capture solutions provide portable, efficient, secure, and forward-looking solutions for data collection, pre-processing, and evaluation in the design, build and operating phase. September 18, 2:00 EST.

AEC Tech | Jul 24, 2018

Weidt Group’s Net Energy Optimizer now available as software as a service

The proprietary energy analysis tool is open for use by the public.