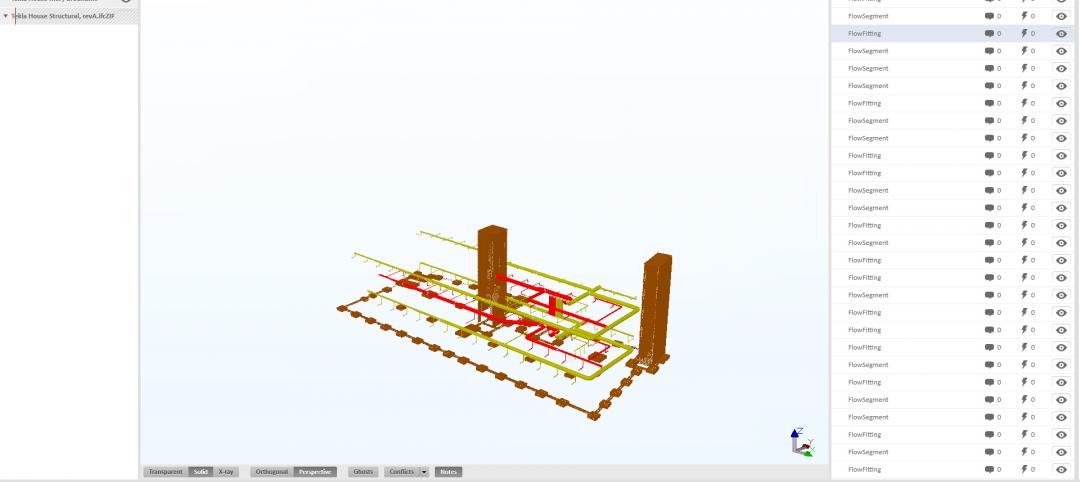

Tremco Commercial Sealants & Waterproofing has unveiled its new state-of-the-art, fully automated Sustainable Building Solutions Test Facility.

The facility is designed for controlled testing of air and moisture infiltration/exfiltration in air barrier systems and building enclosures. Such penetrations lead to energy loss, structural deterioration, and poor indoor air quality. Developed in collaboration with the Air Barrier Association of America (ABAA) and working in conjunction with building scientists at Oak Ridge National Laboratory (ORNL), the Sustainable Building Solutions Test Facility is a technically advanced and fully automated laboratory designed to measure energy loss and sustainability of the built environment.

“This test facility is a testament to Tremco’s commitment to the sustainability of the built environment,” said Chuck Houk, president of Tremco Commercial Sealants & Waterproofing. “Most building envelope problems are moisture-related, either caused by air leakage or exterior moisture penetration. The testing done at this facility will help to ensure building materials are performing at optimal levels and eliminate some of the trial and error as well as risk associated with building design and construction.”

Components tested at the facility will be exposed to different levels of wind conditioning and moisture to determine resistance to specific elements, including rain, high winds, and other environmental conditions. Specifically the facility will conduct ASTM E2357, E283, and E331 tests. It will do so using 300 to 400 channels for simultaneous data control, precise measurement devices, and infrared photography.

In addition to testing air barrier assemblies, the facility has the capability to test the following connection points between air/vapor building protection systems to assure continuity throughout the building enclosure:

- Roof-to-wall tie-ins

- Foundation-to-wall tie-ins

- Corners

- Window-to-wall interfaces

- Penetrations

Related Stories

| Sep 12, 2011

Living Buildings: Are AEC Firms up to the Challenge?

Modular Architecture > You’ve done a LEED Gold or two, maybe even a LEED Platinum. But are you and your firm ready to take on the Living Building Challenge? Think twice before you say yes.

| Sep 7, 2011

KSS Architects wins AIA NJ design award

The project was one of three to win the award in the category of Architectural/Non-Residential.

| Sep 7, 2011

Administration, Maintenance and Operations Facility in South Bend achieves LEED Platinum

The facility achieved 52 LEED points, including those for site selection, energy, materials and resources and innovation.

| Jul 22, 2011

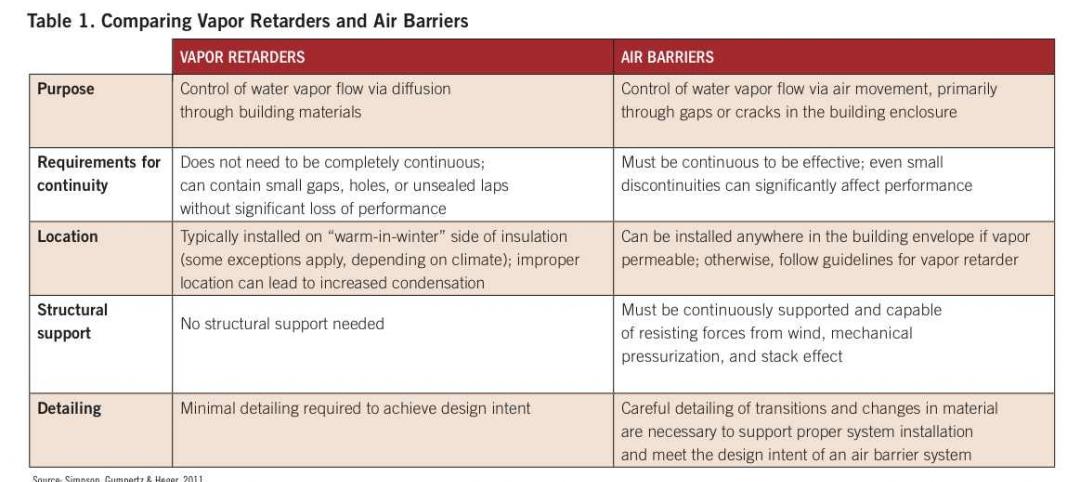

Air barrier systems: Your guide to optimal performance

Expert advice on how to control wasteful air leakage in the building envelope.

| Jul 22, 2011

Five award-winning modular innovations

The Modular Building Institute's 2011 Awards of Distinction highlight fresh ideas in manufactured construction projects.