The Pavilion, Penn Medicine’s $1.5 billion hospital, hopes to make waves in the medical world once it is completed. With a cornucopia of state-of-the-art features, the Foster + Partners-designed hospital is expected to provide a new level of patient care.

Before any of that happens, though, the hospital has already accomplished something no Philadelphia hospital, or any other structure for that matter, has accomplished before. On July 8, the Pavilion set the record for the largest concrete pour in Philadelphia’s history, Philly Voice reports.

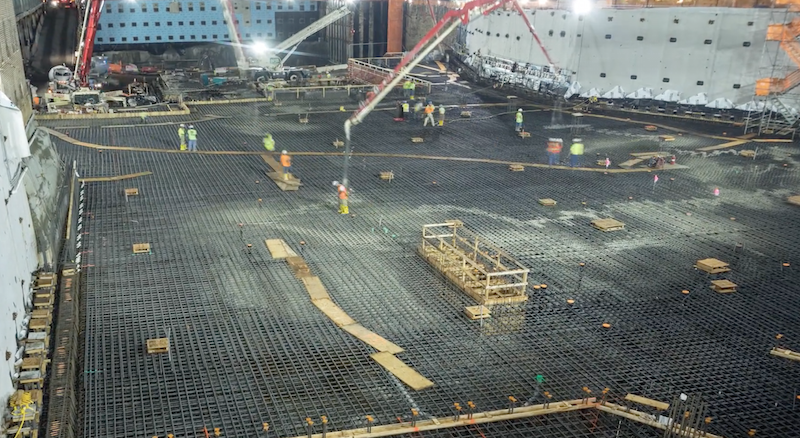

Over 120 workers from LF Driscoll and Balfour Beatty poured 6,540 cubic yards of concrete from 654 concrete trucks over a period of 14 straight hours. The concrete, which is being used to create the foundation of the new building, was poured onto 965 tons of reinforcement steel.

The previous record, according to Curbed Philadelphia, was set in 2016 at the site of the W and Element Hotels. That pour took 24 hours, involved 600 cement trucks, and used 5,850 cubic yards of concrete

The Pavilion is not scheduled to open until 2021.

Related Stories

Wood | Jan 13, 2017

Steel and concrete's take on tall wood

The American Institute of Steel Construction contends that the steel industry is a “world leader” in using recycled material and end-of-life recycling, and has made strides to lower greenhouse gas emissions below regulatory requirements.

Concrete Technology | Dec 5, 2016

Telescopic walls could help combat the damages of floodwaters

The project is currently under development by a Ph.D. candidate at the University of Buffalo.

Sponsored | Concrete | Nov 11, 2016

Fabcon Precast is built for speed

It’s difficult for other construction methods to match Fabcon’s speed, especially when weather is a determining factor–as it almost always is in Canada.

Codes and Standards | Oct 12, 2016

Making concrete greener

The high energy-consuming material can be made more sustainably.

Concrete | Aug 2, 2016

Concrete Association builds case against cross-laminated timber

The campaign asserts that not enough is known about CLT in construction

Concrete | Jul 20, 2016

Arup ensures Mexico City concrete skyscraper can withstand seismic activity

Double-V hangers and irregularly spaced gaps allow the structure to bend.

3D Printing | Jun 14, 2016

By 2021, 3D concrete printing is projected to be a $56.4 million industry

The 3D concrete printing industry is expected to more than double in size within the next five years.

Concrete | Jun 13, 2016

American Concrete Institute releases new Guide to Shotcrete

Includes information on application procedures, testing.

Concrete | Jun 7, 2016

Concrete Institute publishes document providing concrete curing guidance

New curing monitoring techniques included.

Building Materials | Jun 1, 2016

MIT study: Microscopic structure of natural materials can inspire better concrete

Bones and sea sponges are highly organized at the molecular level, while concrete consists of random composites.